sodium

| Structural formula | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

||||||||||||||||||||||

| General | ||||||||||||||||||||||

| Surname | Sodium carbonate (anhydrous) | |||||||||||||||||||||

| other names | ||||||||||||||||||||||

| Molecular formula | Na 2 CO 3 | |||||||||||||||||||||

| Brief description |

colorless crystalline powder |

|||||||||||||||||||||

| External identifiers / databases | ||||||||||||||||||||||

|

||||||||||||||||||||||

| properties | ||||||||||||||||||||||

| Molar mass | 105.99 g mol −1 | |||||||||||||||||||||

| Physical state |

firmly |

|||||||||||||||||||||

| density |

|

|||||||||||||||||||||

| Melting point |

854 ° C |

|||||||||||||||||||||

| boiling point |

1600 ° C (decomposition) |

|||||||||||||||||||||

| solubility |

good in water (217 g l −1 at 20 ° C) |

|||||||||||||||||||||

| safety instructions | ||||||||||||||||||||||

|

||||||||||||||||||||||

| Toxicological data | ||||||||||||||||||||||

| Thermodynamic properties | ||||||||||||||||||||||

| ΔH f 0 |

−1130.7 kJ / mol |

|||||||||||||||||||||

| As far as possible and customary, SI units are used. Unless otherwise noted, the data given apply to standard conditions . | ||||||||||||||||||||||

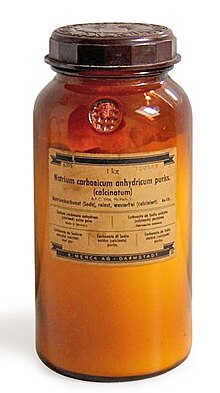

Sodium carbonate (technical language; standard language sodium carbonate ) Na 2 CO 3 , anhydrous also called calcined soda , pure soda or washing soda , is a salt of carbonic acid . As a food additive , it has the abbreviation E 500i .

Occurrence

It comes as a mineral Natrit in soda lakes in Egypt , the Turkey ( Lake Van ), East Africa (z. B. Lake Natron and other lakes of the East African Rift ), California , Mexico and as trona (Na (HCO 3 ) · Na 2 CO 3 · 2H 2 O) in Wyoming ( USA ), Mexico, East Africa and in the southern Sahara .

Anhydrous sodium carbonate takes Natrokarbonatit -Vulkanen (eg. As the Ol Doinyo Lengai ) as a mineral Gregoryit in igneous before, but is transformed on contact with rain water very quickly to soda to.

History of Soda Making

Initially, natural soda was extracted from minerals in salt lakes, for example, the best known in Egypt 4000 years ago as baking soda as a mixture of sodium carbonate and sodium hydrogen carbonate , which was used to produce glass. Later on, soda (also known as ash salt) was obtained by cremating dried plants from salt steppes or from the beach (with a particularly high sodium content), especially in the Mediterranean region. The procedure was similar to that for potash from land plants, but in the case of potash it contained predominantly potassium. Some of the best varieties came from Alicante and were called Barilla, which was later generally carried over to plant soda.

The development of artificial soda, especially for soap production, began with Henri Louis Duhamel du Monceau's analytical differentiation between soda and potash around 1730. He also showed that in principle soda could be made from table salt. However, table salt was too expensive as a raw material and taxed too high. Further research was carried out into a suitable manufacturing process. Duhamel already made Glauber's salt (sodium sulfate) and showed that it can be used to make soda. The method was improved by Andreas Sigismund Marggraf in Berlin. In 1772, Karl Wilhelm Scheele produced soda by heating brine with lead oxide in small quantities, which was also used by some manufacturers. In 1775, a French Academy of Sciences award for soda production was awarded to encourage preoccupation with the problem (it was never paid). In 1777 Joseph François Malherbe used Glauber's salt industrially in France to make soda. Jean-Antoine Chaptal produced according to the process in Montpellier (after 1780) and PL Athénas in Javier near Paris. In 1789, Jean-Claude Delamétherie suggested glowing Glauber's salt with charcoal, treating the result with acetic acid and using it to glow soda, which, although impractical, had a stimulating effect on the doctor Nicolas Leblanc , who had been working on it for several years. The actual breakthrough came in 1789 with the Leblanc process . In 1791 he opened a factory on behalf of the Duke of Orléans , but he was deprived of the fruits of his discovery by the French Revolution (he committed impoverished suicide in 1806). Since he had teamed up with the Duke of Orléans, the process was expropriated with him, the factory was closed in 1794 and the process was made available free of charge. In 1806 a soda factory was built near Paris based on the process and in the 19th century many other factories were built using the process in France, Germany ( Hermania in Schönebeck near Magdeburg in 1843 and soon afterwards the Rhenania chemical factory in Aachen ) and England. The factories not only supplied soda, but also hydrochloric acid, alkali metals, and chlorine. In the second half of the 19th century it was replaced by the Solvay process developed in 1860 .

