Embalse Katiri

| Embalse Katiri | |||||||||

|---|---|---|---|---|---|---|---|---|---|

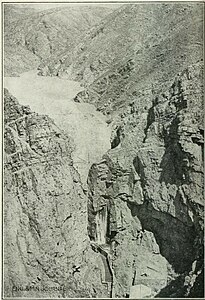

| Construction of the dam, around 1914 | |||||||||

|

|||||||||

|

|

|||||||||

| Coordinates | 18 ° 24 '54 " S , 66 ° 36' 58" W | ||||||||

| Data on the structure | |||||||||

| Construction time: | 1912-1915 | ||||||||

| Radius of curvature : | 559 mm (1 foot 10 in.), Sine | ||||||||

| Power plant output: | 3 × 235 kW (1915) | ||||||||

| Operator: | Llallagua Tin Mining Co. | ||||||||

| Data on the reservoir | |||||||||

| Reservoir length | 6500 m | ||||||||

| Reservoir width | 300 m | ||||||||

| Total storage space : | 20,000,000 m³ | ||||||||

The Embalse Katiri or Llallagua reservoir is a reservoir near Llallagua ( Quechua : "Llallawa") in the Potosí department in the highlands of the South American Andean state of Bolivia, which was completed in 1915 .

location

Fifteen kilometers from the Llallagua mine, the Río Katiri flows for a length of 500 m through a narrow gorge in the mountain and makes an almost right-angled curve at the narrowest point of this incision. At this point the incision was only 2 m wide at a height of 20 m. At a height of 60 m, the width was 30 m. Further up, the gorge widens to a width of 180 m.

Hydrology

The water of the Katiri river including its tributaries Uncia, Zauta and Challanta flows through this gorge. The amount of water fluctuates very strongly. The dry season in November is followed by heavy rains in spring from December to April. In the dry season, the total runoff of the rivers mentioned above is no more than 200 liters per second, while in the rainy season of the 1900s and 1910s the runoff often increased up to 70 m³ per second. The water comes from a catchment area of 8,000 to 10,000 hectares. Precipitation of 20 liters per square mile was occasionally measured prior to the construction of the dam. This irregular flow meant that all the water that fell during the rainy season had to be dammed up to ensure a constant power supply, as the flow would not have been sufficient to generate electricity in the dry season.

Design of the dam

In order to have enough head and water for the turbines all year round, a head of at least 30 m was required, with the dam being designed for an average head of 42 m. The dam was therefore designed for a height of 58 m, with an overflow weir that was supposed to maintain a water level of 55 m during the rainy season. It has been estimated that enough water can be stored in this way to provide electricity all year round. The resulting lake is 6500 m long with a width between 50 and 300 m and has a capacity for 18,000,000 to 20,000,000 m³ of water. The dam is built curved both horizontally and vertically. The horizontal arc has a sine of 1 foot 10 inches (559 mm) which was found advisable to withstand hydraulic pressure.

Construction of the dam

The dam is built of hewn stones laid with river sand and gravel, hydraulic lime and al-cement . The structure was reinforced on three different levels with I- and T-beams and steel cables. The dam foundation is 5 m below the river level and the crown is 58 m above the river. The base of the dam is 38 m thick. At a height of 55 m, the dam is three meters thick, with a 3 m high and 1.5 m thick crown. The water reaches the turbines through a 65 m long tunnel in which it flows through a 70 m long Mannesmann pipe with a diameter of 0.70 m. The turbine house is built for four turbines that are directly connected to their respective generators, three of which were already installed in 1915. The horizontal turbines built by Escher Wyss & Cie swallow 180 to 300 liters of water per second, depending on the water level, and develop 150 to 235 kW (200 to 320 hp). The generators run at 750 revolutions per minute and generate a voltage of 3000 volts, which is transformed to 10,000 volts to be transmitted to the mine. The line loss over 15 km is 150 volts. The line runs over the ground at an altitude of 3500 to 5000 meters above sea level.

The weir is located about a kilometer above the dam in the depression of a hill that is in the middle of the sharp curve of the river. The drained water flows into the river bed below the dam.

The dam already demonstrated its resilience and strength shortly after its completion, when it successfully withstood a flood with an overflow of one meter depth at the crown before the drainage canal was completed.

transport

The three-year construction work was particularly difficult because of the great distance from the coast. The railway line from the port to Cahllapata was 900 km long. From there, the building material was brought to the mine in two-wheeled wagons in five day trips. The carriage transport from the ore mill to the mountain station of the funicular took a day. The cement was brought to the construction site on llamas from the railroad. The llamas took seven days to get there and sometimes traveled for weeks, with much of the cement being lost along the way.

Decauville Railway

The construction material was transported from the valley station of the funicular railway to the dam on a Decauville railway with a gauge of 600 mm.

Narrow gauge railway

In order to reduce production costs, tin producer Simon Patirio built a winding, meter - gauge , narrow-gauge railway in 1923 that ran from Challapata to Llallagua. After the railway line went into operation, Llallagua doubled its exports from 15,500 tons in 1924 to 33,400 tons in 1929, which then accounted for 38% of total national tin production. The railway has since been shut down, but some of its listed freight wagons have survived.

marketing

After three years of investing in the construction of this dam, and the dam had just started supplying the Llallagua Tin Mining Co. with cheap electricity, the company that marketed the tin became embroiled in the First World War . Although the United States required most of the world's tin production at the time, there was no one in America at the time who wanted to buy and smelt the Bolivian tin concentrates. The Americans talked loudly about trying to meet the needs of South America, but they forgot that the main need was a market for nitrates, tin, copper, silver, rubber, cotton and all the different products of the South American countries.

Individual evidence

- ^ Luis Oporto Ordóñez: Llallagua: La ciudad del Estaño.

- ↑ a b c d e f Mark. R. Lamb Llalluga Dam - Hydro-Electric Plant at a Bolivian Tin Mine (The Engineering & Mining Journal, Jan 2, 1915)

- ↑ Fragmented State Capacity: External Dependencies, Subnational Actors, and Local Public Services in Bolivia. 2019. p. 161.