Cycloidal gear

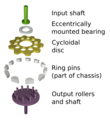

Cycloid gears are eccentric gears . Cam disks transmit torques by rolling, so they do not need gears and are not exposed to any shear forces .

Sudden failures are excluded.

The even load distribution within the gear unit, the high shock absorption and the contact between the cycloid disc and the housing via rollers and ball bearings ensure low-wear operation. This extends the service life compared to other types of gears such as worm gears , the backlash is less and the rigidity is higher. Cycloidal gears are used, for example, as an alternative to worm gears for the servo motor drive of many rotary tables.

An eccentric drives a cam with cam sections ("cams") of the number n , which roll in a fixed pin ring with N = n + 1 pins. The transmission ratio in this case corresponds directly to the number of lobes n . In general, the transmission ratio results from the ratio of the number of cams n and the difference between the number of bolts N and the number of cams n :

The cam disk rolls over the bolts of the bolt ring. The output moves by one curve section for each revolution of the drive wheel. This creates lower speeds against the drive rotation.

The cycloid disk is usually constructed with the aid of a shortened cycloid in order to keep the eccentricity of the disk and the associated unbalance forces low at high speeds.

In addition, these gears are not self-locking . They can also be driven backwards by overcoming a definable breakaway torque.

See also

- Harmonic drive gear (sliding wedge gear, also backlash-free)

Web links

Individual evidence

- ↑ tec-science: How does a cycloid gear work? In: tec-science. January 14, 2019, accessed on November 5, 2019 (German).

- ↑ tec-science: How does a cycloid gear work? In: tec-science. January 14, 2019, accessed on November 5, 2019 (German).

- ↑ Georg Jacobs (Ed.): Maschinengestaltung Volume II. Verlag Mainz, Aachen 2016, ISBN 978-3-86130-749-5 , p. 247 f.