Differential pressure measurement method

The airtightness of a building is measured with the differential pressure measurement method (also: blower door test ) . The method is used to detect leaks in the building envelope and to determine the actual air exchange rate .

Legal requirement

The goal of every building project should be to achieve optimal living comfort and to minimize the energy used. To do this, it is necessary to create a relatively airtight outer shell on every building. In the German DIN 4108 , Part 7, for example, the "installation of an air-impermeable layer over the entire surface" is required. The DIN sets binding limit values for the air exchange rate n50, so a new building has the right to a certain airtightness, which can be proven by the differential pressure measurement. According to today's standards, every building must have a planned, gap-free, sealing level between the interior and exterior. This becomes more and more important with increasing insulation thicknesses, because the heat transfer through well-insulated components is very low, but loses its efficiency if a large part of the supplied energy is lost through convection through leaks. The leak detection in the shell state with the help of a negative pressure generated in the building allows leakages to be detected. These can be fixed without great effort before the cladding is installed. In this way, energy can be saved in the long term and the risk of structural damage and a reduction in the insulation effect due to condensation in the insulation materials during the winter period can be reduced.

The differential pressure method is standardized in ISO 9972: 1996 and the subsequent EN 13829 Thermal behavior of buildings - Determination of the air permeability of buildings . Differential pressure method according to DIN EN 13829: 2001-02.

Measuring principle

A fan pushes air into or out of the building to be examined. Measuring orifices of different sizes for the conveyed volume flow are used to adapt the conveyed air flow to the tightness of the building . The size of the volume flow is displayed by calibration . The speed-controlled fan is set so that there is a pressure difference of 50 Pa ( Pascal ) to the ambient pressure . Pressure differences also arise of course when z. B. Wind blows and hits a surface like a house wall. The resulting pressure difference with wind load depends on the area and wind speed, which wind strength corresponds to the pressure difference of 50 Pa, i.e. it depends on the size of the measuring object.

The fan is inserted into a door or window opening by means of an adjustable metal frame, which is surrounded by an air-impermeable tarpaulin. The frame is pressed into the door or window frame via rubber seals. The name Blower-Door-Test (German: Blower-Door-Measurement) came about through the measurement in a door . The door or window in which the measuring device is used can of course not be measured. Since it is often very important to also measure the mostly large house doors, for the installation of the Blower Door device z. B. a balcony door can be used.

The blower itself generates an overpressure in the fan through the measuring orifices. Measuring instruments determine the two pressure differences:

- Pressure difference between outside and inside,

- Pressure in the fan - and thus the size of the air flow that the fan transports.

The speed of the fan is regulated in such a way that a certain pressure builds up between the outside and inside. During the negative pressure measurement, it has to convey as much air to the outside as penetrates the building through the existing leaks. The measured air flow is divided by the volume of the building. This value, the air exchange rate n50, can now be compared with other buildings and standards.

The Blower Door process offers the possibility:

- Determine the location and strength of the leaks (qualitative)

- Air flow (V50 in m³ / h) to be determined by the sum of all leakages at a test pressure of 50 Pa (quantitative)

- From this, with the room volume, calculate the hourly air exchange rate (V50 / V room = n50) at 50 Pa

Measurement phases

The blower door test is divided into three phases:

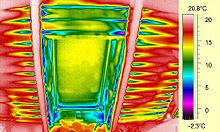

- In the first phase, a constant negative pressure of 50 Pa or slightly higher is created and maintained. During this phase, the building envelope is searched for leaks (leaks) where air flows in undesirably. When the building is later used, these leaks are the places where heated indoor air escapes to the outside. Larger flaws can already be felt by hand, for smaller ones smoke dispensers (smoke machines) or air speed meters are used . The most precise measurements of the air leaks are possible using an infrared camera . The detection of leaky areas is also reproduced very precisely and clearly by the infrared images. This enables targeted repair of the leaks at the sealing level of buildings.

- In the second phase, a negative pressure is built up, starting with low pressures (10 to 30 Pa) and increasing it gradually (e.g. in 5 to 10 Pa steps) to the final pressure (60 to 100 Pa). At each step, the respective air volume flow is measured and logged depending on the building pressure.

- In the third phase, an overpressure is generated and the measurement is repeated in the same way as the negative pressure measurement.

