laundry detergent

The collective term detergent refers to mixtures of different substances in liquid , gel-like or powder form, which are used to clean textiles . In addition to powder and liquid detergents, ready-to-use detergents have also become established in recent years, which essentially consist of liquid detergents in so-called tabs. They all contain washing-active substances which, in combination with the exposure time, the temperature of the washing liquor and the mechanical processing of the textiles, are able to dissolve various types of contamination.

history

From antiquity to the middle of the 20th century

The beginning of washing probably only consisted of the use of the washing effect of the pure water , which was intensified by rubbing, hitting and kicking the laundry. In the Odyssey , Homer describes how Nausicaa and her playmates wash their clothes on the beach and place them in the sun to bleach.

In ancient Rome was a first type of detergent to use. Urine was collected , fermented to form ammonia and washed with it.

The Sumerians are considered to be the oldest civilized people who know how to make a soap-like substance from wood ash and oil . Cuneiform records tell of the weaving , fulling and washing of woolen fabrics. There is a detailed recipe handed down, in what proportions wood ash and oil must be mixed. This is also the first record of chemical reactions .

Also from the Egyptians , Gauls and Teutons is saponification of fats and oils known. However, such soaps are more likely to have been used in cosmetics and as medicinal products. It was not until the Greco-Roman doctor Galenos (130–200 AD) drew attention to the cleaning effect of soap .

Further reports on soap and its use are rare. Charlemagne (747–814 AD) promoted the soap boiler craft in the Frankish Empire . The Arabs, Spaniards, Italians and French brought the soap industry to its heyday, as the olive tree was discovered as a source of raw materials. From the 14th century there were soap boiler guilds in Germany . But the soap was still a luxury item. Only the discovery of the technical production ( Leblanc process and Solvay process ) of soda , which is required for the saponification of fats, made soap cheaper.

At the beginning of the 20th century, soap was increasingly used in “automatic” detergents in combination with other components. In addition to the soap they contained builders ( builders ), notably soda ( sodium carbonate ), water glass (sodium silicate) and sodium . These substances saved the laborious task of bleaching the lawn . The brand name Persil by the Henkel company , introduced in 1907, documents this with its name: Per von Perborat and Sil von Silikat.

As early as 1914, the chemist Otto Röhm brought the special detergent "Burnus" with contained pancreatic enzymes onto the market. Protein-bound soiling settles on the laundry at higher washing temperatures and can only be removed by intensive rubbing. The treatment with protein-dissolving enzymes replaces the intensive mechanical processing of the laundry, washing the laundry was no longer so exhausting, the clothing was no longer worn out as quickly and the stains also loosened in cold water, which helped save fuel and soap.

From the 1960s onwards, there was an increasing switch from hand washing to machine washing . This also made it necessary to change the detergent composition. Among other things, the water hardness sensitivity had to be improved. Because the formation of lime soaps , compounds of soap with alkaline earth metals , reduces the washing power, makes the laundry hard and makes it wear out faster.

Gradually, the raw materials from which the soaps were made also changed. In Germany, tallow was the fat base for a long time , later palm oil and coconut oil were added (see oleochemistry ). Over time, however, the products were made more and more on the basis of coal and petroleum . Turkish red oils were a forerunner . In 1834 the chemist Friedlieb Ferdinand Runge produced a "sulfonated oil" from sulfuric acid and olive oil, which was first used in the printing press . A manufacturer from Scotland bought the process and applied it using the cheaper castor oil there. This produced a sulpho-ricin oleate , which had a very good wetting effect and was particularly used in cotton dyeing . Even if this chemical was not used for cleaning, the use of the sulfo group instead of the carboxy group , which is sensitive to water hardness, was recognized.

Development of modern detergents from the 1930s

The name surfactants for surface-active substances was proposed in 1964 by the chemist Götte, who worked for the Henkel company.

