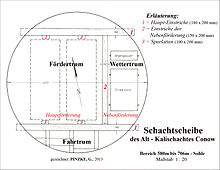

Shaft disk

In mining, a shaft disk is the cracked representation of the shaft cross-section of a shaft with shaft extensions and installations . The shaft disk is divided into individual segments, so-called dreams .

Cross-sectional shapes

A distinction is made between different cross-sectional shapes in manhole construction; there are manhole disks with a rectangular cross-sectional shape, a square cross-sectional shape, an elliptical cross-sectional shape, a polygonal cross-sectional shape and a round cross-sectional shape. Angular cross-sectional shapes were used when wood was used to support manholes. The rectangular cross-sectional shape is preferred for shafts with a length of tonnes. This is necessary because the conveying vessels slide on the lying surface. The square cross-sectional shape is used for sloping manholes. This has the advantage that with the same area, there is less space and therefore less wood is required for the construction of the shaft extension. The elliptical cross-sectional shape could not prevail due to its inexpediency. The polygonal cross-sectional shape is the result of a lost carpentry for the subsequent masonry, which also could not prevail.

With a round cross-sectional shape, manholes have the largest surface area with the smallest circumference. As a result, this cross-sectional shape offers considerable advantages over the other cross-sectional shapes, both when sinking and during expansion. One advantage is that no corners have to be knocked out. Since this work process is very time-consuming, round shaft cross-sections are cheaper. Since both the rock pressure and the water pressure of the groundwater are evenly distributed over the shaft lining, the round shape increases the strength of the shaft joints. Due to these advantages, seigere shafts are almost exclusively built with a round cross-sectional shape. A special design was the design of the shaft disc using four flat arches. This type of construction was often used in the shafts of the Westphalian coal mining industry for the watertight lining of the shafts. This type of construction was necessary because the coal mountains were often covered by marl rich in water and the wood construction could be better adapted to this shape. This design was no longer used with the introduction of the shaft walling.

Design of the shaft disc

The design of the shaft disk depends on several factors. First of all on the type of shaft, then on the use of the shaft and also on the type of hoisting machine. In the case of blind shafts, the shaft section is divided differently than in the case of day shafts. Blind shafts often only have a single-chute conveyance with a conveyor cage and a counterweight. Day shafts usually have four conveyor baskets. In addition, day shafts must also allow a greater conveying capacity and considerably more supply lines are built into them. When designing the shaft section, it depends on whether the shaft is used purely as a material and cableway shaft or as a pure delivery shaft.

Division of the shaft disc

The shaft disk is divided into so-called rubble, each section has a special task. There is a driving section, a conveyor section and, if necessary, a spiral section. When dividing the shaft section, care is taken in advance that each strand has a sufficiently large area. The travel center must be placed in such a way that you can get to the other ruins from it without much difficulty. The location of the conveying strand depends on how much is conveyed in the shaft. The size of the conveyor strand is determined on the basis of the specified dimensions for the funds. The required shaft cross-section is determined from the total size of all rubble during planning.

Size of the shaft disk

The size of the shaft disc depends essentially on what the shaft is to be used for. Another aspect is the cost of building the manhole. The more expensive it is to create a shaft, the cheaper a shaft disc with a large cross-section is. Since two conveying devices can often be installed with large shaft sections, the additional costs for the larger cross-section pay off in the course of the period of use due to a better degree of utilization. Large shaft panels also enable so-called large baskets to be installed.

Individual evidence

- ^ A b c Walter Bischoff , Heinz Bramann, Westfälische Berggewerkschaftskasse Bochum: The small mining dictionary . 7th edition, Verlag Glückauf GmbH, Essen 1988, ISBN 3-7739-0501-7 .

- ↑ a b c d e f g Carl Hellmut Fritzsche: Textbook of mining science. Second volume, 10th edition, Springer Verlag, Berlin / Göttingen / Heidelberg 1962, pp. 17–22.

- ↑ a b c d e Hans Bansen (Ed.): The pit expansion . Second increased and improved edition, published by Julius Springer, Berlin 1909, pp. 92–94.

- ↑ a b c Gustav Köhler: Textbook of mining science. 2nd edition, published by Wilhelm Engelmann, Leipzig 1887.

- ↑ a b c d e Ernst-Ulrich Reuther: Textbook of mining science. First volume, 12th edition, VGE Verlag GmbH, Essen 2010, ISBN 978-3-86797-076-1 , pp. 37-44.

- ↑ a b Heinrich Otto Buja: Engineering manual mining technology, deposits and extraction technology. 1st edition, Beuth Verlag GmbH Berlin-Vienna-Zurich, Berlin 2013, ISBN 978-3-410-22618-5 , pp. 229-231.

- ^ A b Albert Serlo: Guide to mining science . First volume, published by Julius Springer, Berlin 1869.

- ↑ F. Heise, F. Herbst: Textbook of mining science with special consideration of hard coal mining. First volume, published by Julius Springer, Berlin 1908.