Englishman (tool)

An Englishman , also a universal wrench or universal wrench , is an adjustment key for loosening and tightening hexagonal screw connections. Regionally adjustable wrenches of this type are also called "Hesse" or otherwise. The term “Englishman” is often used incorrectly for the adjustable wrench and for other tools.

The distance between the clamping jaws can be continuously adjusted by turning a threaded spindle in the tool shank. He may look like a fork wrench for hexagonal and square nuts are used by the adjustability for fastening means according to the metric , imperial and proprietary (works) standards.

Classification and history

English is the colloquial term for all types of adjustable wrenches , especially those with a single jaw (as opposed to the French with double jaws ). In the narrower sense, the Englishman is an adjustable wrench in which the adjustment of the width across flats is carried out via a threaded spindle in the tool shank. In contrast, most of the adjustable wrenches in use today are adjusted via a worm gear in the wrench head (see Fig. 3). The correct term for such tools is adjustable wrench , also known as adjusting wrench .

The so-called Franzose has a similar area of application , in which the wrench size is changed via the interaction of a right-hand and left-hand threaded spindle by turning the tool shaft.

Since the jaws of the English and the adjustable wrench are only available on one side, they offer advantages over the French in confined spaces. In terms of durability and quality over many years, open-ended spanners and ring spanners are superior to the English because there are no moving parts. However, adjustable wrenches can also be used for (hexagon) screws for which no suitable wrench is available. Thus, the Englishman is not a competition to open-end or ring spanners, but a completion of the workshop equipment.

The origin is likely to lie in the fact that in pre-industrial times screws and nuts were paired forged parts and the screw heads therefore did not have uniform dimensions. In the early industrial era, nuts and bolts were not standardized; many manufacturers produced these themselves and were therefore subject to proprietary factory standards.

It is assumed that the origin of the term “Englishman” was that in workshops this tool was used for reasons of cost for the imperial (read English; see also Joseph Whitworth ) screws and nuts, which are less common in continental Europe , if only metric open-end or ring spanners were available . In addition, the first adjustable keys of this type were probably also developed and manufactured in England.

It was further developed and patented (on May 11, 1892 under the patent number SE4066) by the Swede Johan Petter Johansson in his workshop Enköpings Mekaniska in Enköping , which he founded after he had invented the pipe wrench in 1886 . B. A. Hjört & Co. ( Bahco ) has been producing and marketing the tool all over the world since 1892.

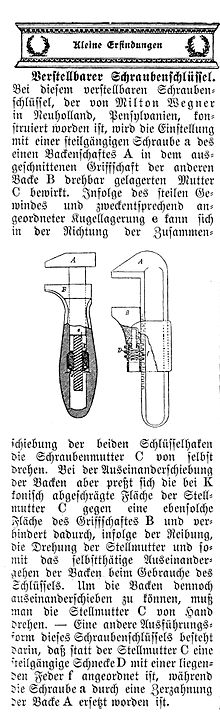

An adjustable wrench was also designed (before 1899) by Milton Wegner of New Holland, Pennsylvania.

handling

Improper handling of the English tool often leads to increased wear or deformation of the tool. If an Englishman of the type shown in the picture is to be used to loosen or tighten screws or nuts, make sure that the moving part of the jaw or fork always points in the direction of the rotary movement to be performed. Otherwise, the movable side of the fork or the adjustment mechanism can permanently deform and, as a result, have increased play or even become unusable.

While the key is already on the workpiece, the adjustment mechanism is readjusted by gently moving it back and forth. In this way, the closest possible fit is achieved. If the fork width is not chosen narrow enough, this can lead to sliding off the polygon. On the one hand, the screw or nut can give way permanently due to the inadmissibly high edge pressure and thus be "turned round"; loosening or tightening becomes more and more difficult. On the other hand, when slipping, especially when using high physical strength, the risk of injury is great and the tool itself is exposed to too great a load.

An adjustable wrench that cannot be kept under tension like pliers during use or that automatically retighten, should only be used to counter-hold and not to force screws or nuts, as a really tight fit cannot be achieved here.

Picture gallery

Swedish road sign for roadside assistance

Image 3: A continuously adjustable adjustable wrench , erroneously called English

A pipe wrench that works in a similar way to an infinitely adjustable English wrench , but which is automatically clamped by the actuation force and has toothed jaws.

Web links

Individual evidence

- ↑ described and illustrated in: Mother Earth. Technology, travel and useful observation of nature in the home and family. First volume. W. Spamer, Berlin and Stuttgart 1899, p. 117