Striking mechanism (clock)

The striking mechanism is an independent mechanism in a wheel clock , with the help of which the time is reported only as a clock strike (old church clocks without dial) or in addition to the visual display (clock hands). The strike occurs automatically at discrete times after being triggered by the walking mechanism , usually no more than every quarter of an hour. In the case of percussion mechanisms with repetition, the last blow performed is repeated on request. The most elaborate versions also strike the minutes that have now passed (minute repeater).

General

A wheel clock can be equipped with one or more striking mechanisms with which a large number of striking patterns is possible. The following description contains only examples with an impact mechanism and deals with the basic functions and their technical solutions, in particular the construction details for the "warning" and control of the impact sequence. Such wheel clocks are mainly pendulum clocks (tower, wall, grandfather and table clocks).

In the simple case, only the full hours are struck: the hour strike from once for 1 o'clock to twelve times for 12 o'clock. The striking mechanism can be extended to indicate half an hour (an intermediate strike each) or even quarter hours (once for the first quarter, twice for the second quarter and three times for the third quarter). In order to avoid confusion with the striking of the full hours from 1:00 to 3:00, the quarter hours are usually struck on a second body of sound.

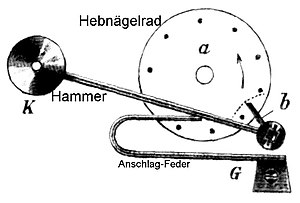

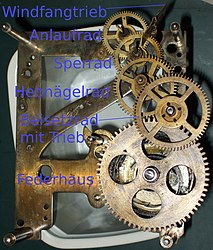

The hammer hitting a sound body is moved by a wheel with pins ( lever wheel ) (see Fig. 1). Its flexible, flexible handle falls on an elastic stop that is attached just in front of the sound body. This ensures that after the impact it no longer has any contact with the sound body, so that it can vibrate without being dampened.

Striking mechanisms can basically be divided into two groups, namely into

The distinction only applies to the control of the number of beats beyond one beat, because at least one beat (1 o'clock) is always required.

Among the rack mechanisms there are the ratchet strikes and the whip strikes, which are triggered without warning. With very old clocks there are also lock disc strikes without warning. Sometimes both types can be found on a watch, for example when the quarter-hour strike is controlled by a lock disc, but the hour-strike mechanism is a rack-and-pinion mechanism.

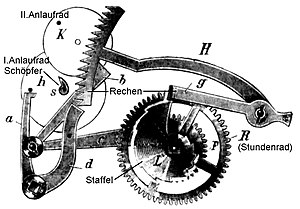

Control of the first strike

The lever wheel is followed by further translation stages in the gear train (see Fig. 2). At the end is the vestibule , which needs a high speed to act as an aerodynamic brake to limit the speed of the running hammer mechanism. The two intermediate gears are also used to trigger the striking mechanism. In order to be able to trigger in a stable manner, there are two trigger levers, the second is pushed by the first. In the time between the first contact of the arm g with a trigger pin on the minute wheel of the movement (see Fig. 3) and its return to the rest position, the striking mechanism starts up briefly (the warning ). The first run-up wheel is released from the blocking arm d soon after the arm g begins to lift, but after a short run it is blocked again by the second run-up wheel and with it the striking mechanism. The second thrust wheel is held by the arm h. It only becomes free again after arm g has fallen back, after which the actual process begins. The sudden relapse is a clearly delimited triggering moment. The previous uplift takes too long to trigger in a stable manner.

The number of lifting nails is as large as the translation from the lifting nails to the first idler wheel. There is only one hit, because the first guide wheel is blocked again after one revolution.

Control with lock disc (lock disc striking mechanism)

The lock disc is on the same shaft as the accessory wheel , so it only turns when the striking mechanism is in motion. With it it is achieved (as with the scale of the hammer mechanism) that the hammer mechanism can make more than one blow after being triggered. It can prevent the second release lever b + d from returning to the rest position together with the first release lever (see Fig. 4). This is the case when the knife on arm K hits the circumference of the lock washer. Then the first guide wheel continues to turn. There are further blows (second to twelfth) until the knife has again found a gap in the lock disc, which has continued to turn, and the second release lever has also returned to the rest position.

