Dechen pit

| Dechen pit | |||

|---|---|---|---|

| General information about the mine | |||

| Remnants of shaft I. | |||

| Mining technology | Underground mining | ||

| Funding / year | up to 800,000 tons of t | ||

| Information about the mining company | |||

| Employees | up to 2,040 | ||

| Start of operation | 1854 | ||

| End of operation | 1964 | ||

| Funded raw materials | |||

| Degradation of | Hard coal | ||

| Geographical location | |||

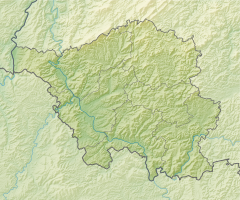

| Coordinates | 49 ° 20 '3.5 " N , 7 ° 8' 44.5" E | ||

|

|||

| Location | Heinitz | ||

| local community | Neunkirchen / Saar | ||

| District ( NUTS3 ) | Neunkirchen | ||

| country | State of Saarland | ||

| Country | Germany | ||

| District | Saar | ||

The Dechen mine ( ) was a coal mine in the Heinitz district of the Saarland community of Neunkirchen / Saar .

history

The good production results of the Heinitz mine led to considerations in 1853 to create a new production site between the Heinitz and König mines . In 1854, the sinking work for the first of these "middle shafts" began in Holzhauertal , and the second shaft was dug two years later. In 1855 the new shaft location became independent and named after the director of the Bonn Mining Authority, Chief Mining Officer Heinrich von Dechen (1800–1889). In 1856 the mine was connected to the Neunkirchen – Heinitz railway line . The Dechen III shaft was excavated the following year. For the first time in the Saar district , an iron shaft was built with rings made of double angle iron and T-beams. Sleeping sheds and Steiger apartments, a forge, a colliery and an office for officials were built. The production developed extremely well in the following period - despite strong water inflows, which repeatedly impeded work on the plant. Above all, the sought-after coking coal was mined.

In the 1930s the mine was modernized and the daytime facilities were renewed between 1936 and 1939. The rack conveyor at the main Dechen II shaft was replaced by a 7.5 t container conveyor . In 1937 the air supply was switched from compressed air to a shared compressor system at the Heinitz mine. In addition, the timber construction was replaced to a large extent by an iron track extension, which consisted of three-part double-T track frames with flange connections, specially developed with the Saarhütten. The hanging slides have been replaced by roller slides. The benzene locomotives used in mainline transport were replaced by diesel locomotives. In 1938 the Dechen mine reached the highest production rate: 2,040 employees extracted around 800,000 tons of hard coal. In 1939 a cable car was put into operation to transport the raw washed coal to the König daily facility.

After the end of the Second World War , the end of the mine became apparent. On January 1, 1963, the Dechen mine was subordinated to the König operations management and the routes to the underground network of the two mines were set. The breakthrough occurred as early as August 19, 1963. To extract the coal from the field of the former Dechen mine, the Wilhelm shaft II of the König mine was sunk down to the seventh level and rebuilt. The shaft reached its final depth in mid-July 1963. In 1963 the Dechen mine employed a total of 1,746 people and had an annual output of 629,048 tons. On January 1, 1964, the Dechen mine was merged with the König mine to form the König-Dechen composite mine. In 1968 the funding was stopped.

In the 1970s, the daytime facilities with the headframes were demolished. Partly a fallow land was created here, which was later converted into an industrial area. In 2013, a photovoltaic system was installed on the 2.5 hectare former coal storage area in the west .

literature

- Karl-Heinz Ruth: Dechen mine . (= Tunnels and shafts in hard coal mining on the Saar , Volume 25), Saarbergwerke, Saarbrücken 2000

Web links

- The Heinitz mine , saarlandbilder.net