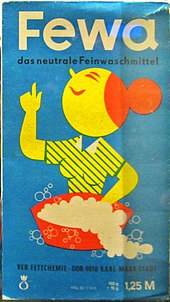

In 1932, the chemist Heinrich Gottlob Bertsch , who came from Württemberg, invented the first mild detergent with the name Fewa at Chemnitz-based H. Th. Böhme AG , which was also the first fully synthetic detergent in the world. Because the product was so extremely successful, three new plants had to be put into operation in Chemnitz by 1938. As early as 1935 the product was outsourced to the Chemnitz company Böhme-Fettchemie GmbH and from then on belonged to the Henkel Group .

In the 1950s, classic soap was increasingly replaced by tetrapropylene benzene sulfonate (TPS), which was produced on a petrochemical basis. This led to foam formation and a lack of oxygen in the waters, since TPS was only insufficiently degradable. This effect was intensified by the spread of washing machines in households and by the fact that it became uncommon to give laundry to large laundries. A general overdose was the result. For this reason, biodegradability soon came to the fore as a new criterion.

On September 5, 1961, the Detergents Act was passed; It came into force at the end of 1964. This includes the December 1, 1962 Detergent Ordinance. From October 1, 1964, detergents and cleaning agents should only contain surfactants that are at least 80% biodegradable. More and more linear alkylbenzenesulfonates (e.g. sodium dodecylbenzenesulfonate ) have been used instead of the branched TPS, which is difficult to break down .

In order to support surfactants in their effect, mainly pentasodium triphosphate was used for water softening . From the 1980s, inorganic ion exchangers , such as zeolite A , which prevent overfertilization of water with phosphates , became important. They were invented by Milan Schwuger and Heinz-Gerd Smolka at Henkel in 1972 and the first phosphate-free detergents with zeolite A came onto the market in 1977. Other substances were added that improved the washing effect.

With the first version of the Washing and Cleaning Agent Act (WRMG) from 1987, the European Detergent Ordinance from 2005 and the new version of the WRMG from 2007, the requirements for the biodegradability of surfactants were further increased. The proportion of petrochemically produced surfactants decreased and the proportion of oleochemically produced surfactants from renewable raw materials increased to 50%.

Timeline (20th century)

- In 1907, the first modern detergent was named in Germany Persil from Henkel produces. The name was made up of sodium PER borate and SIL ikat.

- In 1932, Heinrich Bertsch in Chemnitz developed the world's first fully synthetic detergent called Fewa .

- In 1960, easily biodegradable surfactants were introduced to reduce the build-up of foam in rivers and weirs .

- In 1968 the widespread use of enzymes in detergents began. These ensure the faster breakdown of protein , fat and starch .

- 1986 new phosphate- free detergents (developed in 1972) relieved the over-fertilized waters .

- Color detergents for colored laundry were introduced in 1992 . These contain no bleach and reduce the transfer of color between the individual items of laundry.

- In 1994, new super-concentrate detergents came onto the market, of which only half the usual dosage was needed. In this way, the waters are protected from excessive amounts of filler salts .

species

Different types of detergents are differentiated according to ingredients and the range of possible washing temperatures:

- Heavy-duty detergents (also known as universal detergents or high- temperature detergents ) are suitable for all temperature ranges (20 ° C to 95 ° C), most textiles and washing processes.

- Colored detergents (also called colored detergents ), for washing temperatures of 20 ° C to 60 ° C, do not contain bleach.

- Delicates detergents are suitable for a washing temperature of 30 ° C and for hand washing. They do not contain bleach or optical brighteners , but instead contain more enzymes and soap . Higher temperatures destroy the contained enzymes.

- Special detergents for wool , silk , down , sports and membrane textiles are generally suitable for low temperatures.

- Modular detergents consist of the individual components of a heavy-duty detergent, which can be dosed individually.

