Washing machine

A washing machine is used to clean laundry items. In the washing machine, mechanical forces, detergent and (heated) water act in combination on the laundry. Detergents are usually added to the washing water which, like the washing water temperature, are adapted to the material to be washed and its degree and type of soiling. Washing machines are used in households as well as in the cleaning industry to clean clothing and other finished textile products .

The mechanization of the "big laundry " by washing machines was a major turning point in everyday housewives. It took a long time, however, until all-round satisfactory types were developed.

History of the washing machine

From the 17th century onwards, interest in washing machines arose , in which mechanical force was used to replace or at least make the strenuous rubbing, rubbing, compressing, beating and brushing of the laundry items easier when washing by hand . In the course of the following centuries, a large number of different washing machine designs were created in which either a moving element directly stirred or moved the laundry in a container filled with detergent solution or the container moved with the laundry itself in order to compress, fall and rub against each other Laundry to reach.

On August 22, 1691, John Tizack (also Tyzacke) was granted the English patent no. 271 issued to a machine which, in addition to a large number of applications, should also be able to be used for washing textile materials. A detailed description of the construction is not given in the patent specification

The use of a washing mill, which is operated like a fulling mill , for washing laundry in a Norbertine monastery in the Eifel was reported in 1757.

As early as 1752, a washing machine was described in a magazine known as the Yorkshire Maiden. A wooden tub was filled with the laundry and hot soapy water. A wooden rod was led through the middle of the lid, which had a handle at the top for turning and at the bottom a wooden disc with embedded wooden pegs, which moved the laundry in the soapy water when turned back and forth. The size of this washing machine and the manual operation made it suitable for smaller households. This type of washing machine is said to have been in use in Yorkshire for a long time at the time of this report and to have spread to other counties in England. This type of washing machine with one or the other small variation also came to Germany from England and was probably already in use there in Hanover in 1740, and later became known in Braunschweig, Hamburg, Leipzig (1746) and Augsburg (1761). This type of washing machine and a drawing of how it was used in Braunschweig was described as early as 1756.

This washing machine construction, as it was used in Braunschweig, was the basis for the replica by Gotthard Friedrich Stender at the beginning of the 1760s, which he had done in Copenhagen on behalf of Freyherrn von Korff. A magazine article in 1766 in which Stender announced his replica of the English washing machine, Jacob Christian Schäffer procured such a washing machine and, after testing it, made some improvements while maintaining the basic construction and the washing principle (e.g. type of wood, adding a drain of the zuber ). The principle of moving the laundry with wooden pegs used in these first washing machines remained a principle that has been copied over and over again for decades. Even up to the Second World War, tenon washing machines, some even with electric drives, were to be found in Thuringia and Saxony.

From the last third of the 18th century, the development of washing machines increased particularly in England, which was reflected in the patent applications. In the years between 1780 and 1793 alone, 13 patents were registered for washing machines, 10 of them in the years from 1789 to 1793 (corresponding to the building boom at that time). This trend continued in the 19th and 20th centuries. Over 20,000 patents relating to washing machines were registered in the US Patent Office between 1790 and 1975.

For many decades, the use of washing machines without their own heating and with manual operation remained. Hot washing liquor was usually added to the containers. In addition to the tenon washers already mentioned, a distinction is made between the following types of laundry movement:

- Roller washing machines in which the principle of the washboard was imitated by moving the laundry through two grooved rollers.

- Brush washing machines in which brushes with stiff bristles were used instead of rollers.

- Cradle washing machines, in which the effect of the washboard was also to be imitated (brand name: Eckarts Universal washing machine), an arm was moved back and forth over a floor made of wavy cut wooden sticks.

- Rocking washing machines, also Silesian washing machines, in which a wooden container with an inner lining made of sheet metal and a closed lid was filled with laundry and hot detergent solution and rocked back and forth. From 1890 a swing washing machine made entirely of steel came on the market.

- Impeller machines in which impellers were used instead of the pegs, which thus acted more gently on the laundry.

Until the beginning of the 19th century, washing machines were still predominantly used in public and commercial laundries and large households and less so in private households or among individual professional laundresses. The washing machines were presented in numerous variations at industrial exhibitions. Even in Paris in the 1860s washerships with the washerwomen working with clubs and brushes could be seen on the Seine. Although washing machines were already widespread in some areas of Germany at this time, their general use was still pending. Towards the end of the 19th century, trial washing days with show washing were even held in large cities to advertise the then new technology.

In 1858 a drum washing machine was developed by Hamilton Smith . Around 1902, the German Karl Louis Krauss developed a mechanical washing machine with a perforated washing drum and subsequently produced it in series from 1906.