Because the lock disk needs time to turn so far that the knife is no longer over a gap, the "heart disk" is necessary as an additional device. It rotates on the same shaft with the first idler wheel. The pin s, which is in contact with the heart disc, is located on the extended lever d. The second release lever has been kept in release by her since the warning until shortly before the end of the first rotation of the first run-up wheel. Only from now on does the lock disc need to provide clearance, i.e. This means that the knife can no longer return to the gap belonging to the rest position. The distance between the gaps corresponds to the number of additional strokes (one to eleven). The survey between the two gaps before 1 a.m. and 2 a.m. is omitted (large gap), since at 1 a.m. you can only hit once. 78 beats are performed in a cycle of 12 hours. The lock disc rotates once and the first idler wheel 78 times. The locking plate was originally called final disc , because it makes their gaps closing with a hit series.

If the movement is also intended for a half-hour stroke (second pin on the minute wheel, see Fig. 3), 90 strokes per cycle are performed. The translation from the lock washer to the first idler gear is greater. This now rotates 90 times per cycle, while the lock disc rotates once as before. The ten normal gaps each correspond to two beats (half-hour beat and first beat of every full hour), the large gap between 12 o'clock and 2 o'clock now corresponds to four beats (two half-beats, one beat for 1 o'clock and the first beat at 2 o'clock). The lock washer in Figure 5 is shaped for 90 strokes. Each of the 90 points indicates one ninetieth of the circumference and the execution of a stroke.

The lock disc striking mechanism is triggered by the minute wheel of the walking mechanism after every hour (or half an hour). The number of strokes depends only on the current position of the lock disc. The assignment between the movement and the striking mechanism of a gear clock can be lost, for example if the drive of the striking mechanism has run down but the mechanism continues to run.

Control with relay disk (rake hammer mechanism)

With the rake hammer mechanism with the rake and the relay , more than one blow can occur after triggering (see Fig. 6). The graduated disk sits on the hour wheel of the movement and therefore, unlike the lock disk of the lock disk striking mechanism, rotates permanently. This ensures that the mutual assignment of the displayed and posted time cannot be lost.

As with the lock washer striking mechanism, the first blow takes place after the actual process begins. The second (up to twelfth) blow can only occur when the rake has fallen and the release lever d + a of the first run-up wheel is blocked in the release position. The second highest (to lowest) segment of the scale corresponds to a corresponding arithmetic position. With the Creator , the rake is lifted back one step (tooth) with each rotation. In its uppermost position it releases the lever d + a again. The appropriate number of strokes has been made, the striking mechanism is at rest again.

For an additional half-hour stroke, for example, the release lever with the second pin on the minute wheel is only moved so far that the first starting wheel is free, but the rake does not fall yet. For the extension to quarter beats, an additionally formed scale is advantageous (see Fig. 7): Between successively deeper cuts for the additional hour beats at 2 a.m. to 12 p.m., the scale is not cut (first quarter), followed by a single deep (second quarter) and a double deep (third quarter) incision.

Lock washer striking mechanism

The lock washer striking mechanism is the older type. The control of the beat sequence takes place within this clockwork part. The acoustic display can get out of step with the visual display when the watch is being used (winding, readjusting, etc.). With the subsequent hammer mechanism, the impact sequence is specified by the walker, thus avoiding deviations between impact and display due to incorrect operation.

Synchronicity with the clockwork

The striking mechanism is typically decoupled from the movement of the watch, so that only the last strike performed is used to determine which strike is to be performed next. There are different typical causes for the loss of synchronization:

- Running of the striking mechanism and simultaneous running of the walking mechanism,

- The beat can lose synchronization if the clock hands are turned against the normal direction of movement. Example: If the hands move from 14:05 to 13:50, a beat is triggered which is the beat for 14:30. If after 10 minutes 14:00 is displayed, the beat sounds for 15:00. So the deviation is one hour. (Caution: clocks can be permanently destroyed if the time is set against the normal direction of movement of the hands.)

- If the time is adjusted so quickly in the normal direction of movement that the respective triggered impact cannot be fully executed, synchronization is also lost.

This asynchronicity can be eliminated by manually triggering blows on a designated grip area of the release lever of the clockwork or on a thread attached to it.

