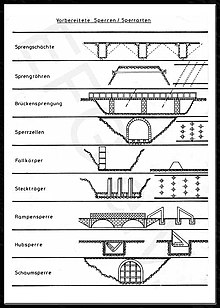

Prepared lock

Prepared barriers are devices attached to traffic systems that, once triggered, are intended to slow down and channel an opponent's attack. Blast shafts are a common form of prepared barriers .

history

In West Germany, a large number of prepared barriers were supposed to slow down and direct forces of the Warsaw Pact in the event of a defense . Since the end of the Cold War , the prepared barriers have been dismantled, often as part of road renovations, due to the disappearance of the Warsaw Pact threat.

species

The prepared barriers include blast shafts, girder barriers, ramp barriers, drop barriers and foam barriers.

The location of most of the barriers was artillery measured in order to be able to take the blocked enemy directly under fire.

Blasting shafts

A blast shaft is a structure set into the street . In West Germany, three blasting shafts, located one behind the other at short intervals, were used. It is less common to work with two or four to six shafts in a row. When building such shafts, care was taken to ensure that the detonation of the cargo would delay the advance of enemy forces as much as possible, but that the neighboring infrastructure , such as the sewer system , would be harmed as little as possible.

The explosion crater of such a blast should create a hole about twice as wide as it is deep. The stipulation was that such a crater should be designed in such a way that a tank could not simply drive through it. Mines should be laid in the crater itself , as well as in the surrounding area, to prevent bypassing.

The "Guidelines for the establishment and maintenance of prepared locks and paralysis" of 1968 prescribe:

"Road and railway interruptions caused by funnel blasting should cover the cross-sections in their total width. [...] The blasting shafts should be distributed along the longitudinal axis in such a way that a web of no more than 7–8 m remains between the funnels. This makes the use of rapid armored bridges and the piercing of the footbridge with bulldozers or clearing armor more difficult. "

The blast shafts had a diameter of about 60 cm and a depth of mostly four to six meters. The lid had a diameter of 92 cm and a weight of about 150 kg. It can be recognized as the cover of a blasting shaft by the retaining screw in the middle.

The depth of the blast shaft, the type of surrounding rock and the desired funnel size played a role in calculating the explosive force. The results obtained from such analyzes were stored in a booklet. The effective rule of thumb was 100 kg per running meter of shaft depth.

The blasting shafts were empty and would not have been loaded with the intended explosive charge until immediately before the detonation. The explosive charges were stored in barricade houses.

Blowing up bridges

There were several possibilities for blowing up bridges. Especially in older bridges there were chambers in the abutments or pillars that could have been filled with explosives in an emergency. Newer bridges were mostly prepared for attaching cutting charges that would only have destroyed the superstructure.

Carrier locking

Carrier locks were mainly used where an explosion would have caused great collateral damage, for example in inner-city areas or at lock systems. They consisted of several rows of about 80 cm deep shafts, which were arranged across the blocking road. The lids were similar to those of the blasting shafts, but were only about 52 cm in diameter. In an emergency, an approximately 2.20 meter long steel girder would have been inserted into each shaft, which would not have been able to be pulled out afterwards. The girders were stored in blocking material stores in the immediate vicinity of the barrier.

Ramp locks were similar to the girder locks, however, no simple steel girders were inserted, but triangular constructions made of steel girders welded together.

Fall body locks

Falling objects were massive concrete bodies that were arranged above or to the side of the traffic route to be blocked. To trigger the lock, its bracket would have been blown away and the concrete body would have fallen onto the traffic route. Such barriers were located at the first three tubes of the New Hamburg Elbe Tunnel .

Foam barriers

Foam barriers were relatively rare. They were only intended to close tunnels. In an emergency, the tunnel would have been flooded with lightweight foam , which would have made it impassable for vehicles and infantry for up to three days.

maintenance

In West Germany, the Wallmasters , who belonged to the Bundeswehr's pioneer troops, were responsible for maintaining the prepared lock and attaching the explosive charges . She worked in civilian clothes for maintenance (at least for systems close to what was then the inner-German border ); her vehicles had civilian paintwork and civilian license plates.

sabotage

In 1952 Walter Zauner from Regensburg was sentenced by a US military court to three and a half years in prison for walling up the blasting chambers of the Mariaorter Bridge. Zauner's story was documented in 1983 in the DEFA film A Pillar in the Stream .

See also

Web links

- Bunkers, bases and relics of the Cold War

- Explosion shaft information at Sperranlagen.de

- Information on various barriers on geschichtsspuren.de (formerly lostplaces.de)

- Anton H. Dorow: Bombs under the manhole cover , in: Frankfurter Neue Presse from December 7, 2012 ( online )

- Information on the Cold War in Schleswig-Holstein and the "Fulda Gap"

- Control of old barriers: from the everyday life of a wall master

Individual evidence

- ↑ a b c d e Michael Grube: Prepared barriers on Germany's roads.

- ↑ “Who was Walter Zauner? “ Retrieved September 30, 2014

- ↑ G. Willen: DEFA films - An inventory p. 126.

- ↑ A pillar in the river At: filmportal.de accessed on July 9, 2017