Extraction and manufacture

- By breaking down naturally occurring minerals containing sodium carbonate (see above): Because of their various impurities, the starting minerals are recrystallized before transport and further use and then converted into purified, water-free soda (e.g. using the Trona process , named after the starting mineral of the same name) .

- According to the Leblanc process (since 1791): Technical sodium chloride is reacted with hot sulfuric acid to form hydrogen chloride gas and sodium sulfate , which remains as a "salt cake" and in the next step reacts with calcium carbonate and carbon to form sodium carbonate, carbon dioxide and calcium sulfide. After this process for the production of sodium carbonate was replaced by the Solvay process , it is no longer used today, but is still of great historical importance, since it was the beginning of the development of large-scale chemical industry .

- According to the Solvay process (also ammonia-soda process, since 1863): Introducing ammonia and carbon dioxide into a saturated sodium chloride solution and heating the resulting sodium hydrogen carbonate in a rotary kiln .

- The resulting carbon dioxide and the ammonia from the reaction of the ammonium chloride with calcium oxide or calcium hydroxide are fed back into the process, which made it very economical (and thus one of the first chemical cycle processes practiced on a large scale).

- Introduction of carbon dioxide into caustic soda (technically insignificant):

properties

Modifications and hydrates

Sodium carbonate is polymorphic , i.e. it crystallizes in different crystal structures depending on pressure and temperature with the same chemical composition . There are also hydrates that contain crystal water.

- Anhydrous, Na 2 CO 3

- Known as mineral Natrit or under the name pure or soda ash , white substance with a melting point of 854 ° C and a density of 2.51 g / cm 3 . Forms at temperatures above 107 ° C.

- Monohydrate, Na 2 CO 3 .H 2 O

- Known as the mineral thermonatrite , it is formed from the heptahydrate at temperatures> 35.4 ° C.

- Heptahydrate, Na 2 CO 3 · 7 H 2 O

- Forms from the decahydrate at temperatures above 32.5 ° C.

- Decahydrate, Na 2 CO 3 · 10 H 2 O

- Known as mineral soda or known as crystal soda , it crystallizes out from saturated sodium carbonate solutions at below 32.5 ° C (density 1.45 g / cm 3 ).

In addition, sodium carbonate is found in nature together with sodium hydrogen or calcium carbonate in the following minerals:

- Dihydrate, Na 2 Ca (CO 3 ) 2 · 2 H 2 O

- Known as the mineral pirssonite .

- Pentahydrate, Na 2 Ca (CO 3 ) 2 · 5 H 2 O

- Known as the mineral gaylussite or under the name natrocalcite .

- Bicarbonate, Na (HCO 3 ) • Na 2 CO 3 • 2 H 2 O

- Known as the Mineral Trona .

Chemical properties

As the sodium salt of weak carbonic acid, it reacts with stronger acids to form carbon dioxide (foaming). Sodium carbonate dissolves in water with the development of heat ( heat of hydration ). A strongly alkaline solution is created because the carbonate anion reacts as a base with a proton from the dissociation equilibrium of the solvent water to form hydrogen carbonate ion (HCO 3 - ) and a correspondingly high concentration of hydroxide ions is created:

- Dissociation equilibrium of the carbonate ion in water.

Before larger quantities of sodium hydroxide were available , sodium carbonate was the most important base because dissolved in water it behaves like a mixture of sodium hydrogen carbonate and sodium hydroxide: A solution of 50 g sodium carbonate per liter of water has a pH value of 11.5.

- Reaction of sodium carbonate and water.

The standard enthalpy of formation of sodium carbonate is Δ f H 0 298 = −1131.7 kJ mol −1 , the standard free enthalpy of formation ΔG 0 298 = −1048.4 kJ mol −1 , and the standard molar entropy S 0 298 = 136.1 J K −1 mol −1 .

storage

Crystalline soda must be tightly closed or stored in damp rooms, as it releases crystal water in dry air and disintegrates into a white powder.

Conversely, one must calcined, i.e. H. Store water-free soda in dry rooms, as it easily absorbs moisture from the air without immediately looking damp and with it passes into the monohydrate Na 2 CO 3 · H 2 O ( hygroscopy ).

use

Sodium carbonate has been used by humans for a long time. Even the ancient Egyptians used it for mummification ("Nitron"). It has also been used as a cleaning agent and in glass production since ancient times. Today, sodium carbonate is used by almost all branches of industry, making it one of the most versatile chemical products.