The electric drive of mechanical washing machines (and other household appliances) appeared around the turn of the 19th and 20th centuries; on an industrial scale, electric washing machines were manufactured from around 1907 and 1908 by the “1900” Washer Company in Binghamton ( New York ) and the Hurley Machine Co. in Chicago (brand name Thor , based on patents from Alva J. Fisher ).

The first fully automatic washing machine was launched in America in 1946 and in Germany in 1951. From the mid-1950s it became customary in some places to rent washing machines to private households on a daily basis, as is still the case in the Dominican Republic today.

The proliferation of washing machines in households led to a “dramatic reduction” in the time required for laundry care, which, however, was partially canceled out by the simultaneously increasing hygienic and aesthetic demands on the cleanliness of the laundry.

In the 1960s and 1970s, washing machines became the affordable standard in industrialized countries, while they are still the privilege of a minority worldwide today. It is estimated that only two (out of seven) billion people have access to washing machines.

Washing machines in the Neuhausen ob Eck open-air museum

The Irrel farming tradition is shown in the oldest Miele washing machine in the Roscheider Hof open-air museum

Miele washing machine "Extra" in the historic department store

One of the first fully automatic machines from Constructa

Household machines

A washing machine usually requires an electricity, fresh water and waste water connection. Some washing machines avoid heating the water with electricity and instead use natural gas or are connected (additionally or exclusively) to the central hot water supply of the house installation.

The cycle of a washing process is called a wash cycle . It is divided into different time phases. The fully automatic washing machines , which are exclusively used in Germany today, take care of the sequence automatically, with electronics with a microcontroller usually taking over the control. In the inexpensive segment, however, mechanical program switches can also be used . The course of the washing process:

- soaking

- as necessary; with some devices automatically, otherwise manually: for loosening soakable (especially protein-containing) impurities

- prewash

- is used to rinse out large amounts of dirt (dust, sand) from heavily soiled work and children's clothing

- Main wash or main wash

- The wash liquor and mechanics have an effect, the dirt is removed from the laundry

- do the washing up

- Remnants of the washing liquor including the loosened dirt are rinsed out in several rinse cycles

- Fabric conditioner / starch

- Fabric care products that should remain in the laundry ( fabric softener , starch , impregnation) are washed in in the last rinse

- Final spin

- drains the soaking wet laundry

Drum washing machine

The most common design in Europe today is the drum washing machine, in which a laundry drum rotates around a horizontal axis.

Top loader and front loader

A distinction is made between top loaders , in which the loading hatch is on the top, and front loaders, where a porthole on the front usually serves as a loading hatch. The advantage of the top loader is that the door can be sealed more easily and the drum can be supported on two sides by roller bearings ; A top loader can also be set up where there is not enough space to open a front door. A front loader, on the other hand, offers space for z. B. a tumble dryer or for a work surface and is therefore occasionally built into a kitchen unit instead of a base unit.

Aquasensor

Miele, Gorenje, Siemens and Bosch devices are offered with a so-called aqua sensor. This measures the turbidity of the (x-rayed) wash liquor to determine whether further rinse cycles are necessary.

Aquastop

To prevent water damage, higher quality devices with Aquastop are offered. In the event of a leak in the inlet hose, a safety valve, which is located directly at the tap, interrupts the water supply. Some devices also have a float switch built into a floor pan, which interrupts the water supply if water escapes in the device and at the same time activates the drain pump.

Load sensor

A load sensor is a function in washing machines that provides information about the respective load level of the washing machine and the resulting amount of detergent required.

Real load sensors detect the lowering of the tub during loading of the drum. From this u. a. the required amount of detergent and the washing time can be determined.

If the load sensor is connected to a display, energy can be saved. You can see at a glance whether the loading capacity of the washing machine has been fully used or whether laundry can still be reloaded. The optimal loading capacity depends on the selected laundry program and the respective type of laundry.

Lint filter

The lint filter is used to hold back coarse parts from the rinse water in order to prevent mechanical damage to the drain pump. It should therefore be cleaned regularly, this also increases the speed, performance, reliability and energy efficiency of the washing machine in question. In some machines, instead of filtering the water flow, the 180 ° deflection means that only very coarse or long foreign bodies such as toothpicks, screws or nails are retained; Lint can pass unhindered.

Air trap

The water level is determined with the aid of a water hose that is led up from the bottom of the tub and is closed there: if the water level in the machine rises, the water level in the hose section also rises and the air trapped above is compressed. The increased air pressure in this air trap (also known as the dome ) is evaluated with several pressure switches (for different water levels) or with a pressure sensor , depending on the model .

The majority of dishwashers also use the same technology for determining the water level .