Care label for textiles

The garments differ in the type of fibers (polyamide, polyester, polyacrylic, polyurethane, wool, cotton, linen, silk) and in the type of dyeing of the textile fiber (the dye can be linked to the fiber ionically or through a chemical bond) . Therefore, both the temperature and the cleaning agent used are of considerable importance for every washing process. Natural wool or silk in particular can usually only be cleaned by hand washing. Since 1961, textile labels with information on washing and care treatment have been sewn into every item of laundry. The washing tub with the number in the middle stands for the maximum usable temperature in degrees Celsius during the washing process. This temperature should not be exceeded during the washing process. A small bar under the wash tub indicates the gentle cycle.

General ingredients of detergents

All detergents contain the following components:

- Surfactants are the main active ingredient in detergents. Depending on the detergent, they make up around 20 to 30%. Are used anionic (eg. As linear alkyl benzene sulfonates (LAS), secondary alkanesulfonates (SAS), fatty alcohol sulfates (FAS), and methyl ester sulfonates (MES)) and non-ionic surfactants (eg. As fatty alcohol polyglycol ethers (FAE) and sugar surfactants ).

- Water softeners create soft water. Lime soaps no longer form with today's surfactants , but the calcium and magnesium salts that are formed during drying damage the textile structures. Zeolite A (water-insoluble, powder detergent) and also sheet silicates (water-insoluble, powder detergent) and citrates (water-soluble, liquid detergent) are used as water softeners . So-called builders (among other functions) support these mineral softeners. Water softeners prevent limescale build-up in the washing machine. Additional water softeners are not required when using conventional detergents. However, the water softeners are crucial for the secondary washing performance (prevention of graying) and therefore belong to the active washing substances.

- Washing alkalis increase the pH value of the washing liquor. This causes the fibers to swell and the dirt can be removed more easily.

- Enzymes , e.g. B. for the removal of protein, starch and fat stains. They work differently at low and / or medium washing temperatures and are destroyed ( denatured ) at high temperatures . ( Amylases break down starch , lipases break down fats , proteases break down proteins and cellulases break down cellulose to reduce the roughness of cotton textiles.)

- Dirt carriers keep the detached dirt in suspension and prevent it from being deposited on the laundry again. → Carboxymethyl cellulose coated cotton fibers against dirt.

- Core soaps and silicones regulate as defoamers , the development of foam .

- Fragrances mask the wearer's own odor.

- Thickening agents or trickle salts such as. B. Sodium sulfate keep powder detergents in powder form during storage and serve as an inexpensive extender . Detergents called concentrate contain less diluent. The active ingredients are less diluted.

Heavy duty detergent

Heavy duty detergents (also universal detergents or cooking detergents ) are mostly powder detergents for textiles . They are suitable for all temperature ranges (20 ° C to 95 ° C), most textiles and washing processes. Heavy- duty detergents are becoming less important in favor of colored detergents . The amount of heavy-duty detergent required for washing is determined not only by the degree of soiling of the laundry but also by the hardness of the water . In areas with very low water hardness, the water softener is inevitably used, in those with high hardness the other ingredients are overdosed , see the section on modular detergents .

Additional ingredients

- Bleaching agents remove colored dirt that cannot be washed out, e.g. B. from fruits or blood. There are bleaches based on hydrogen peroxide , such as. B. sodium perborate . They work particularly well at high washing temperatures and are found in powder detergents. It has not yet been incorporated into liquid systems, since the bleach in a dissolved state would inactivate the enzymes.

- Bleach activators increase the effectiveness of bleaches at low temperatures. This may relate N -Acetylverbindungen used with peroxides anions of peracetic acid form, which then act as the actual bleach. As N -Acetylverbindung substantially is tetraacetylethylenediamine (TAED) is used.

- Optical brighteners are fluorescent substances that make white appear whiter. In the case of colored textiles, the brighteners can change the color impression . Optical brighteners are often found in liquid detergents to compensate for the lack of bleaching effect.

- Bleach stabilizers prevent the uncontrolled decomposition of the bleach during storage and when the detergent is used. Omnipresent traces of heavy metals promote the rapid release of oxygen. Phosphonates can bind the heavy metals.

- Preservatives are not necessary for powder detergents, as microbacterial infestation hardly occurs due to a lack of water.

