Shaft extension

As shaft structure is referred to in the mining with shafts the lateral lining of the shaft wall. Only a few shafts that are in solid rock salt can do without shaft expansion. Depending on the shape of the shaft and the lateral rock pressure , different materials are used for the shaft construction.

Basics

So that the side joints do not collapse in manholes , they must be lined with suitable materials. The expansion of the shaft is intended to prevent the ingress of water and additionally protect against the fall of stone slabs. The shaft extension also serves to accommodate the grooves and other shaft installations . The requirements for the construction material are greater for day shafts than for blind shafts . The shaft construction used also significantly influences the cross-sectional shape of the shaft. The expansion is also a major cost factor when sinking the shaft. The shafts are expanded either with closed cast iron or steel segments or steel rings, which are provided with a delay as required and backfilled with suitable materials. In the case of older shafts, the shaft lining was also bricked up. Up until the second half of the 19th century, the shaft lining was made of wood , which was then called the shaft timbering. Today, the joints in newly constructed manholes are secured by means of concrete lining.

Shaft timbering

The wooden shaft timbering is inserted into the shaft with great precision so that the joints cannot break in. Shaft timbering can only be used in square shafts. Bringing in the shaft timbering is problematic, as the shaft is sunk from top to bottom, but the fixed timbering is built from bottom to top. To prevent the impacts from breaking in when sinking, especially in loose rock, an auxiliary carpentry, the so-called lost carpentry, is installed. The lost carpentry is a kind of formwork consisting of yokes and caps; if there is strong pressure from the side, the side walls are expanded with lines. The individual shafts are supported one above the other with corner bolts. In the case of rectangular manholes, the yokes are attached to the short joints and the caps to the long joints. As soon as solid rock is reached, the lost carpentry is replaced by a fixed carpentry.

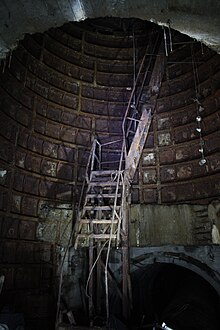

Shaft walling

The shaft lining is installed in a similar way to the shaft lining. It rests on a fixed abutment so that it has sufficient support. When the masonry is placed in loose rock, a sufficiently stable abutment cannot initially be placed. Here, a square made of oak is created, which has the exact shape of the shaft and whose yokes are firmly placed in the stage holes. This shape serves as a template for the masonry. Since the shaft wall is also bricked from bottom to top, a lost carpentry is also first brought in to secure the joints, which then remains behind the wall. The resulting spaces are backfilled with suitable materials. In the case of rectangular manholes, depending on whether a manhole is deep or long , either all or only some of the joints must be bricked. Round or oval shafts are advantageous for the shaft wall, as the lateral rock pressure is more evenly distributed over the wall. The shaft walling is less suitable for rectangular shafts, as straight walls offer less resistance to the lateral rock pressure than round ones.

Iron construction

In the case of iron construction, specially shaped construction segments, the so-called manhole rings, are inserted. The individual manhole rings are made of profile steel such. B. U-iron or curved double T-beams. Each manhole ring consists of several segments that are screwed together using special straps. Between the individual manhole rings there are spacers made of U-iron, which are also screwed to the rings. Warping mats are placed behind the manhole rings and the space between them is backfilled. Compared to the shaft wall, the extension with iron segments has great advantages: with the same stability and strength, the iron extension requires less space. As a result, the sunk shaft diameter can be smaller than that of the shaft wall with the same clear shaft width. In addition, the iron lining can be finally brought in when the sinking is done and does not require any auxiliary formwork. The internals such. B. the lines can be screwed directly to the manhole rings and do not have to be anchored in the masonry. This means that the shaft is ready for use much earlier. In rectangular shafts, iron structures from railroad tracks, double T-beams or U-irons were used in some cases. The extensions were connected either directly or by means of lashing via angle brackets.

Concrete lining

In the case of newer manholes, especially in areas with a strong water inflow, the manhole lining is very often made of concrete. This is necessary because high demands are made on the shaft extension in terms of safety, precision and efficiency. The shaft lining is made with shotcrete produced on site or with finished concrete segments, so-called tubbing segments . A distinction is made between two processes in the shotcrete process, the wet and the dry process. In the wet process, the sprayed concrete is mixed with water beforehand and sprayed onto the manhole wall via a nozzle; in the dry process, the water is only added after it has been sprayed out of the nozzle. In both processes, the spraying process can be carried out either manually or by machine. For the development of geothermal energy there are shaft construction processes in which special segments are used.

Individual evidence

- ^ A b Walter Bischoff, Heinz Bramann, Westfälische Berggewerkschaftskasse Bochum: The small mining dictionary . 7th edition, Verlag Glückauf GmbH, Essen 1988, ISBN 3-7739-0501-7 .

- ↑ a b c d e f g h i j k Fritz Heise, Fritz Herbst: Textbook of mining studies with special consideration of hard coal mining. Second volume, fifth increased and improved edition, published by Julius Springer, Berlin 1932, pp. 142–155.

- ↑ a b Horst Roschlau, Wolfram Heinze, SDAG Wismut (Hrsg.): Knowledge storage mining technology. 1st edition. German publishing house for basic industry, Leipzig 1974, pp. 96–98.

- ^ A b c Carl Hellmut Fritzsche: Textbook of mining science. Second volume, 10th edition, Springer Verlag, Berlin / Göttingen / Heidelberg 1962, pp. 152–165.

- ^ The Upper Harz Mining Museum: The Shaft Extension ( Memento from August 13, 2006 in the Internet Archive ) (accessed on October 8, 2012).

- ↑ a b c Charles Pierre Mathieu Combes, Carl Friedrich Alexander Hartmann: Manual of mining art or the theory of exploration and extraction of usable minerals . First volume, published by Bernhard Friedrich Voigt, Weimar 1844, pp. 276–296.

- ↑ a b c d e Ernst-Ulrich Reuther: Textbook of mining science. First volume, 12th edition, VGE Verlag GmbH, Essen 2010, ISBN 978-3-86797-076-1 , pp. 281-297.

- ^ A b Wilhelm Leo: Textbook of mining science. Printed by and published by G Basse, Quedlinburg 1861, pp. 250-254.

- ^ Emil Stöhr, Emil Treptow : Basics of mining science including processing . Spielhagen & Schurich publishing bookstore, Vienna 1892

- ↑ Patent: DE102004054541A1 May 11, 2006 Shaft construction and operating procedures (last accessed on October 8, 2012).