file

Files are multi-edged cutting tools for processing workpieces by removing material. The manufacturing process is called filing .

File blanks are forged from alloyed tool steel. The teeth are carved or milled into the file blade as continuous lines. Hewn teeth usually have a negative rake angle , the material is removed by scraping. Milled teeth have a positive rake angle, which means that they cut into the material. The teeth are often cut in a cross pattern so that the chips can be broken more easily. The linear serration distinguishes the file from the rasp , which has individual teeth.

The file is a classic hand tool. A distinction is made between files according to shape, cut and area of application.

Files are used in particular in mechanical engineering , tool making , mold and model making , for trimming workpieces, as well as for sharpening and deburring.

Only special files can be used for processing hardened steel , such as those with a diamond coating.

construction

The file blade is serrated on one or more sides and usually merges with the file tang at one end . Traditionally, the file tang is not hardened and tapers to a spike in order to be able to open a handle there, which is usually made of wood or plastic and is also called a file handle . To avoid splitting the wood during the driving of the Angel, the perforated end of this issue is often by a metal sleeve with waistband includes the ferrule is called.

The hewn or milled file blank is hardened . The tang is either not hardened at the same time or is then soft annealed again by heating in order to give it a certain elasticity .

File types

In descending order of size and length, a distinction is made between arm, hand, key and needle files.

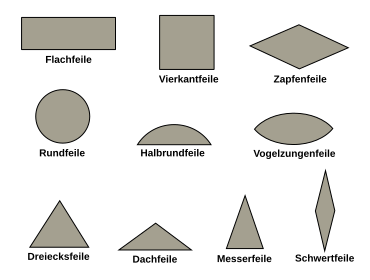

According to the shape of the cross-section one differentiates:

- Beret files

- Roof file

- Triangular file

- Triangular files

- Flat files / flat-end files

- Flat point files

- Half-round files

- Wedge Path Files

- Knife files

- Round files

- Sword files

- Square files

- Bird's tongue files

- Tenon file

- Oak file

Diamond files are also suitable for processing hardened steels. They have neither cut nor teeth, but are galvanically coated with diamond particles of different grains like abrasives .

To rework damaged threads using Thread Files .

Shoemaker's rasps are made with rounded ends and edges and can be handled with one or two bare hands.

Slash

The line-shaped notches on the file blade are called the cut. So that the chips can flow away, the cut is usually inclined or curved to the file axis. According to the type of cut, a distinction is made between single cut , cross cut and rasp cut .

The single cut can run across the file blade, slightly at an angle or in a curve. The single-cut form is mainly used for machining soft materials and for sharpening tools.

With a cross cut, the notches cross at an acute angle . The first cut is referred to as the lower cut, the second as the upper cut. The teeth of the lower cut are usually cut closer together and deeper than the upper cut. Since the top and bottom cuts are not parallel to each other, there are (irregularly) offset diamond-shaped teeth, which break the chip and counteract the formation of scoring . The cross cut is more suitable for working harder materials such as ferrous metals, but not for hardened materials.

When using a rasp to work on soft and fibrous materials such as leather and wood, the teeth sit individually on the file blade.

Milled files are usually made with a curved or angled single cut. Helical files usually have chipbreaker grooves built into them. Their area of application is similar to that of the rasp.

Number and number of cuts

| Cut number | designation | Hit count |

|---|---|---|

| 0 | Coarse file | 4.5-10 |

| 1 | Roughing file | 5.3-16 |

| 2 | Semi-plain file | 10-25 |

| 3 | Plain file | 14-35 |

| 4th | Double finishing file | 25-50 |

| 5 | Fine finishing file | 40-71 |

The number of cuts is the number of cuts per centimeter in the longitudinal direction of the file blade, in the case of rasps the number of teeth per square centimeter.

The cut number divides the possible number of cuts into areas that are standardized according to DIN 8349, taking the file length into account . This dependency means that files with the same cut number, regardless of length, always have the same number of cuts over the length of the blade. Accordingly, short files have a finer cut than long files with the same cut number.

The cut number is often imprinted on the file just above the tang.

Machinist's files with cut numbers 1 to 4 are often used. Precision applications require finer divisions up to cut 8 or even cut 10, which corresponds to 10,000 cuts for a file length of 200 mm.

Rasps are made with cut numbers 1, 3 and 5

Milled files are divided into coarse, medium and fine according to teeth 1, 2 and 3.

handling

The file blade usually ends in a square, pointed mandrel that is punched into a matching, pre-drilled hole in the handle.

Files for coarse use are firmly attached to a wooden handle by heating the pointed end of the tang until a red glow can just be noticed. The file blade is then used to firing beaten in the wooden handle into the hole.

Sensitive files and files with a hardened tang are not heated, but simply put into the wooden handle. Without the use of a hammer, the file is then driven into the handle simply by the flywheel of the file blade by striking the handle.

Round handles allow an individual hand position. Plastic handles often have a rectangular-oval cross-section that gives a feel for the orientation of the file.

Flat files are also offered without tang and handle in order to be able to finish larger surfaces. A slight crown or conicity in the front third of most files also allows small areas to be machined at specific points.

Small files such as key files are often not used with a separate handle, but instead have molded-on leaf-shaped gripping surfaces that are often used with a plastic coating (e.g. shrink tubing).

As a rule, the grid of the cross cut should not run in lines that run exactly lengthwise or across the blade of the file, so that no grooves form in the material when filing. When guiding the file in the right hand, the blade should be gently grazed to the right in order to achieve an even finish. With coarse files, it is also advisable to change the directions of movement.

Machine files are usually clamped in holders at both unmachined ends.

Files with milled teeth and a positive rake angle are often used to machine soft material, as they cut the material instead of scraping it. If used with hard material, these teeth would wear out too quickly. Even if the teeth become clogged with the removed material when machining light metal, a light metal file with a negative rake angle should be used.

A brass brush or a special file brush with short and slightly angled wires can be used to clean a file. Stubborn dirt can be scraped off the teeth with a metal strip. In order to prevent the processed surface from being scratched by particles stuck in the teeth, the file can be coated with whiting chalk or blackboard chalk . The chalk is brushed out and renewed regularly.

A dull file can be recognized by the shiny tooth surface when looking into the light. Inadvertent machining of hardened steel components also results in blunt, bright surfaces on the surface of the file.

The hardness of a material can be determined by stroking it with the untoothed side of a file. If the area of the file is rubbed bare as a result, the material is too hard to work with this file.

See also

literature

- Rolf-Dieter Blumer, Markus Numberger, Lisa Masen: The historic Burr file grinder in Königsbronn. On the history of an industrial museum in the Brenz valley . In: Monument Preservation in Baden-Württemberg , 42nd year 2014, issue 1, pp. 39–41, ub.uni-heidelberg.de (PDF)