There is only a slight movement of water within the air trap. It is hardly flushed through, so that dirt can collect here. Malfunctions due to incorrect water level measurement can often be rectified by cleaning the air trap.

Quantity automatic

Some models have a so-called quantity automatic . This controls the dosage of the required water as well as the detergent and fabric softener, provided the latter are supplied via the detergent container. The control is electromechanical or electronic and depends on the filling quantity and the selected washing program.

Machines with automatic quantity control only allow a certain amount of water to flow in after the start of the washing program. The water level is precisely monitored with a pressure switch . Depending on the type and amount of laundry loaded, it will absorb some of the water that has run in. After a certain running time, usually during the pauses between the reversal of the direction of rotation of the washing drum, more water is added until the target level is finally reached. By comparing the amount of water supplied per time segment with the corresponding increase in the water level, the control can estimate the amount of laundry.

Alternatively, the electrical power required to move the drum is determined by measuring the power consumption of the drive motor. Since the laundry items can each be transported upwards by almost half a revolution before they fall down again, conclusions can be drawn about the amount of laundry from the power required for the constant upward movement of the laundry.

Reduction of detergent loss

In 1986 AEG offered the first washing machine with a so-called “eco-lock” to save detergent. Depending on the manufacturer, a ball valve or a flap prevents part of the let-in water from collecting unused in the drain pump and its connection hoses. This is where the water that was first let in, which contains the largest amount of detergent from the dispensing compartment and which would be lost for the washing process, runs. Previously, it was often recommended that the detergent only be added approx. 15–60 seconds after the program had started.

Unbalance control

Household washing machines of almost all brands are equipped with imbalance detection. With devices from Bosch and Siemens , the motor speed signal is evaluated for this. Before the spin ramp-up, the drum is activated at 100 / min, then it is reduced to 75 / min. The deceleration behavior is evaluated by the electronics using the motor tacho signal (actual value transmitter in the motor). This query can be made several times, followed by loosening the laundry by moving the drum back and forth. If the drum is unbalanced, the final spin speed is gradually reduced, up to and including the termination of the spin if the unbalances are too large. V-Zug appliances use a system in which specially let water in the drum area (separate from the laundry) compensates for the unbalance during spinning. This eliminates the need to reduce the spin speed.

Small, old Eudora washing machines contained a pendulum, which was deflected when the machine vibrated strongly and activated a contact which caused the machine to stop the spinning process and rearrange the laundry.

Rinse hold

The flush stop function (also flush stop ) can be selected manually. It ends the wash program before the rinse water from the last rinse cycle has been pumped out. The laundry remains in the rinse water. This prevents sensitive textiles from creasing when they are spun or when they are stored in the drum for a long, dry period . Before removing the dripping wet laundry, the rinsing water is pumped out by manually selecting the appropriate program point.

Circulation system

A few washing machines are equipped with a flooding system. During the washing process, a circulating pump repeatedly pumps the lye through a flow heater and returns it to the laundry. In this way, the amount of wash liquor can be reduced, which means that water consumption and, in particular, the electricity required to heat the liquor are reduced. In addition, the detergent is used more efficiently and detergent that may have got into the pump sump is reused. In a small sump, such as the piece of hose to the drain pump, coarse impurities should be able to settle, which is why the circulation pump removes the caustic solution from a little higher.

Hot water connection

In addition to the conventional cold water connection, some devices can also be connected to a central hot water supply. This can save energy. A possible disadvantage is that, on the one hand, protein-containing soiling is fixed in the tissue through denaturation and is then difficult to wash out if water runs in at temperatures above 40 ° C at the beginning of the washing process, and on the other hand, the enzymes added to the detergent to hydrolyze proteins and fats destroyed and thus become ineffective.

Since today washing is usually done at lower temperatures and water levels, the possible savings compared to the conventional method are no longer as significant as in the 1990s.

Washing machine with heat pump

Energy-efficient washing machines with a development status from 2013 use a heat pump instead of an electrical resistance heater to heat the water. This reduces the need for electrical energy.

During the heating process, the cleaning water mixed with detergent is pumped through the condenser of the heat pump (warm side). A heat flow is transferred from the refrigerant to the cleaning water and heated. The heated cleaning water then flows back into the storage tank. The heat pump's evaporator (cold side) is located in a waste water tank. The wastewater stored in it serves as a heat source, i. H. A heat flow flows from the wastewater to the refrigerant, which evaporates. The wastewater cools down and freezes. After the wash program, the still warm waste water flows into the waste water tank and melts the frozen waste water. This recovers part of the heat energy in the warm wastewater. By melting, the cleaning water for the next wash program can be heated up again with the aid of the heat pump, thereby ensuring continuous operation. All components for the heat pump unit are housed in the standard housing of a washing machine.