Designation of the mechanical parts

The designation of the mechanical parts of the lock washer striking mechanism according to:

- Release lever

- Locking lever or retaining lever or drop lever

- Lock washer or lock washer or counting wheel

- Pin wheel or lever pin wheel

- Ratchet wheel or heart wheel or heart disk or lifting thumb (for Black Forest works) or first run-up wheel

- Delaisrad or initial wheel and second initial wheel

- Flywheel or vestibule or vestibule drive

In some lock washer striking mechanisms, the release lever and locking lever are combined in one lever that can assume different defined positions for the different functions.

Different designs

Stroke sequence variants

Hour strike

Angle division for beat to the full hour:

4.62 ° = 360 ° / 78 = 360 ° / (1 + 2 + 3 + 4 + 5 + 6 + 7 + 8 + 9 + 10 + 11 + 12) Angle division for beat to the full and half an hour:

4 ° = 360 ° / 90 = 360 ° / (1 + 1 + 2 + 1 + 3 + 1 + 4 + 1 + 5 + 1 + 6 + 1 + 7 + 1 + 8 + 1 + 9 + 1 + 10 + 1 + 11 + 1 + 12 + 1)

This variant requires a particularly precise manufacture of the lock washer.

Quarter-hour strike

A quarter-hour striking mechanism is an optional additional striking mechanism to the hourly striking mechanism.

Angle division for beat to the full quarter of an hour:

36 ° = 360 ° / 10 = 360 ° / (1 + 2 + 3 + 4)

6 ° = 60 ° / 10 = 60 ° / (1 + 2 + 3 + 4) if the disc is rotating is designed for 6 impact cycles, s. adjacent picture

Rake hammer mechanism

The peculiarity of the rake impactor is that it, in contrast to the previous lock disc percussion always execute the same number of strokes even at repetition of tripping (before the next triggering by the going train). This feature allows the arbitrary repetition ( repetition ) of the blow.

The four main components of the calculating hammer mechanism are the relay, the creator, the calculating lever and the rake.

- The rake is a special lever with a toothed arch or a toothed side, whereby each tooth corresponds exactly to a hammer blow, "Bim-Bam" or "Cuckoo".

- The drop lever or rake lever locks the rake like a pawl.

- The creator is basically a gear with only one tooth or pin, rotates 360 degrees during a hammer blow and lifts the rake by one tooth.

- The relay is a worm-shaped disc with graduated radii that precisely limits the fall path of the rake depending on the time. It is often attached directly to the hour tube and thus connected to the hour hand. Striking mechanisms with a quarter-hour strike often have a separate scale with four radii that sits on the shaft of the minute wheel. For striking mechanisms that can strike every single minute, for example, the scale for the minute strike is shaped differently and sits on the shaft of the minute wheel.

Designation of the parts of the calculating hammer mechanism are:

- Hourly scale

- Release lever

- Attack lever

- Rake

- drive wheel

- Additional wheel with drive (typically only for watches with 8 or 14 days running time)

- Lifting pin wheel with drive with lifting pin

- Creator wheel with engine and creator and pen with incidence cams

- Guide wheel with drive and guide pin

- Windscreen drive; an aerodynamic brake that serves to stabilize the speed and thus the impact frequency

Videos of examples that clearly demonstrate the function:

- BimBam strike of a home clock mechanism at half an hour

- BimBam beat of a home clock on the hour (2 o'clock)

- BimBam strike of a home clock shortly after the full hour (2 o'clock), triggered by actuating the repeater

- Strike on the round gong of a grandfather clock at half an hour

- Strike on the round gong of a grandfather clock on the hour (2 o'clock)

- Strike on the round gong of a grandfather clock shortly after the full hour (2 o'clock), triggered by actuating the repeater

Calculator striking mechanisms of this type are only used in stationary clocks. Therefore, the mechanism is often actually constructed in such a way that gravity has to act in one direction in order to cause the rake and drop lever to make the falling movements that are required for the operation of the rake hammer mechanism. The release lever and hammer lever shaft often have a return spring, even on stationary watches. For movable clocks (e.g. travel clocks, pocket watches), rakes and drop levers are additionally provided with springs, which, with their spring force, ensure the appropriate movement of the rake and drop lever in every position of the clock or ensure a certain dynamic of the movement process. Mobile clocks are typically equipped with rack mechanisms in order to be able to realize the important function of the repeater.

