Scroll compressor

A scroll compressor (also scroll compressor ) ( engl. Scroll "roller, spiral, screw") is a compressor , the interfitting of two interleaved spirals is, the opposite movement compresses the gas. The scroll compressor was invented by Léon Creux in 1905 and is mainly used as a compressor in refrigeration machines and heat pumps , as it can be mass-produced relatively cheaply and runs quite quietly (compared to reciprocating compressors ).

functionality

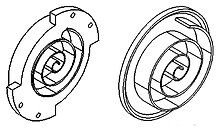

A scroll compressor works on the positive displacement principle. It consists of two nested spirals , one of which is stationary and the other is moved eccentrically on a circular path. The spirals keep a minimal distance from each other and form several rotating chambers, the volume of which decreases with each revolution. The gas to be pumped is sucked in from the outside, compressed within the spiral ducts and ejected via a connection in the middle of the spirals.

In order to achieve very high pressures - e.g. for refrigeration machines or heat pumps - several pairs of spirals can be arranged one behind the other on the same shaft so that the individual compression ratios are multiplied.

Since the spiral pairs do not touch, such compressors can work oil-free, which also enables applications in areas such as medical technology . In order to achieve a meaningful compression performance despite the low-wear, contact-free operation, precise manufacturing is required, which made it possible to use it for supercharging in motor vehicle engines only in the 1980s .

application

Scroll compressors are called

- Compressors for air conditioners

- Heat pumps and

- Vacuum pump (scroll pump) used.

In addition, they were used in the automotive sector as

- G-charger installed in some Volkswagen engines. There is no direct relationship to the twin-scroll turbocharger .

A further development of the G-Lader is the

- Handtmann spiral loader. In contrast to the G-Lader, the supercharger's displacer has a single spiral instead of a double spiral. This is intended to reduce manufacturing costs through simplified processing. The Handtmannspirallader can at low power of the internal combustion engine to be turned off to mechanical reduce losses. When the load is higher, the charger is switched on with a clutch .

Web links

Individual evidence

- ↑ Comeback of the spiral charger? Retrieved December 19, 2012.