The benefit of this heat pump is the heat flow in the condenser, which heats the process water. The effort is the electrical output of the compressor of the heat pump, the drum drive and the cleaning water pump. An essential key for increasing the efficiency and operation of the heat pump is the recovery of the normally "lost" heat energy in the pumped waste water with the heat pump.

Washing machines with heat pump technology for a single family house reduce the need for electrical energy compared to conventional washing machines by 17% to 60% (as of 2015). These washing machines correspond to the energy efficiency class "A +++".

The energy efficiency chapter also includes the display of the amount of energy expected to be required. This ECO-Monitor was introduced around 2012 and an extended procedure under GM1 was submitted in Austria for protection in 2012.

Washer dryer

A special design is the combination of the washing machine with a tumble dryer in one device, a so-called washer - dryer .

Tub washing machine

The machines, marketed since the mid-1940s, are mainly built and used in the USA , Asia and Australia . Tub washing machines were also known in Germany in the past, but have now almost "died out" in this country; the last widespread model was the WM 66 produced in the GDR . There is a standing wash tub, the washing function is carried out by a centrally arranged agitator arm rotating around the vertical axis, which moves the washing water, or rotating ribs on the floor, which move the laundry in the washing water.

The wash tub consists of a perforated drum made of enamelled metal or stainless steel in a watertight tub. The agitator (stirrer) and the water inlet are located in the middle of the vat with lamellas or other structures. When the water level is reached, the agitator is started. This makes half a turn to the right and to the left and moves the detergent solution or the laundry, whereby a mechanical washing process takes place. The lye is disposed of via an electric pump. The entire drum rotates to spin the laundry.

The devices can be made lighter than European fully automatic washing machines because they do not require any weighting to reduce vibration amplitudes . Due to the larger washing drum, the centrifugal force required to spin the laundry is achieved even at low speed, whereby unbalances or associated vibrations and possible "wandering" of a free-standing machine are hardly apparent (see also vibratory spiral conveyors and oscillating conveyors ). This leads to a reduced bearing load . The tilting moment of front loader washing drums does not apply with a vertical axis of rotation. The machines do not have their own heating, but are either fed by the house's hot water supply or wash without heating. The tubs are usually designed for a larger amount of laundry (6 kg and more) and have a hinged lid to avoid accidents.

The advantage of tub washing machines is that they are more gentle on the laundry, less creases (swim washing process), and shorter overall washing times, as several loads can be cleaned one after the other in the once prepared liquor, especially if the washing can be done outside the machine by hand or by a spin dryer. “Wash buffet” or “twin tub” designate machines that are designed to handle two loads at the same time.

Disadvantages of tub washing machines

Tub washing machines have several disadvantages over drum washing machines.

- Tub washing machines need more water per wash or rinse cycle. The consumption per wash cycle is approx. 100 to 150 liters. Drum washing machines , on the other hand, manage with less than 50 liters (both values aliquoted based on 5 kg of laundry). The common tub machines for 9 kg of laundry accordingly need even more. In drum washing machines, less water is required per wash or rinse cycle because the drum movement completely wets and rinses the laundry items even when the water level is low.

- Tub washing machines use more electricity. The Environmental Protection Agency , according to a washing machine with a vertical axis of rotation requires about twice as much electricity as one of the usual European machine on a horizontal axis (H-axis machines), since the 2000s years front loader washing machines are also increasingly in North America is in use. They are marketed under the name HE washing machines. ("HE" stands for high efficiency ).

- Tub washing machines often have no built-in electrical heating. However, some versions have two water connections. This allows you to set the temperatures "hot" (only hot water), "warm" (cold and hot water mixed) and "cold" (only cold water).

Hammer washing machine

The hammer washing machine is an outdated form, which has not caught on due to the greater stress on the laundry and probably also the more space-consuming construction.

Commercial and industrial machines

Commercial washing machines differ from household machines in particular because of their more powerful motor and loading capacity. Both washer extractors and continuously operating washing lines (continuous systems) are used in industrial laundry. Application criteria include a. the amount and nature of the items to be washed. In order to minimize costs, industrial machines have long been designed for resource-saving operation. For example, it is often possible to use certain washing and rinsing baths multiple times by recovering the liquor, thus reducing water and energy consumption. For special hygienic requirements (e.g. hospital laundry), the machines are designed so that they are accessible from two separate rooms. Loading takes place on the unclean side and unloading on the clean side. The machines are heated by superheated steam, thermal oil or electrically. Programmable logic controllers are often used. The washing cycles are also often shorter, usually around 40 minutes per wash load, in order to increase throughput.