Even with calculating hammer mechanisms, it can happen that the beat does not match the displayed hour. There are four reasons for this:

- The hammer mechanism had run down before and the rake remained in a low position (for example 12 o'clock) and then, after winding the rake hammer mechanism, also strikes 12 o'clock, for example, as soon as the blow was triggered for the first time after winding. This can happen even at half an hour. The next time a beat is triggered, the calculating hammer mechanism should sound the correct number of beats again without any corrective intervention.

- Sometimes the hour hand sits so loosely on the hour tube that the hour hand was inadvertently turned in relation to the hour tube and the hour scale when setting the clock. If this is the case, the hour hand can be turned back to the correct position with little force.

- If the minute hand of the watch is set against its normal direction of movement, a wrong beat can sound when the half or full hour is reached.

- If stroke errors only occur when manually triggering the stroke repetition before or after the full hour or at certain times of the day, the hour tube is not optimally positioned in relation to the rake.

The photo shows a clockwork from FHS with a 4/4 Westminster beat. In the left area the rake of the rake hammer mechanism can be seen, which strikes the full hours. The striking mechanism for the quarter-hour strike is on the right-hand side. This is controlled via a small lock disc. The lock washer is easily recognizable by its complicated outer contour and the four indentations, each of which ends with a quarter-hour strike. In addition to the indentations for the respective end of the quarter-hour strike, the lock disc of the quarter-hour strike also has a raised portion (cam) in the area of the quarter-hour strike of the full hour. This triggers the beat of the full hour as soon as the preceding beat of the quarter hours of the full hour comes to an end. Directly below the lock washer, the lever of the lock stop runs from the left edge of the picture to just next to the pointer mechanism. The lever of the strike stop is in the upper position and thus prevents the release lever of the quarter-hour strike from falling and thus prevents the clockwork from striking.

With Comtoise clocks, the rake is sometimes also done straight:

In Morbier watches , a release lever with two tips is used to trigger the strike at the full hour a few minutes after the full hour.

Repetition percussion

One speaks of a repeater hammer mechanism if the hammer corresponding to the current time is reproduced on request.

Historically, the repeater mechanism dates from a time before electric light. Back then, a candle had to be lit to read the time at night. This gave rise to the desire to be able to hear the current time on request.

The simplest form of the repeater hammer mechanism is a calculating hammer mechanism in which the release lever can not only be triggered by the lifting thumb of the hour tube, but also by actuating the release lever directly by hand or, for example, using a cord.

With the desire to be able to beat the current time at any time, the demands on the accuracy of the relay increased, since it should not be beaten 5 minutes to 5 a.m., for example.

Based on this requirement, the star was integrated into the striking mechanism. In a season with 12 gradations for the 12 hours, this star was attached to the same tube of the season. Depending on the design, either the star is moved one point further by a driver on the hour and then held in this position again by a spring until the next full hour, or a spring pressed against the point of the star by triggering the blow causes the positioning of Star and season.

The desire arose to show not only the full hours but also the quarter hours in the repetition beat. This then requires a separate relay and a separate rake for the quarter hours. With a repetition beat of quarter of an hour and hour there are additional demands on the movement:

- An additional mechanism must prevent the third quarter from being struck correctly 2 minutes before 3 o'clock, but incorrectly 3 hours ahead of time.

- Often there is also the requirement to always sound the quarter-hour strike and hour-strike when repeating (scheme of the grande sonnerie), while with regular triggering often no additional hourly strike should sound for the quarter hours (scheme of the petite sonnerie). This is also implemented using additional levers.

There is also a minute repeater for pocket watches. In addition to the beat of the full hour and quarter of an hour, the beat of the minutes sounds. For example, 6:53 would sound six beats for the full hours, three beats for the quarter hours and eight (53-45) beats for the minutes after the last quarter of an hour. These clocks then have an hourly scale, quarter hourly scale and minute scale. In pocket watches with a minute repeater, the strike is often realized with only two gongs:

- Strike the hour on feather # 1

- Quarter-hour strike on springs # 1 and # 2 simultaneously

- Minute strike on spring # 2

Watches that perform a regular strike in addition to the repeater are called self- strikers. Clocks that strike only on request can be equipped with a significantly simplified striking mechanism. A typical design is that the striking mechanism is only wound up by pulling out a cord. Depending on the position of the hourly scale, the cord must be pulled out to different extents until the beat is released. Extensive explanations can be found in

Blow

Clocks use various so-called beats for audible time reporting :

- Single strike or signal strike : the clockwork has neither a lock washer nor a rack mechanism. Here a single beat sounds on the hour on a bell or a gong. It is impossible to tell which hour it strikes.

