Tensile-compression-torsion test

The tensile-compression-torsion test (ZDT test) is a test method used to determine the strength perpendicular to the fibers and the shear strength of fiber-plastic composites . When considering the transverse and shear can load are combined, so that the influence of the different types of stress can be determined in the strength. Thin-walled tubular bodies are used as test bodies.

execution

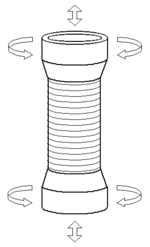

The test specimens are clamped at the thickened ends . The testing machine twists the tubular body, creating a constant state of shear stress in the pipe wall. At the same time, the tubular body can be subjected to axial pressure or tension, whereby the shear stress state transverse pressure or transverse tension is superimposed (the FRP fibers are aligned transversely to the axis of the test body due to the winding ). The strains or loads are recorded using strain gauges or force and torque transducers .

background

In the case of fiber-plastic composites, the tolerable stress state depends on the applied stress combination. Therefore, different combinations of thrust and lateral pull or lateral pressure must be checked. With the ZDT test, the matrix-dominated basic strengths of a UD layer can be determined directly.

In addition to the pure breaking load , the ZDT test can also be used to determine elasticity quantities.

Combined stress drops can practically not be determined with flat tensile specimens or specimens in push frames . With flat specimens there is also the problem of the uneven tension in the clamping. This often causes a failure in the restraint and not in the free area.

Specimen

The test specimens consist of a pure circumferential winding of the fiber-matrix combination to be tested. Thickenings are angled at the ends to make clamping easier. The test specimens can be produced using the wet winding process or from prepreg . Both hot and cold curing resins can be used in the wet winding process . The ZDT test is therefore not limited to a specific matrix or fiber type.

Results

The results of the test are mostly converted to stresses and recorded in space (space of the fiber perpendicular or transverse tensile / compressive stresses and the transverse longitudinal shear stresses). If you interpolate the measuring points, you get a break curve . The maximum tolerable voltage combinations can be read from this.

literature

- Alfred Puck , Helmut Schürmann: The tension / compression torsion test on tubular specimens . In: Kunststoffe , Vol. 72 (1982), pp. 554-561.