Porcelain stoneware

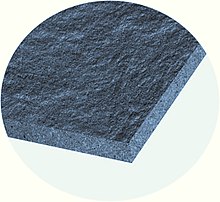

Porcelain stoneware , also called Böttger stoneware , is a commonly used but not normatively described term for ceramic tiles with very low water absorption but also for figures and vessels. They are usually used unglazed, especially as floor tiles, but are also offered glazed and polished .

properties

It is a very compact product that is sintered through due to the high firing temperature , the main feature of which is its low porosity with a water absorption of <0.5%. Due to the low water absorption, porcelain stoneware is frost-resistant and can therefore also be used outdoors.

Unglazed porcelain stoneware has very good abrasion resistance and high breaking strength. This makes it ideal for areas with intensive use such as stairs, corridors and industrial plants. The appearance and surface structure of unglazed porcelain stoneware can be influenced by colored ceramic powder or soluble salts sprinkled on before firing. Compared to glazed ceramic, however, the design options are limited.

Glazed and printed porcelain stoneware offers a wide variety of decors. Floor coverings made of natural stone and wood, as well as textile surfaces, cork, leather etc. are increasingly being imitated. Properties such as chemical resistance, slip resistance and scratch hardness can vary greatly depending on the type of surface.

history

As Boettger stoneware or Jaspisporzellan is the 1706 of Johann Friedrich Bottger and Ehrenfried Walther von Tschirnhaus invented "fine red Porcelain designated" (reddish brown stoneware). Initially, crockery and luxury items were made from Böttger stoneware in Meissen, but this was abandoned after a few decades. The name "Böttger stoneware" is today a protected brand name of the Meißner manufactory .

Today's porcelain stoneware consists of the three - as pure as possible - basic materials clay, feldspar and sand. With an approximate mixing ratio of 40, 40 and 20 percent, these form the main elements of the industrially manufactured porcelain stoneware. A firing process developed in Italy (rapid firing roller kiln process) made the production of fine stoneware tiles profitable from around 1980. The porcelain stoneware tile has since achieved an important market position in the field of tile and flooring materials.

Colors and shapes

In contrast to glazed tiles, porcelain stoneware is usually "colored through". The tile body has the color that results from the raw materials used and the addition of pigments to the body . To structure the surface, certain ingredients can either be evenly distributed or added in granular form. Usually the body is fine-grained and homogeneous and no heterogeneous elements (grains, inclusions, pores) are visible to the naked eye .

The surface can be monochrome, speckled, marbled or decorated in any other way. The edges are even and well finished. The currently predominant shape is rectangular (mostly 30/60 cm or larger), square (from 30/30, often also 60/60) and usually 10 to 14 mm thick.

Due to the firing process, traditionally manufactured tiles usually have slightly rounded edges and certain dimensional deviations and are intended for laying with joint widths of around 5 mm (in the range from 3 to 8 mm). In order to achieve narrower joint widths without the dimensional deviations becoming unpleasant, tiles are pre-sorted in the factory. Assorted tiles usually have dimensional deviations of less than ± 0.7 mm and are marked on the packaging with the information “calibrated” or “cal.” And the exact dimension or with a code number. If the joint width is narrow, calibrated tiles with different codes should not be laid together.

Porcelain stoneware tiles are also offered as "rectified". Rectified tiles were cut to size after the fire and therefore have sharp and precisely right-angled edges. Due to the precise external dimensions, the joint width can be reduced to 1.5 to 2 mm. Due to the sharp-cut edges, however, differences in height between the panels are clearly noticeable, so that particular care is required when laying.

Often special parts such as step tiles, step edges and skirting boards are offered.

Surface design

Porcelain stoneware tiles can be used untreated as they come out of the oven. Special effects can be achieved through glazes. In contrast to earthenware and stoneware tiles, the glaze on porcelain stoneware does not offer any great advantages in terms of durability and care of the surface.