The mean air exchange rate (n50 value) is calculated from the total results of the overpressure and underpressure in the building. This indicates how often the air in the measured building is exchanged due to leaks at a reference pressure of 50 Pa in one hour. An n50 value = 2.5 h −1 means, for example, that the air in the building is exchanged 2.5 times in one hour due to air leaks at a pressure difference of 50 Pa. The exact sequence of the measurement is regulated in DIN EN 13829.

For a blower door investigation on a single-family house on site, a time of approximately 3 hours must be estimated. The prerequisite is that the volume and the area of the building are determined within the sealing level. After completing the measurements, the homeowner receives a certificate of the quality of the measured building envelope if the limit values according to the standard were not exceeded. These are currently 3.0 h −1 for residential buildings and 1.50 h −1 for residential buildings with a ventilation system .

Basic considerations

The differential pressure measurement method should be carried out on every new building and renovation in order to localize any defects in the building envelope at an early stage.

The EnEV ( Energy Saving Ordinance) rewards the performance of the blower door measurement. If the limit values are adhered to, a reduced air exchange may be applied and in buildings with a ventilation system the blower door measurement is part of the standard, since this technology may only be taken into account in the proof of energy demand with proof of tightness. Evidence is required for low-energy and passive houses .

Measurement is about two goals. First, the amount of air that the fan conveys and that escapes through unavoidable joints, etc., must exchange the air in the building a maximum of 3.0 times an hour (stipulated by the German Energy Saving Ordinance - EnEV, for buildings with ventilation systems a maximum of 1.5 times) and secondly, the person performing the measurement should also locate and document the defects so that they can be eliminated. It is therefore of no use to carry out a blower door test and then determine that the standard is not being complied with (the certificate cannot be created) without precisely locating the leakage points. The last requirement is not directly legal, but belongs to the generally recognized rules of technology . B. a building owner has a claim even without a special agreement.

Therefore, defects must be identified and eliminated in good time.

Typical air exchange rates as a result of the building tightness measurement are: 4 to 12 h −1 for leaky old buildings ; for new buildings without special care 3 to 7 h −1 ; for low-energy houses 1 to 2 h −1 and for passive houses 0.1 to 0.6 h −1 . Airtightness is particularly important in passive houses, which is why a limit value of 0.6 h −1 is specified there (measured at 50 Pa in each case).

A building must be ventilated (e.g. to remove moisture) - but only through the ventilation options provided. If room air (which is always moist) flows into the open due to defects in the construction (unwanted joints, slits, etc.), structural damage ( mold , etc.) is almost always programmed. Z. If, for example, damp room air is caused by mineral wool , there is a loss of condensation: In accordance with the function of mineral wool for thermal insulation, one side of the mineral wool is warm - the one facing the room - and the other side is cold in winter. If the room air comes into the cold area, the air is strongly cooled, the dew point is fallen below and condensation loss is the result. Because of the lack of accessibility, this condensation cannot be wiped off - as it is on the window. The only way to avoid this is to make the construction carefully airtight on the warm side (airtight layer).

Airtightness must not be confused with impermeability to vapor diffusion. A normal interior plaster on a masonry is z. B. Sufficiently airtight but open to vapor diffusion - the same applies to airtight paper. When creating an airtight layer, it is not about absolute tightness, but about avoiding convection, which is caused by the rapid escape of larger amounts of air through leaks.

It should be noted that airtightness often also improves sound insulation. Airtightness in terms of noise protection and odor nuisance are often an important aspect between different apartments within a house. With the differential pressure measurement, individual apartments can be assessed for their tightness.

See also

Web links

- Flyer for standardized thermography and blower door tests on buildings, published by the Federal Association for Applied Thermography - VATh (PDF; 204 kB) www.vath.de

- Flyer on airtightness, published by VATh and FLIB (PDF; 160 kB) vath.de

- Professional Association for Airtightness in Construction eV www.flib.de

- Thermography + Blower Door - Federal Association for Applied Thermography www.vath.de

- Thermography + Blower Door - Swiss Association www.thech.ch

- Minergie Blower Door Association Measurement Guide (PDF; 977 kB) Swiss MINERGIE Association - Guideline for air permeability measurements

Individual evidence

- ↑ Differential pressure measurement method (PDF; 5.5MB) fs-ev.de, accessed on January 2, 2015.