Ingredients of heavy duty liquid detergents

In addition to the ingredients listed above, additional substances are used in liquid heavy-duty detergents.

- Alcohols strengthen substances that have a cleaning effect and, in the case of liquid detergents, enable the surfactants to be dissolved; sometimes they also act as preservatives .

- Preservatives protect detergents from microbial attack.

- Water softeners that are soluble in liquid detergent. → Complexing agents such as B. NTA , phosphonates , EDTA , no mineral softeners.

Colored detergent

Colored detergents are powder or liquid detergents for textiles . They are mostly suitable for the temperature range from 20 ° C to 60 ° C and for most textiles and washing processes. Color detergents should prevent the mutual discoloration of textiles. With poorly colored textiles, however, there is still the possibility of discoloration. Certain polymers, iron and manganese complexes and enzymes in color detergents prevent the transfer of dyes.

Colored detergents have gained market share compared to heavy-duty detergents . In 2004 the market share was already 28% and in 2008 in Germany it was 33% in terms of value.

ingredients

In addition to the normal ingredients of a detergent, colored detergents contain:

- Color transfer inhibitors to protect the color of textiles. You avoid the color of color on other textiles during the washing process.

In contrast to heavy-duty detergents, the following substances are usually not present in colored detergents:

- Bleaches , bleach activators , bleach stabilizers

- Optical brighteners . In the case of colored textiles, the brighteners can change the color impression .

Mild detergent

Detergents for delicate fabrics, unlike heavy-duty detergents, do not contain any brighteners or bleaching agents . Some mild detergent effect without enzymes (such as cellulase ), and are useful in textiles consisting of cellulose consist fibers or include these, such as cotton , viscose or lyocell . In a test by Stiftung Warentest, the use of special mild detergents for black or dark clothing did not bring any advantage over conventional mild detergents or colored detergents.

Wool detergent

Detergents that are suitable for washing wool or silk are often declared as wool detergents. They are pH-neutral and contain neither bleach nor proteases , which attack the wool and silk fibers. The ingredients counteract the felting of wool, and some of them also contain substances that make wool fluffier and softer.

Modular detergent

Modular detergents usually consist of three essential components of a heavy-duty detergent, the components are offered individually in a bag or box .

- The softener ensures the adaptation to the respective local water hardness.

- The basic detergent without bleach corresponds to a mild detergent and is dosed according to the degree of soiling of the laundry.

- The bleach (or also: stain remover) is only added in the case of heavy soiling and laundry that can be bleached. It turns the basic powder into a heavy-duty washing powder.

- These agents are supplemented by special stain removers that are available separately, which are usually used before the washing process and partly work on the basis of enzymes added to normal detergents - if allergy sufferers cannot tolerate them, they can therefore be omitted from a modular system.

The advantage of a modular detergent is - as with other modular systems - that it is more adaptable, specifically in the need-based dosage: heavy-duty detergents have to be dosed higher with hard water in order to provide more softener. In doing so, the environmentally harmful washing-active substances are inevitably dosed higher, without this being necessary for the cleaning performance. Modular detergents are more environmentally friendly here, as the water softener can be dosed higher independently of the basic detergent.

In view of the fact that the vast majority of laundry today only consists of lightly soiled laundry, stain remover is only added to heavily soiled laundry (such as baby laundry or clothing in 'dirty professions').

Detergent for certain water hardnesses

Since 2013 there has also been washing powder that has been specifically designed for the three hardness ranges. Here - similar to modular systems - only as much softener and detergent is dosed as the local hardness of the water requires.

Washing / fabric softener combinations

Some powder detergents contain substances that are supposed to soften the laundry in the final rinse so that an additional fabric softener is not necessary. The advantage is that no separate agent has to be bought and dosed. The disadvantage is that the softening effect always occurs - even where it is not wanted, e.g. B. with collars or cuffs of shirts or curtain fabrics.