- Strike with hour counting : a lock washer or rack mechanism is built in. The number and sound of the beats tell the user the exact full, half or quarter hour.

- Beat with an additional melody

Sound generation

The acoustic signal is generated, for example, by means of a round gong, rod gong, tubular gong, bells, whistles (for example with the cuckoo clock ), gong pens or music box mechanisms.

- It is essential for the round gong that the struck clay stick is curved in a round shape and is mounted in a piece of mass which is supported by a further rod in a second piece of mass. The second mass is screwed to the watch case. The round curved design of the tone stick makes it possible to accommodate very long tone sticks even in small watch cases. This is often used to achieve a particularly deep and full sound. Round gongs allow a very flat design of the watch case. There are only a few cases in which more than one round gong is built into a clock, since the arrangement of several round gongs is complex. - sample video

- The rod gong typically consists of 2, 3, 4 or 8 straight rods, which are mounted in a mass that is typically attached directly to the watch case. Rod gongs can be tuned differently during production and in such a way that the rod gong can be used very universally for a wide variety of hits. - sample video

- The tubular gong is realized using tubes that are typically hung with cords or threads.

- Bells are either mounted individually or, if necessary, several of them with spacers on top of each other. - sample video

- For the well-known cuckoo call , two pipes are required, each with its own bellows for generating the air flow. The bellows is typically placed horizontally above the whistle, the whistle vertically behind the clockwork. The bellows is slowly raised using a lever and, after the individual whistle has been triggered, is quickly lowered down using a mass piece inserted in the upper and movable part of the bellows. The resulting air flow creates the sound in the pipe. - sample video

- The pipes of the music clock share a larger bellows (in the example photo in white), and the movement controls the air flow to the individual pipes.

- The gong is in contrast to the gong wire (often mm between 1 and 2 mm) bent and fixed to a holder made of sheet metal on the watch case. The gong is often hit with a hammer made of bent sheet metal. This results in a rather tinny sound compared to the round gong. - sample video

- A music box mechanism can also be driven by a mechanism similar to a striking mechanism .

With the exception of the whistle, the sound is generated by striking a hammer. The hammer must be tailored to the specific purpose if the sound produced is to meet special requirements. The process of striking the hammer is determined by lifting the hammer, dropping the hammer and limiting the movement of the hammer shaft shortly before the hammer hits the tone stick of the gong or the bell. Because of the finely tuned dynamics of the movement and the elasticity of the wires that hold the hammer, the mass of the hammer continues to move a little, even though the shaft has already stopped moving. This results in a gentle impact of the hammer on the tone stick of the gong or on the bell. For gongs, soft leather or soft plastic material is usually attached to the hammer head in order to make the impact of the hammer on the tone stick of the gong even more gentle.

According to, the sound of the sound bodies struck with hammers can be adjusted by:

- the wire that moves the hammer is bent slightly so that the hammer hits the rod more forcefully or more gently

- the leather insert of the hammer (typ. with rod gong and round gong) is roughened with a coarse file in order to achieve a softer blow or

- the leather insert of the hammer (typ. rod gong and round gong) is made harder with a heated metal in order to achieve a hard blow or

- a very soft little piece of suede is glued to the point of impact of the hammer.

Sounds and melodies

- The bim-bam strike is common on table and pendulum clocks. Three to five hammers strike the same number of sticks, a single double strike (Bim-Bam) sounds at half an hour, and as many as the number of hours on the hour. Large grandfather clock movements with this beat, on the other hand, often sound up to eight gong sticks. Sound samples (video): (1) , (2)

- The Viennese strike is very popular with church clocks, but is also used in better home clocks. A single beat sounds at the quarter of an hour, at half an hour two, at three quarters of an hour three, and at a full four beats. The hours that have passed are usually counted in a lower pitch. There is a special form / addition to the Viennese strike at the Evangelical Church of St. Jakob in Niederstetten (Main-Tauber district, Baden-Württemberg), located directly on the market square. The striking mechanism counts - as an extension of the "Viennese strike" - at the end with a third (the lowest) bell as a repetition, the elapsed full hours, so that someone who did not notice the number of hours the first time gets a second chance here. The bells are tuned in E major as follows: h 1 (quarter hour strike) - g sharp 1 (hour strike) - e 1 (repetition of the hour strike).