Alternatively, the surface and edges can be sanded and polished or satinised after firing. As a result, however, the press and fire-related pore spaces are abraded and opened, which can lead to increased dirt adhesion. Most manufacturers of polished DSC recommend impregnating the surface with a silane - siloxane polymer mixture or other means. Since, in contrast to most mineral building materials such as ( lime ) sandstone , bricks , screed and normal concrete, porcelain stoneware has no capillary pore spaces, the impregnation is only used to fill the open pores on the surface. The disadvantage is that the impregnating agent makes it easier for organic dirt to adhere (soot in rubber soles or tires). This contamination can usually only be removed with solvents that also remove the silicone resins. In commercial areas, the impregnation even threatens to lose the set slip resistance .

The surface of the tiles can be modeled on the structure of natural stone . For defined anti-slip properties, hard material or diamond particles are sprinkled on and burned in or patterns and reliefs are embossed.

use

Due to the hardness and durability, the low thickness of the panels and the diverse design options in colors and formats, porcelain stoneware tiles are an easy-care alternative to natural stone or other floor coverings.

A disadvantage could be that due to the hardness and low strength, in contrast to natural or artificial stone, it is not possible to renovate the slabs by removing the surface. The panels usually have to be completely removed or covered with a new covering.

Large formats are increasingly being used that are up to 125 × 300 cm in size and can be used as wall-high elements in showers and bathrooms. It can also be used as a durable alternative to natural stone or metal facades, although the application limits of the facade DIN 18516 must be observed.

Porcelain stoneware is also used as a covering for kitchen work surfaces and washbasins in bathrooms.

Mosaic and border systems consist of pre-cut parts that are put together in the factory by machine or manually on a net so that they can be laid quickly and easily on the construction site. This can create complex surfaces. In wet rooms and kitchens, the small individual pieces result in a non-slip floor covering that can be easily laid on a slope and adapted to local conditions. When laying in showers , the use of a shower tray is not necessary.

Due to its frost resistance, porcelain stoneware is also used in gardening and landscaping for the design of terraces, paths and driveways.

Norms

The properties of porcelain stoneware are defined in standard EN 14411, group BIa (dry-pressed ceramic tiles with low water absorption E <0.5%).

literature

- State Porcelain Manufactory Meissen (Ed.): Böttger stoneware. A Meissen fascination sandstone publishing house, Dresden 2007, ISBN 978-3-940319-22-7 .

- Porcelain collection of the Staatliche Kunstsammlungen Dresden (Ed.): "Sächsisch schwartz lacquirtes Porcelain". The black glazed Böttger stoneware in the holdings of the Dresden Porzellansammlung Sandstein Verlag, Dresden 2013, ISBN 978-3-95498-033-8 .

- Bernd Ullrich, Albrecht Mields: The state of knowledge and newer findings on the European porcelain invention part 1 and 2, Keram. Ztschr. 55 (2003) [12] and 56 (2004)

- Ernst Zimmermann: The Invention and Early Period of Meissen Porcelain , Verlag Georg Reimer Berlin 1908, Reprint: Berlin 1978

- Albrecht Mields: On the dating of the European porcelain invention, cfi / Ber. DKG 87 (2010)

- Hans-Joachim Böttcher: Ehrenfried Walther von Tschirnhaus - the admired, fought and hushed genius . Dresden 2014. ISBN 978-3-941757-42-4 .

Individual evidence

- ↑ Figures and vessels made of porcelain stoneware , accessed on October 16, 2018.

- ↑ a b Factory visit: From raw materials to porcelain stoneware tiles. In: dear-magazin.de. March 31, 2017, accessed August 6, 2018 .

- ↑ Explanation of the tile label. In: hornbach.de. Retrieved August 6, 2018 .

- ↑ Anna Hoffmann / Fliesenhandel24: Tiles calibrated or rectified? What's the difference? In: fliesenaktuell.de. November 27, 2014, accessed August 6, 2018 .

- ↑ calibration. In: baunetzwissen.de. Retrieved August 6, 2018 .

- ↑ Maitreya Dittmers / jonastone GmbH & Co. KG: What do rectified and calibrated tiles mean? In: jonastone.de. Retrieved August 6, 2018 .