Lock disc striking mechanism

The lock disc striking mechanism is an old type of striking mechanism in a wheel clock , which is mainly found in antique table and wall clocks. With a lock disc hammer mechanism , in contrast to the likewise old rack hammer mechanism, it is not possible to repeat a blow (usually by operating an operating element, see repetition hammer mechanism ).

To control the matching the time pacing rate to use the so-called locking plate (also: closing disc or counter wheel ), which is cut in the margin. While the striking mechanism is running and the clock strikes, the lock disc rotates slowly around its axis. The locking lever (also: holding lever or drop lever ) slides along its edge until it hits an incision and engages. This stops the clock striking. The number of clock strikes is controlled by the distance between the incisions.

Components

Other components besides the lock washer are:

- Accessory wheel (connected to lock washer)

- Nail wheel or pin wheel

- Heart wheel or ratchet or Herzrad or cam lever (for Black Forest plants) or first initial wheel

- Thrust wheels

- Windscreen or flywheel or windscreen drive

- Release lever

function

The lock washer ensures that the striking mechanism can make more than one blow after it has been triggered. It rotates together with the accessory wheel (attached to the same shaft) and can prevent the second release lever b + d from returning to the rest position together with the first release lever. This is the case when the knife on arm K hits the circumference of the lock washer. Then the first guide wheel continues to turn. There are further blows (second to twelfth) until the knife has again found a gap in the lock disc, which has continued to turn, and the second release lever has also returned to the rest position.

Because the lock disk needs time to turn so far that the knife is no longer over a gap, the "heart disk" is necessary as an additional device. It rotates on the same shaft with the first idler wheel. The pin s, which is in contact with the heart disc, is located on the extended lever d. The second release lever has been kept in release by her since the warning until shortly before the end of the first rotation of the first run-up wheel. From now on, the lock disc can provide the release, the knife can no longer return to the gap belonging to the rest position. The distance between the gaps corresponds to the number of additional strokes (one to eleven). The survey between the two gaps before 1 a.m. and 2 a.m. is omitted (large gap), since at 1 a.m. you can only hit once. 78 strokes are performed in a cycle of twelve hours. The lock disc rotates once and the first idler wheel 78 times. The locking plate is also closing disc , because it makes their gaps closing with a hit series.

If the movement is also intended for a half-hour beat (second pin on the minute wheel), 90 beats per cycle are performed. The translation from the lock washer to the first idler gear is greater. This now rotates 90 times per cycle, while the lock disc rotates once as before. The ten normal gaps each correspond to two beats (half-hour beat and first beat of every full hour), the large gap between 12 o'clock and 2 o'clock now corresponds to four beats (two half-beats, one beat for 1 o'clock and the first beat at 2 o'clock). The lock washer in the illustration is shaped for 90 strokes. Each of the 90 points indicates one ninetieth of the circumference and the execution of a stroke.

36 ° = 360 ° / 10 = 360 ° / (1 + 2 + 3 + 4)

6 ° = 60 ° / 10 = 60 ° / (1 + 2 + 3 + 4), if the disc rotation is designed for 6 impact cycles, s . adjacent picture

Angular divisions of the lock washer:

- Hourly stroke: 4.62 ° = 360 ° / 78 strokes (1 + 2 + 3 + 4 + 5 + 6 + 7 + 8 + 9 + 10 + 11 + 12)

- Hourly and half-hour strokes: 4 ° = 360 ° / 90 strokes (1 + 1 + 2 + 1 + 3 + 1 + 4 + 1 + 5 + 1 + 6 + 1 + 7 + 1 + 8 + 1 + 9 + 1 + 10 + 1 + 11 + 1 + 12 + 1)

- Quarter-hour strike with separate striking mechanism: 36 ° = 360 ° / 10 strikes (1 + 2 + 3 + 4) for, for example, the "Vienna strike" or the "Westminster strike"

6 ° = 60 ° / 10 = 60 ° / (1 + 2 + 3 + 4), if the disc rotation is designed for 6 impact cycles, see chap. adjacent picture

The divisions between 4 and 6 ° show how precisely the lock washer and the drop lever must be manufactured in order to be able to reliably reproduce the desired number of strokes.

The striking mechanism is typically decoupled from the movement of the watch. It is only triggered by the minute wheel of the movement after every hour (or half an hour). After that it is left to itself. Which number of strokes occurs depends only on the current position of the lock washer. The assignment between walking gear and striking mechanism can be lost, for example if the drive of the striking mechanism has run down but the walking mechanism continues to run.

Typical causes of loss of synchronization, a summary:

- Running down of the striking mechanism and simultaneous running of the walking mechanism

- The beat can lose synchronization if the clock hands are turned against the normal direction of movement. Example: If the hands are set from 14:05 to 13:50, a beat is triggered, which is the beat for 14:30. If after ten minutes 14:00 is displayed, the beat sounds for 15:00. So the deviation is one hour. (Caution: clockworks can be damaged if the time is set against the normal direction of movement of the hands.)

- If the time is adjusted so quickly in the normal direction of movement that the respective triggered impact cannot be fully executed, synchronization is also lost.

This asynchronicity can be eliminated by manually triggering blows on a designated grip area of the release lever of the clockwork or on a thread attached to it.

application

Today quarter-hour lock disc strikes are still used for the 4/4 Westminster strike. After different tone combinations have been played (four tones on four different bells), the lock disc is checked using a lever to determine whether the number of tone combinations to be played has already been reached: four at quarter of an hour, eight at half an hour, twelve at three quarters of an hour and sixteen at full hour .

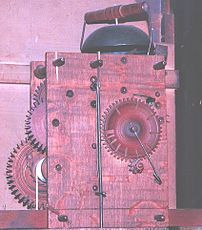

Metal clockwork: Renaissance

lock disc, the knife on the leftWooden floor clock

mechanism lock washer with relatively deep gaps

z. At the time of the recording, 11am is struck

Individual evidence

- ↑ René Beguin: Clocks. Rembrandt Verlag, 1979; Original edition: Restoration of the Horloges, Montres et Pendules. Office du Livre, 1979

- ^ Hermann Brinkmann: Introduction to the watchmaking apprenticeship. Wilhelm Knapp Verlag, 1980

- ^ Zdeněk Martínek and Jaroslav Řehoř: Mechanical watches. VEB Verlag Technik Berlin, 1980

- ↑ Emile James: The doctrine of the percussion. Callwey publishing house, Munich 1903; Reprint of the original edition: Verlag Georg DW Callwey, Munich 1988