- The Dutch alternating chime : Here the half hour is indicated by the fact that the next full hour is struck, but to distinguish it on a different, usually higher-sounding bell. With the English change of chime, however, the previous full hour is struck on a different bell. Most of the time, the movement is designed in such a way that the hammer can be tilted to the side and switch between the bells.

- The Bim-Bam-Bum-Schlag or three-quarters beat hits a "Bim" in the first quarter, a "Bim-Bam" in the second quarter, a "Bim-Bam-Bum" in the third quarter and only the number of hours on the hour. but not fifteen minutes.

- The Westminster beat is also known as the Big Ben beat: Here, four notes of a melody of a total of 20 notes are struck for every quarter of an hour. The subsequent counting of the hours is also struck here in a different pitch. The Westminster strike is the most popular on home clocks, but it can also be found annoying. Sound samples (video):

With some clocks you can switch between several melodies.

According to the above mentioned percussion melodies the following are mentioned:

- "Parsifal bells" strike (quarter-hour and hour-strike)

- "Ave Maria" strike (quarter-hour strike only on the 1st to 3rd quarter of an hour. No quarter-hour strike on the hour)

- "St. Michaels "strike (quarter hour and hour strike)

- "Whittington" strike (English or American version) (quarter-hour and hour-strike)

- "Trinity" strike (original of the glockenspiel or striking mechanism) (quarter of an hour and hour strike)

- "Canterbury" strike (quarter hour and hour strike)

- "Notre Dame" strike (quarter and hour strike)

- "Elite carillon" strike (quarter hour and hour strike)

- "Copenhagen City Hall Glockenspiel" chime (quarter-hour and hour-strike. "Guardian chant" at 6:00 and 12:00)

- "Potsdamer Gong" (only on the hour; the title sequence of the song "Üb 'immer Treu und Rlichlichkeit" sounds at the half hour)

- "Ticino gong" (half and full hour)

- "Glasenschlag" ( glass clock )

A particularly rare variant is the so-called "Roman" strike, which indicates the full hours based on Roman numbers : Different bells are used for the numbers I, V and X, four o'clock (i.e. IV) is then triggered by a strike on bell I and one represented on bell V, twelve o'clock (i.e. XII) by one on X and two on I, etc. Apart from the complicated mechanics, this sequence of beats is difficult for the listener to understand. It was never widely used.

Impact shutdown

With some watches, the striking mechanism can be switched off completely, partially or at certain times (for example at night). For this purpose, a manually operated metal slide usually blocks the striking mechanism. In other variants, on the other hand, only the hammers are kept away from the clay sticks with cables. For night shutdown, an additional mechanical device sometimes prevents the striking mechanism from being triggered or sometimes the impact from being carried out.

Electronic beat

Electronics have long since found their way into striking mechanisms for home clocks. For this purpose, melodies and chimes are stored on a chip in digitized form, which are played over a small loudspeaker at the appropriate time. Electronic wristwatches also often give an acoustic time signal on the hour.

Web links

Individual evidence

- ↑ René Beguin: Clocks. Rembrandt Verlag, 1979; Original edition: Restoration of the Horloges, Montres et Pendules. Office du Livre, 1979

- ^ Hermann Brinkmann: Introduction to the watchmaking apprenticeship. Wilhelm Knapp Verlag, 1980

- ^ A b Zdeněk Martínek and Jaroslav Řehoř: Mechanical watches. VEB Verlag Technik Berlin, 1980

- ↑ a b c Emile James: The doctrine of the percussion. Callwey publishing house, Munich 1903; Reprint of the original edition: Verlag Georg DW Callwey, Munich 1988

- ^ A b Gustav-Adolf Krumm: Large clock striking mechanisms - construction, mode of action, assembling and setting up gong striking mechanisms. Verlag der Deutschen Uhrmachter-Zeitung, 1935, reprint of the original edition: Verlag Georg DW Callwey, Munich 1988

- ↑ You should only make this adjustment if you have enough experience in repairing striking mechanisms.