Chemical pulp

As dissolving pulp (English dissolving pulp ) is highly pure cellulose mostly from designated timber by the sulphate or sulphite is obtained. Chemical pulp is used as the starting material for cellulose deformation and derivatization. Chemical pulp is also the starting material for the production of regenerated cellulose from which fibers such as viscose and foils such as cellophane are made.

The difference between chemical pulp and pulp , e.g. B. for paper production , is the higher purity or the higher proportion of cellulose. This is for use e.g. B. in chemical processes, necessary.

Manufacturing

Chemical pulp is mainly obtained from raw materials rich in cellulose using chemical processes. But also the biotechnological production, z. B. from acetic acid by fermentation of certain bacteria is possible.

Chemical process

Wood ( wood pulp ) and various annual fiber plants can be used as raw materials for chemical pulp production . Around 10% is also obtained from the linters of cotton ( cotton fiber ).

About 60% of the annual production is made according to the sulphite process, while the pre-hydrolysis Kraft process is increasingly being used. These chemical processes are also used for pulping pulp for the paper industry , but there are often other thermal and / or mechanical wood pulping processes that deliver a higher yield but an inferior product or fiber quality.

Biotechnological process

Chemical pulp or cellulose can be produced aerobically by fermentation (with the addition of oxygen) by acetic acid- producing bacteria such as Acetobacter xylinum and Gluconacetobacter xylinus . This cellulose, known as bacterial cellulose, is characterized by high purity, a high degree of crystallization and polymerisation and a very fine fiber structure. Due to the expensive manufacturing process, bacterial cellulose is currently not suitable for large-scale use as a polymer material.

Quality requirements

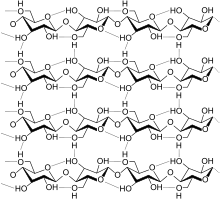

High demands are placed on the quality of chemical pulp. The α-cellulose content should be at least 90% and the proportion of accompanying substances such as hemicelluloses , lignin , extract substances and metal ions as well as carbonyl and carboxy groups should be as low as possible. In addition, degrees of whiteness of 88 to 95% are required, which are significantly higher than with paper pulps. The content of α-cellulose for the production of cellulose acetate should be 96-99%, while for viscose products a content of 91 to 92% is sufficient, since short-chain polysaccharides are removed in an additional cleaning step in the viscose process . A particularly high level of purity and high viscosity can be achieved with cotton linters as raw material, since they already have a high cellulose content of over 80% in their natural state and can be digested using the soda process with comparatively little effort .

Economical meaning

The worldwide production of chemical pulp in 2001 was around 3.2 million t, which corresponds to a share of only 2% of the total pulp production. In 2005, around 320,000 t of chemical pulp were processed into approx. 190,000 t of regenerated cellulose and 130,000 t of cellulose derivatives in Germany . The worldwide production of cellulose regenerates and derivatives of approx. 5 million t is divided into 65% regenerates and 35% derivatives.

Chemical pulp products

Cellulose-based polymer materials are made from chemical pulp and are divided into two main groups: cellulose derivatives and regenerates. The derivatives are further divided into cellulose ethers and cellulose esters, while various fibers and films are produced from regenerated materials. Materials based on chemical pulp were among the first polymer materials to be developed and have recently been marketed specifically as biopolymers due to their natural origin and their partial degradability, as opposed to petrochemical polymers .

Cellulose derivatives

- Cellulose ethers : additives for viscosity stabilization or as water binders in building materials , adhesives , cosmetics , detergents , paints or in the paper industry

- Cellulose esters : Thermoplastic plastics such as cellulose nitrate ( celluloid ), cellulose acetate , cellulose propionate and cellulose butyrate

Regenerated cellulose

- Fibers:

- Foils:

- Cellulose hydrate (cellophane)

Individual evidence

- ↑ S. Müller: Possibilities of using liquid ammonia in the production and activation of chemical pulp , dissertation, University of Stuttgart, Institute for Textile and Fiber Chemistry, 2004. pdf .

- ↑ L. Carraro: Accessibility of chemical pulp and reaction behavior with carboxymethylation , dissertation, Eidgenössische Technische Hochschule Zürich, 2005. pdf .

- ↑ a b c Lenzing AG: Chemical pulp is pure cellulose: a "high performance polymer" for materials and fine chemicals ( page no longer available , search in web archives ) Info: The link was automatically marked as defective. Please check the link according to the instructions and then remove this notice. .

- ↑ a b c d H.-J. Endres and A. Siebert-Raths: Technical biopolymers - framework conditions, market situation, production, structure and properties , Carl Hanser Verlag, Munich 2009, p. 136, ISBN 978-3-446-41683-3 .

- ↑ Z. Gromet-Elhanan and S. Hestrin: Synthesis of cellulose by Acetobacter xylinum. VI. Growth on citric acid cycle intermediates. In: Journal of Bacteriology. 85 (2), 1963, pp. 284-292.

- ↑ Bacterial cellulose on material archive. ch, accessed on March 21, 2017.

- ^ I. Claus: Suitability of the MEA process for the production of chemical and paper pulps , dissertation, University of Hamburg, 2005. pdf .

- ↑ Agency for Renewable Raw Materials (FNR) e. V. (Ed.): Renewable raw materials in industry pdf .