Washer extractors

Washer extractors are basically similar to the household drum machines described above, but are naturally designed for significantly higher capacities. In order to ensure an even distribution of the mass and the necessary washing mechanics, larger washing drums are divided into two to four chambers. Loading and unloading takes place on the front or on the shell side, depending on the design.

Continuous systems

Continuous systems are washing lines that work continuously or intermittently, in which the items to be washed are washed fully automatically and continuously, without machine downtime due to loading and unloading.

Coin-operated washing machines

Coin-operated washing machines are self-service washing machines that pay with coins. They are often found in self-service laundries , on campsites or in washrooms in larger apartment buildings. The coin slot and the associated mechanics are often arranged centrally: after the corresponding coins or tokens have been inserted, the power supply for the selected machine is enabled. In this way, standard washing machines can also be set up and protection against theft is easier to implement.

Networking

Premium brands have started to offer home appliances with interfaces for networking via the Internet, predominantly in powerline technology. The aim of the manufacturers is to create new (remote) control options.

Liquor ratio

The liquor ratio is the ratio of the amount of laundry to the volume of water in a washing machine. The ideal liquor ratio is 1: 5, i.e. H. 1 kg of laundry in 5 l of water (see liquor ).

But this only applies to drum and ball washing machines. A liquor ratio of 1:10 is required for washing kettles and washing pots in which the laundry is only boiled or cleaned with whirlpool inserts - also known as washing fountains, for wash tubs or wash tubs in which washing is carried out by hand , washing bells, washboards or sonic washers ; the same applies to soaking in tubs, bowls or buckets.

In tub washing machines, a liquor ratio of 1:15 to 1:20 is provided. Also for agitator and beater washers, washboard machines, rocking washing machines and pendulum basket washing machines. For bell washing machines, wave wheel washing machines (also called turbo, high-speed or pulsator washing machines ) and swash plate washing machines 1:20 to 1:25 are required.

Pump washing machines require the highest liquor ratio, namely 1:30. The liquor ratio only indicates the amount of water necessary to achieve an adequate washing effect. The washing liquor is not necessarily "used up" after a wash cycle. Five liters are generally sufficient for one kilogram of dry laundry. This means that several wash loads can be cleaned in the same liquor.

Germs and impurities

Current washing machines are designed to be highly effective in terms of energy and water consumption. A large part of all washes are carried out at temperatures below 60 ° C. This saves water and energy, but leads to detergent residue in the washing machine and promotes mold growth, which can also lead to odor. It is therefore recommended that the washing machine be cleaned regularly by means of a boiling wash at 60 ° C and, if slime has already been deposited, at 95 ° C. According to Stiftung Warentest , many washing machines do not reach a water temperature of 50 ° C in the 60 ° C Eco program, but only in the 60 ° C normal program. The normal program should therefore be used to clean the washing machine.

Higher washing temperatures, the pH value of the washing liquor and various detergent ingredients or detergent additives that kill fungi as well as ironing the dried laundry can kill microorganisms, but germ reduction is still sufficient at low washing temperatures for non-iron laundry. The risk of germs from the machine being carried onto textiles is low. Some pathogens or their spores (e.g. from clostridia ) are heat-resistant and could not even be removed by boiling the laundry.

If items of clothing are contaminated with harmful or radioactive substances, these items of clothing are decontaminated in a separate washing machine and the harmful substances should also be removed from the wastewater. To avoid these complex procedures, either disposable protective clothing is worn or contaminated laundry is disposed of as waste. While chemically soiled textiles can be processed by incineration and flue gas cleaning, radioactively contaminated protective suits require permanent, guarded storage.

Microplastics

In 2011 the journal Environmental Science & Technology reported on a study on beaches that found microplastics on all continents ; including synthetic fibers from clothing items (e.g. fleece ): up to 1,900 fiber particles can be found in the wastewater from washing machines per wash cycle. Fleece is suspected of polluting the world's oceans . With each wash cycle, plastic fibers are detached from the laundry as microplastics, which cannot be collected by sewage treatment plants . Such particles were found in the sediment of 18 beaches worldwide , not a single sample was free of them. To prevent this, clothes made from synthetic fibers can be washed in a laundry bag or they can be exchanged for clothes made from natural fibers . In addition, one study showed that during the washing of polyester - T-Shirts come in the gentle cycle compared to other washing programs average of 800,000 additional microfibers in the wastewater.

Effectiveness and standards

Europe

Since the Energy Consumption Labeling Ordinance came into force on January 1, 1998, manufacturers of various household appliances , including washing machines, have been obliged to assess each appliance according to certain environmentally relevant criteria. This assessment takes place under laboratory conditions and leads to a division of the device into different classes. This classification is attached to the device as an EU energy label . The test principles and laboratory conditions for determining the performance characteristics of washing machines were laid down in 1974 in the international standard IEC 456 and in the German DIN EN 60456.

