Switchboard

The switchboard is part of an electrical installation in electrical engineering and in mechanical and plant engineering. Switching elements of the control system (e.g. contactors , relays , but also fuses) are housed on it; the name is derived from these elements.

The control panel is usually housed in the control cabinet ; However, the control panel (for example the door of the switch cabinet) also contains some of the switching elements ( displays , switches, buttons ). Such control panels are therefore also often referred to as control panels. For these there are panel-mountable components and devices, for example operator terminals, indicator lamps, measuring devices, buttons, switches or touch screens .

Control panel vs. Distributor

Switchboards differ from distributors in that only electrical energy is distributed in them : while there is usually only one operating voltage in the distributor, load and control circuits with different voltages are usually present in the switch cabinet and thus on the switchboard . This can be AC or DC voltage .

The control panel is always part of the control of a single machine or of machine groups and is therefore not only used for energy supply . As a rule, however, the control panel also contains the individual fuses and, for example, the motor protection switch of the controlled machine .

Control panel vs. Control panel

Since it used to be common to switch an electrical system directly and manually, the control panel is often also a control panel. Today, however, operating elements are often not connected to the machine directly, but rather via a control circuit, or they are operated via a computer terminal. Then the control and switch panels can be spatially separated from each other. However, such control panels can also have switching elements that intervene directly in the main circuit (e.g. the main switch ) or influence it separately ( e.g. emergency stop switch ).

If there are several control panels in a control room , they are usually designated according to their main function. In this context, the term “control panel” is often used for the control panel on which the electricity and material flows (power distribution, chemical processes, etc.) are displayed and managed. Such switchboards contain display and measuring devices (nowadays often in the form of a computer screen) often in the arrangement and representation of a simplified block diagram that shows the current and material flows and their parameters.

General

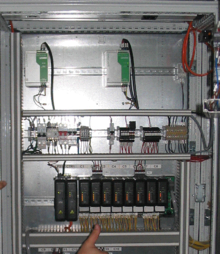

The switchboard carries the individual components of the system control and their interconnection. It should enable stable wiring with the shortest possible lines. The wiring should also not make troubleshooting unnecessarily difficult, which is why today it is carried out with individual wires that are often numbered (today mostly stranded wires ) routed in channels .

As many components as possible, which are included in the circuit diagram , are mounted on the control panel . Only the end devices (e.g. a motor ) that are located outside are connected via cables. In most cases, the control panel is housed in a control cabinet, which is set up in a location that is as easily accessible as possible. Alternatively , it is also possible to accommodate the control panel on or in the machine itself. The control elements and displays are often located in the door of the cabinet or the machine and are connected to the interior via flexible connecting cables. In this case one also speaks of a "control cabinet with control unit".

Often there is still space on the switch panel in the switch cabinet for a later expansion of the machine control - the switch panel is then suitable, for example, in its basic structure for a complete machine series and can be expanded or expanded accordingly depending on the version.

construction

Historically, the components of a control panel were individually screwed onto an insulated base plate like marble slabs. These panels were then built into the equipment cabinet. Even today, the control panels are, as far as possible, pre-assembled outside the control cabinet, as this allows easier assembly .

Today, the switchboard usually consists of a frame made of mounting rails onto which the individual components (terminals, contactors, fuses, power supplies, etc.) can be snapped. The mounting rails are arranged horizontally with cable ducts in between. The individual stranded wires are inserted into these cable ducts , thus connecting the components according to the circuit diagram . In the past, wiring harnesses were made from the cables that were already connected , but these made subsequent changes or repairs more difficult. Wiring harnesses made of solid wires were often prefabricated using gauges (pins on a board). For the control panel (often the door of the control cabinet) there are devices for control panel installation, these are mostly indicator lamps, measuring and control devices, sometimes also fuses.

For safety reasons, on switchboards that are not only operated with extra-low voltage , a plastic cover is attached over the parts that carry dangerous voltage. In this cover there are usually cutouts for the components (an alternative is a transparent, full-surface cover). The cover should cover the non-insulated connections of the components so that no contact with the parts that are live is possible. Nevertheless, an overview of the switching status of the individual components should be possible to make troubleshooting easier. If the control panel is made of an electrically conductive material, it must be connected to the protective conductor if the components are not operated with low voltage.

English term

The term English control panel is ambiguous and is used both for the term control panel and in this article, but it often means a control panel, control panel or instrument panel that is defined in German. This conceptual overlap arose in English through the structures common in the early days of electrical engineering, such as control panels for high-voltage systems on open switchboards.

literature

- Viktor Kadainka: Elements of electricity and electrical engineering for miners. A. Hartleben's publishing house, Vienna and Leipzig 1905