Tandem system

The targeted use of compact heavy-duty detergents in combination with compact colored detergents is sometimes referred to as a tandem system. The compact heavy-duty detergent powder is used for white laundry and at high temperatures, the compact colored laundry detergent for colored laundry. In general, these powder detergents do not contain sodium sulfate as an additive . According to the Federal Environment Agency, the environmental compatibility of compact colored detergents is as good as that of modular detergents .

Functional detergent

Functional detergents are used to clean, maintain, impregnate and maintain the value of a wide variety of technical fibers. They are mainly used for the care of sports textiles and should help to increase the service life of functional textiles. Functional detergents are available for textile membranes, microfibres, down fillings and as a hygiene rinse for functional underwear.

Controversy

Market dominance

The detergent market in Europe was dominated from 2002 to 2005 by a detergent cartel in which the three European market leaders Procter & Gamble (sells Ariel, Lenor, Dash and Vizir), Unilever (sells Coral and Skip) and Henkel (sells Persil, Weißer Riese, Spee and Terra) had made agreements on prices and market shares. Henkel reported this to the German Cartel Office in 2008 . The EU Commission fined Procter & Gamble to 211.2 million euros and Unilever to 104 million euros.

environmental Protection

After use, all cleaning agents end up in sewage treatment plants and rivers, where they cause costs or environmental damage. Phosphates are not separated in all sewage treatment plants, not all surfactants are 100% biodegraded.

When it comes to the dosage of detergents, too little is often given to the amount and degree of soiling of the textiles to be washed. The dosage is left to the consumer, although it would be technically possible to let the washing machines do this. Unclear instructions, different concentrations of active ingredients in different products and a lack of standardization on the part of the manufacturer or ignorance of the hardness of the water and deliberate additional additions on the part of the consumer often lead to ineffective overdoses. In many cases, the "recommendations" of the detergent suppliers are blindly trusted. Their interests (increased sales through predetermined “quasi-prescribed” quantities) stand in contrast to the necessities of environmental protection.

On the other hand, the informed consumer has simple measures available to reduce the chemical input into the environment by up to 60%, e.g. B. by using a modular system (as described above) as a detergent.

When buying detergents, you can pay attention to the EU Ecolabel and Blue Angel labels . Products with one of these labels are free from microplastics . On softener should generally be avoided.

Remaining detergent residues in clothing

Detergents are not completely washed out of clothes (see also under washing machine ). This mainly applies to people with an allergic reaction, but must also be observed for kitchen textiles ( swirl towels, towels to be cooked with for cooking napkin dumplings , etc.).

Detergent residues in house dust

Linear alkylbenzenesulfonates as components of detergents are quantitatively one of the most important pollutants in house dust . In 2004 they were found in an investigation by the Austrian Federal Environment Agency in amounts between 37 and 660 milligrams per kilogram of house dust.

Detergent residue in the washing machine

Due to the low washing temperature and the low water consumption of modern washing machines, detergent residues can easily accumulate in the machine and form a breeding ground for germs. Washing machine manufacturers therefore recommend a wash cycle at maximum temperature and without laundry at regular intervals.

See also

literature

Older literature

- W. Kling: Physics and chemistry of washing . In: Angewandte Chemie , 62 (13/14), 1950, pp. 305-311, ISSN 1521-3757

- A. von Segesser: Soap, detergents and syndets . Article in the Neue Zürcher Zeitung from June 11, 1952

- HG Hauthal: Modern detergents . In: Chemistry in our time , 26th year. No. 6, 1992, pp. 293-303, ISSN 0009-2851

Current literature

- Herrmann G. Hauthal, Günter Wagner: Cleaning and care products in the household. Chemistry, application, ecology and consumer safety . 2nd Edition. Verlag für Chemische Industrie Ziolkowsky, Augsburg 2007, ISBN 978-3-87846-265-1 .