Washing machines are classified according to their energy efficiency class , washing efficiency class and spin efficiency class . The evaluation in each class is between A and G , with A being the best and G the worst. With the EU regulation 1015/2010, the sale of devices with energy efficiency class B and lower was prohibited in Europe from December 2011. In addition, the new energy efficiency classes A + , A ++ and later also A +++ were introduced. Furthermore, the evaluation criteria were redefined.

However, this assessment only relates to the processes occurring during operation. So z. B. the power consumption in standby mode is not recorded, which extrapolated over the lifetime of modern devices can amount to several hundred euros. In particular, the energy efficiency class relates to washing in Eco mode; the washing operation without activating the eco mode typically drops significantly, e.g. T. many times higher. The Blue Angel seal of approval includes these aspects.

United States

For top-loading and front-loading washing machines, there is a statutory standard that defines the energy consumption. The old standard used until January 2011 did not include any restrictions on water consumption. In this regard, washing machine manufacturers did not seek any legal restrictions on the extent to which unheated dishwashing water was used. The energy consumption for washing machines is classified and evaluated with the energy factor.

After the introduction of new binding standards, the machines were built to save energy and water as required by law. Some of them have been certified by the even stricter Energy Star standard.

The Energy Star program in North America lists and compares the energy efficiency of washing machines. Energy factor (IMEF) and water factor (IWF) are compared for certified Energy Star devices. The IMEF essentially shows the amount of clothes per kilowatt hour being washed in one go. This factor correlates strongly with the type of washing machine (top loader, front loader), the spin speed, temperature and the amount of water required per rinse and wash cycle. The IMF describes the amount of water consumed in relation to the amount of clothing.

Energy Star washing machines must have an IMEF of at least 2.06 for top loading and 2.76 for front loading (the higher the better), with the best machines scoring 3.5. The IWF must not exceed 4.3 for top loaders and 3.2 for front loaders (the lower the better).

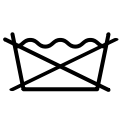

Washing symbols

Washing is represented by a stylized washtub ; the number in the tub means the maximum permissible washing temperature (in degrees Celsius). The symbol allows both hand and machine washing. If there is no special note, a normal wash cycle is permitted. A bar under the tub (underlining) requires a mechanically gentler treatment, i.e. an easy-care or gentle wash program in the machine (drum only half full of laundry, high water level, gentle spinning). A tub that is underlined twice requires particularly gentle treatment, e.g. a wool wash cycle or a gentle cycle (drum only 1/3 full of laundry, increased water level, greatly reduced movement, wool spin or no spin at all). One hand in the tub allows only (gentle) hand washing (not over 40 ° C), and a diagonally crossed tub means that the textile must not be washed at all under normal household conditions.

Washing machine in German tenancy law

Tenants are allowed to set up a washing machine in their apartment. This is part of the contractual use of the apartment. The neighbor has to tolerate washing machine noise until 10 p.m. Includes a tenant's washing machine without AquaStop apparatus, that he is liable for a (by this preventable) Water damage .

See also

- Golf ball washing machine

- Wave gear washing machine

- washroom

- Carrier

- Spin dryer

- Lint sieve

- Textile care symbol

- Water switch

- White goods

- Dosing aid

- Animal washing machine

- Sinner Circle

- Washing card system

- Washing machine counter switch

- Ecodesign Directive Lot 14 (private) and Lot 24 (commercial)

Web links

- How does a washing machine work? In: Science in Dialog . March 29, 2008.

- Who Invented the Washing Machine and Dryer? In: LoveToKnow. (English).

- Lee Maxwell Washing Machine Museum. In: oldewash.com. (English).

literature

- Günter Bayerl: "And secondly, men, if they have nothing else to do, can take care of this part of the laundry business." Washing in the early modern era and the innovation of the washing machine. In: Uwe Bestmann (Ed.): High finance, economic areas, innovations. Volume III, Auenthal, Trier 1987, ISBN 3-89070-014-4 , pp. 1063-1099.

- Friedrich Bohmert: Mainly clean? About washing and cleaning through the ages. Stürz, Würzburg 1988, ISBN 3-8003-0329-9 .

- Elisabeth Helming, Barbara Scheffran (Red.): The big laundry. (= Catalog for an exhibition of the Rhineland Regional Council and the Rheinisches Museumamt). Rhineland, Cologne 1988, ISBN 3-7927-1057-9 .

- Franziska Lobenhofer, Traudl Nonnenmacher: Laundry and laundry care are changing . Exhibition booklet. (= Writings of the open-air museum of the district of Upper Bavaria. Volume 12). Open-air museum of the district of Upper Bavaria on the Glentleiten / Amerang farmhouse museum, 1987, ISBN 3-924842-12-4 .