Sodium carbonates are used in the food industry as a leavening agent , acidity regulator or carrier employed, for example in baking powder . They are generally approved in the EU as food additive with the number E 500 without maximum quantity restriction ( quantum satis ) for all foodstuffs and may also be added to organically produced food according to the EC organic regulation .

Around 39 million tons of soda were produced worldwide in 1997 . In Germany, the market volume in 1999 was around 2.4 million tons. The largest proportion of soda is consumed by the following five industrial sectors:

- The glass industry uses soda as a raw material for its glass melts, making it the largest consumer of soda. Soda acts as a flux that prevents it from crystallizing in the solidifying glass melt and thus keeps the glass amorphous . The proportion of soda determines the flowability of the melt.

- The chemical industry uses soda for the production of bleaches , borax , chromates such as sodium chromate and sodium dichromate , paints , fillers , tannery aids , industrial cleaners , cryolite , glue and adhesives , metal carbonates , sodium nitrate , perborate , sodium phosphates such as pentasodium triphosphate , silicates (water glasses) such as for example sodium metasilicate pentahydrate and sodium orthosilicate , sulfite , ultramarine paints , water glass and the like. a. Chemicals one.

- In the iron and steel industry soda is used for the desulphurisation of pig iron, cast iron and steel, as well as flotation and flux used.

- In the detergent and soap industry , coarse detergents and other cleaning agents are produced with soda , and fats are saponified . Earlier soda was for this purpose causticized , d. H. reacted with calcium oxide or hydroxide to form caustic soda .

- In the paper and pulp industry , soda is used for digestion, neutralization, cleaning and bleaching as well as for processing waste paper .

- Other uses:

- Leather industry

- Water purification

- Internal feed water treatment in steam boilers

- Bakery production

- Ceramic and enamel production

- Textile industry

- Flue gas desulphurization

- Primary titer substance according to pharmacopoeia

- Detoxification of nerve agents

- Increase in the pH value of drinking water as well as in swimming pools ("pH plus powder" and granules are usually sodium carbonate)

- Addition to developer solutions

Web links

Individual evidence

- ↑ a b c sodium carbonate, E 500 , In: Lebensmittellexikon.de

- ↑ Entry on E 500: Sodium carbonates in the European database for food additives, accessed on August 11, 2020.

- ↑ Entry on SODIUM CARBONATE in the CosIng database of the EU Commission, accessed on February 26, 2020.

- ↑ a b c d e f g Entry on sodium carbonate in the GESTIS substance database of the IFA , accessed on February 21, 2017(JavaScript required) .

- ↑ a b c d Sodium carbonate data sheet (PDF) from Merck , accessed on March 18, 2012.

- ^ Ray E. Bolz: CRC Handbook of Tables for Applied Engineering Science . CRC Press, 1973, ISBN 978-0-8493-0252-7 , pp. 482 ( limited preview in Google Book search).

- ↑ Entry on sodium carbonate in the Classification and Labeling Inventory of the European Chemicals Agency (ECHA), accessed on February 1, 2016. Manufacturers or distributors can expand the harmonized classification and labeling .

- ↑ David R. Lide (Ed.): CRC Handbook of Chemistry and Physics . 90th edition. (Internet version: 2010), CRC Press / Taylor and Francis, Boca Raton, FL, Standard Thermodynamic Properties of Chemical Substances, pp. 5-20.

- ↑ Explanation of the differences between soda and baking soda, accessed in June 2016

- ↑ Otto Krätz , Beginnings of Technical Chemistry, in: Armin Hermann , Charlotte Schönbeck, Technology and Science, VDI Verlag 1991, p. 308

- ↑ Bernhard Neumann (Ed.), Textbook of Chemical Technology and Metallurgy, Volume 1, Springer 1939, p. 364

- ^ Arnold F. Holleman, Egon Wiberg: Textbook of inorganic chemistry . Walter de Gruyter, 1995, ISBN 978-3-11-012641-9 , pp. 1182 ( limited preview in Google Book search).

- ↑ a b c R. E. Dickerson, HB Gray, H.-W. Sighting, MY Darensbourg: "Principles of Chemistry", Verlag Walter de Gruyter 1988, ISBN 9783110099690 , p. 976. ( limited preview in Google book search)

- ^ Hermann Schelenz: History of Pharmacy . Springer publishing house. Berlin, Heidelberg. 1904. p. 41. ISBN 978-3-642-52552-0 .

- ↑ Entry on flux. In: Römpp Online . Georg Thieme Verlag, accessed on March 22, 2011.

![{\ mathrm {\ \! \ {\ Biggr]}}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/c9fd9553a0b623f5f669641be907d9186e35b739)