- Herbert Sommerfeld, Klaus-Peter Berndt, Erich Schäfer (Eds.): Chemicals in the household. Detergents and cleaning agents, cosmetics, paints, pesticides and insecticides, adhesives, packaging . (= Study materials of the advanced course "Environmental Protection for Education and Housekeeping" ). University of Potsdam / Otto von Guericke University Magdeburg , 1993, ISBN 3-929757-14-1

- Günter Wagner: Detergents: Chemistry, Environment, Sustainability . 4th, completely revised and expanded edition. Wiley-VCH, Weinheim 2010, ISBN 978-3-527-32678-5

- Michaela Wilke: detergent. From soap to ready-made powder . In: Naturwissenschaftliche Rundschau , 10, 57, 2004, pp. 544–555, ISSN 0028-1050

Web links

- Detergents and cleaning agents (UmweltWissen - Bavarian State Office for the Environment; PDF; 184 kB)

- Background information on the Detergent and Cleaning Agent Act ( Memento from November 5, 2013 in the Internet Archive )

- Detergent and Cleaning Agents Act in full text ( Memento of December 7, 2008 in the Internet Archive )

- ÖkoRein - database for environmentally and health-friendly detergents and cleaning agents

Individual evidence

- ↑ Genetic engineering and enzyme technology ( Memento from June 6, 2014 in the Internet Archive ) (PDF; 3.9 MB)

- ↑ Corporate history of the Burnus Group

- ↑ Burnus - The enzyme-based detergent at evonik.de

- ↑ Can you wash, Johanna? In: sz-online.de. May 8, 2003, accessed August 4, 2015 .

- ↑ Law on detergents in detergents and cleaning agents ( Federal Law Gazette I p. 1653 )

- ↑ Molecular enzyme technology: environmentally friendly biosurfactants . March 11, 2010, accessed April 6, 2010

- ↑ a b Agency for Renewable Raw Materials e. V. (FNR): Market study renewable raw materials . Gülzow 2006, as a PDF file

- ↑ ABC of German inventions . Report by Dorothee Ott and Kristine von Soden. Hessischer Rundfunk , December 23, 2010

- ↑ B. Fabry: Tenside. In: Chemistry in Our Time. 25th year 1991, No. 4, p. 214, ISSN 0009-2851

- ↑ uni-paderborn.de: The Softening of Water ( Memento from April 16, 2013 in the Internet Archive ), accessed on April 4, 2013

- ↑ test 02/2012, detergent: powder is better . Investigation by Stiftung Warentest , accessed on December 11, 2012

- ↑ FP Lang: New color care additives for detergents . In: SÖFW-Journal 131, No. 10, 2005, p. 28

- ^ Günter Wagner: detergent . 4th, revised. Edition. John Wiley & Sons, 2011, ISBN 978-3-527-63540-5 , p. 179

- ↑ Detergents - fine detergents on hauswirtschaft.info, accessed on March 21, 2013

- ↑ Detergent for the dark: Too much black magic . In Test.de , March 29, 2001

- ↑ Liquid detergents 19 detergents put to the test - product knowledge - the differences. Stiftung Warentest, February 8, 2013, accessed on June 7, 2020 .

- ↑ Washing clothes: use the right detergent and unnecessary products. Consumer advice center, February 6, 2019, accessed June 7, 2020 .

- ↑ EU imposes million fine on detergent cartel . In Tagesschau online , April 13, 2011, accessed on April 13, 2011

- ↑ Ecological washing . Accessed January 21, 2012

- ↑ Washing in an environmentally friendly way Liquid detergents often contain microplastics. In: rnz.de . June 5, 2019, accessed June 9, 2019 .

- ↑ M. Uhl, P. Hohenblum, S. Scharf, C. Trimbacher: House dust - an indicator for indoor pollution . (PDF; 2.7 MB). Federal Environment Agency, Vienna 2004, p. 6

- ^ Second German television (ZDF): Stinkende Waschmaschinen - WISO - ZDFmediathek - ZDF Mediathek. (No longer available online.) In: www.zdf.de. Archived from the original on January 6, 2017 ; Retrieved August 3, 2016 .