- Barbara Orland: Do the laundry. Technical and social history of home laundry care. (= rororo 17736). Rowohlt, Reinbek near Hamburg 1991, ISBN 3-499-17736-6 . (At the same time dissertation : Technical and social history of home laundry care in Germany since the 18th century. At the Free University of Berlin 1991)

- Lutz Pape, Hans-Jürgen Weinert: tub washing machine and house telegraph. Beginnings of electrical engineering in the household . Westermann, Braunschweig 1993, ISBN 3-07-509513-3 .

- Franz Severin Berger, Christiane Holler: From the laundress to the miss from office. Women's work through three centuries. Ueberreuter, Vienna 1997, ISBN 3-8000-3661-4 .

Individual evidence

- ↑ Joachim Radkau: Technology in Germany - From the 18th century to today . Campus Verlag, Frankfurt am Main 2008, ISBN 978-3-593-38689-8 , p. 249.

- ↑ Barbara Orland: Washing clothes - technical and social history of domestic laundry care. Rowohlt Taschenbuch Verlag, Reinbek bei Hamburg 1991, ISBN 3-499-17736-6 , p. 93.

- ↑ Spin, wash, rinse - the achievement of the washing machine and its history. Retrieved June 3, 2020 .

- ^ Description of the patent by John Tizack - Internet Archive

- ↑ report. In: Braunschweigische advertisements , May 14, 1757, column 687; Text archive - Internet Archive .

- ^ Description of the Yorkshire Maiden tub washing machine in 1752 . Retrieved April 15, 2016.

- ↑ On the spread of the English washing machine in Germany . Retrieved April 16, 2016.

- ↑ Georg Heinrich Zincke: Leipzig collections of economic, policey-chamber and financial affairs collections. Verlag Carl Ludwig Jacobi, Leipzig 1756, 136th item, p. 318 ff.

- ↑ The most convenient washing machine from Stender . Retrieved April 16, 2016.

- ^ Jacob Christian Schäffer: The convenient and extremely beneficial washing machine. Description of his washing machine. Retrieved April 16, 2016.

- ↑ Barbara Orland: Washing clothes - technical and social history of domestic laundry care. Rowohlt Taschenbuch Verlag, Reinbek bei Hamburg 1991, ISBN 3-499-17736-6 , p. 94.

- ↑ Josef Kurz: Cultural history of domestic laundry care: women's work and household technology as reflected in the centuries. Wachter-Verlag, Bönnigheim 2006, ISBN 3-89904-248-4 , p. 172.

- ↑ Christine MacLeod: Inventing The Industrial Revolution - The English patent system, 1660-1800. Cambridge University Press, Cambridge 1988, ISBN 0-521-30104-1 , p. 155.

- ^ Lee M. Maxwell: Save womens lives: history of washing machines. Oldwash, Eaton 2003, ISBN 0-9729710-0-9 , p. 11.

- ↑ Josef Kurz: Cultural history of domestic laundry care: women's work and household technology as reflected in the centuries. Wachter-Verlag, Bönnigheim 2006, ISBN 3-89904-248-4 , pp. 168-184.

- ↑ Barbara Orland: Washing clothes - technical and social history of domestic laundry care . Rowohlt Taschenbuch Verlag, Reinbek bei Hamburg 1991, ISBN 3-499-17736-6 , p. 93.

- ↑ Otto Buchner: The latest, best and most common washing facilities, based on personal observations at the Paris World Industry Exhibition of 1867, and using technical literature, with special consideration of German conditions for households, factories, public institutions and mechanical engineers . Verlag Bernhard Friedrich Voigt, Weimar 1868, p. 3.

- ↑ Description of a test wash in Innsbruck in 1889 . Retrieved April 27, 2016

- ↑ US Patent US27391 A. Inventor: Hamilton E. Smith, published March 6, 1860.

- ^ Congressional series of United States public documents 1865– '66 . United States Government Printing Office, Washington 1866, p. 833, Text Archive - Internet Archive .

- ↑ The Krausswerke in Schwarzenberg ( Memento of the original from April 30, 2016 in the Internet Archive ; PDF; 7 MB) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ^ Peter Sundermann: 100 famous Saxons .

- ↑ Lee Maxwell: Who Invented the Electric Washing Machine? An Example of how Patents are Misused by Historians. 2009; oldewash.com (PDF).

- ↑ Business Ads . In: Berliner Adreßbuch , 1888, after part 1, p. 88.

- ↑ Wolfgang König: History of the consumer society , VSWG supplements, Franz Steiner Verlag Stuttgart, ISBN 3-515-07650-6 , p. 244, some of which can be viewed at Google Books

- ↑ Household appliances . In: Der Spiegel . No. 15 , 2016 ( online ).

- ↑ a b siemens-home.com

- ↑ siemens-home.com ( Memento of the original from August 25, 2012 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ verbrauchzentrale.de ( Memento from August 1, 2017 in the Internet Archive )

- ↑ BSH Hausgerätegesellschaft mbH Vienna

- ↑ Vibration Absorbing System (VAS). Retrieved March 11, 2015 .

- ↑ Circulation systems . hauswirtschaft.info, accessed August 10, 2016.

- ↑ A world first Adora SLQ WP with heat pump technology. Retrieved March 10, 2015 .

- ↑ Jürg Werner, Ernst Dober: Household washing machine with heat pump . In: patent specification . EP 2 096 203 B1, 2009.

- ↑ Topten.ch: Comparison of washing machines for single-family homes (EFH). (No longer available online.) Archived from the original on February 10, 2015 ; accessed on March 10, 2015 .

- ↑ Whirlpool's Eco Monitor guarantees energy optimization - The KBzine. In: thekbzine.com. Retrieved July 3, 2016 .

- ^ Tub washing machine , accessed on August 10, 2016.

- ↑ Clothes Washers - Energy Choices at the Home . California Energy Commission; accessed on January 13, 2011}

- ↑ washing machine . In: Meyers Konversations-Lexikon . 4th edition. Volume 16, Verlag des Bibliographisches Institut, Leipzig / Vienna 1885–1892, p. 408. - Facsimile shows a sketch of a hammer washing machine

- ↑ Washing machine stinks: How to remove musty smells - and prevent them in the future. In: focus.de. February 10, 2017, accessed March 24, 2018 .

- ↑ Temperature dizziness in the washing machine. Stern , December 29, 2012, accessed October 31, 2019 .

- ↑ Washing machines - long washing times and lukewarm temperatures. Stiftung Warentest , accessed on October 31, 2019 .

- ↑ W. Lichtenberg, F. Girmond, R. Niedner, I. Schulze: Hygiene aspects in low-temperature washing . ( Memento from February 21, 2014 in the Internet Archive ; PDF)

- ↑ Radiation protection instructions for the nuclear chemistry / radiochemistry control area . Department of Chemistry at the Philipps University of Marburg

- ↑ External laundry service for nuclear facilities. ( Memento from February 27, 2014 in the Internet Archive ; PDF; 2.1 MB)

- ↑ What is disposed of in Konrad. ( Memento from February 10, 2013 in the web archive archive.today )

- ↑ Securvital - Das Magazin , 4/012, p. 5: Textiles - Fleece in the sea (November 24, 2012)

- ↑ Mark Anthony Browne, Phillip Crump, Stewart J. Niven, Emma Teuten, Andrew Tonkin, Tamara Galloway, Richard Thompson: Accumulation of Microplastic on Shorelines Worldwide: Sources and Sinks , Environmental Science & Technology , 2011, 45 (21), pp. 9175 -9179, doi: 10.1021 / es201811s .

- ^ Danger from microplastic waste , ORF , December 22, 2012

- ↑ Mélanie Guillebeau: Guppy Friend wash bag - no getting through for microplastics. In: naturschutz.ch. November 11, 2018, accessed May 5, 2019 .

- ^ Max R. Kelly, Neil J. Lant, Martyn Kurr, J. Grant Burgess: Importance of Water-Volume on the Release of Microplastic Fibers from Laundry. In: Environmental Science & Technology. 2019, doi : 10.1021 / acs.est.9b03022 .

- ↑ Brigitte Rohm, Lino Wirag: Study shows: significantly more microplastics dissolve in the gentle cycle. In: oekotest.de . September 27, 2018, accessed September 28, 2019 .

- ↑ Clothes Washers Key Product Criteria. Energystar.gov, accessed April 22, 2015 .

- ↑ ENERGY STAR Qualified Clothes Washers. Energystar.gov, January 1, 2011, accessed April 22, 2015 .

- ↑ Clothes Washers Key Product Criteria . Energy Star; accessed on May 8, 2018

- ↑ Explanation of washing symbols and care symbols. Retrieved March 6, 2018 .

- ^ Washing machine is allowed in the apartment - Tettnang District Court, judgment of March 19, 2010, 4 C 1304/09, free-urteile.de

- ^ Neighbor has to put up with washing machine noise - Wedding District Court, judgment of January 26, 2004, 9 C 536/03, free-urteile.de

- ↑ No Aquastop device: tenant is liable for washing machine water damage - Higher Regional Court Oldenburg, judgment of May 5, 2004, 3 U 6/04, free-urteile.de