Hamon

Hamon ( Japanese 刃 文 ) is the visible hardness zone on Japanese sword , knife and lance blades .

description

The Hamon (Japanese nouns have no gender. The HAMON is usually said) is the most important visible, aesthetic element on Japanese blades. Every master swordsmith shows with the hamon a kind of signature as well as his technical ability. The fine design is also a mark of the quality of the forging work. Many experts recognize the blacksmith who made the blade by the shape of the hamon . Often the design was dependent on school, time or fashion.

The finished forged and not yet hardened blade is coated with a mixture of clay , water, finely ground grindstone and charcoal powder. The cutting area (Ha) is only very thinly covered with the clay mixture. The side and the back of the blade ( mune ) are coated thicker with the mixture. In the later hamon area, fine transverse lines from the clay mixture are applied to influence the shape of the hamon. After drying, the blade is reheated with the clay until it is red-hot. The blacksmith can tell the correct temperature (around 800 ° C) by the color of the red-hot steel. The blade is removed from the forge at the right time and quickly cooled in a water bath. The clay coating, which is only thinly available on the cutting edge, cools it down very quickly, while, due to the thicker layer of clay on the side and back, these areas cool down a little more slowly. On the cutting edge, the very rapid cooling creates a hardness configuration in the steel ( austenite is converted into martensite , a mixture of martensite and pearlite is created ). This structure is visible and is called "Nie" or "Nioi" "in connection with Japanese sword blades. Quenching in water hardens the steel. At the cutting edge there is a hardness of about 60 HRC (HRC = Rockwell hardness ), on the back about 40 HRC. After the hardening process, the hamon area is particularly emphasized by grinding and special polishing of the blade by a specialist (Togishi). This also makes the structure of the steel ( Hada ) visible. The presence of a hamon is not an indication of Blades made of a single type of steel (monosteel) (Maru) can also be equipped with a hamon , as can a laminated blade made of several types of steel (Sanmai, Kobuse, Waharia Tetsu or Soshu Kitae).

Special formations in the hamon (e.g. ASHI) also have a practical purpose: They are intended to prevent a crack, which can arise in the event of damage, from running into the not so hard area of the blade. This is ensured by the more elastic areas in the blade. Should a crack develop in the cutting edge (HAGIRE), the blade would be lost. The structure of the hamon is not limited to the surface, it is also present inside the blade, but in a reduced form depending on the hardening depth.

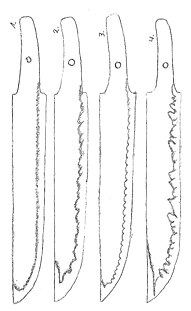

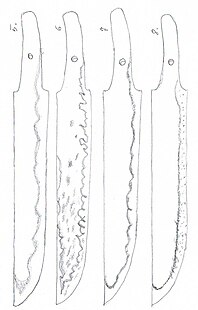

There are different forms of hamon , which are named as follows:

- Suguha

- Suguha-ashi

- Gunome

- Small gunome

- Irregular Gunome

- Slanted Choji

- Toran

- Hitatsura-Choji

- Co-notaries

- Midare

- Toran

- Gunome Togare

Some of the versions named here are the basic types. These can be combined to form other types (e.g. Gunome Midare). This results in many other versions:

- Sanbonsugi - Three cedars

- Kikusui - chrysanthemum on water

- Hako - box-shaped

- Yahazu - notches

- Mimigata - ears

etc.

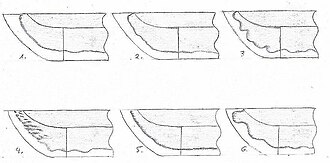

Hamon des Boshi

The boshi is the hardened part of the blade tip ( kissaki ). Hardening with clay results in a sometimes different course of the hamon , which is named differently from the hamon on the blade edge. These terms are as follows:

- Komaru , "Small Circle".

- Ōmaru , "large circle".

- Midare-Komi , "irregularly wavy"

- Hakikake , "brushstroke"

- Yakizume , "No turning back"

- Jizō , "shaped like Jizō's head"

Modern versions

Since the production of clay-hardened blades is time-consuming and difficult (see also differential hardening), a hamon is sometimes forged on modern blades. It is produced by grinding , brushing with metal brushes or by etching with various acids. Some modern swords use steels which, due to their properties, cannot be differentially hardened or for which clay hardening would not make sense. In these cases a fake Hamon is used. Many fakes from the Far East are offered as genuine Hamons, which is usually difficult for laypeople to distinguish. Fraudsters have an easy time of it.

Individual evidence

- ↑ Kōkan Nagayama: The connoisseur's book of Japanese swords. Kodansha International, Tokyo et al. 1997, ISBN 4-7700-2071-6 , pp. 38-39.

- ↑ Website of the company Cheness, producer of sword blades made of modern high-performance steels, (accessed on November 12, 2010)

literature

- John M. Yumoto: The samurai sword. A handbook. Tuttle Publishing, Rutland VT 1989, ISBN 0-8048-0509-1 .

- Nobuo Ogasawara: Japanese swords (= Color Books. 22). 12th edition. Hoikusha, Osaka 1993, ISBN 4-586-54022-2 .

- Leon Kapp, Hiroko Kapp, Yoshindo Yoshihara: Japanese swordsmithing. Ordonnanz-Verlag, Eschershausen 1996, ISBN 3-931425-01-0 .

- Clive Sinclaire: Samurai. The Weapons and Spirit of the Japanese Warrior. Lyons Press, Guilford CT 2004, ISBN 1-58574-282-1 .

- Victor Harris: Cutting Edge. Japanese Swords in the British Museum. Tuttle Publishing, North Clarendon VT 2005, ISBN 0-8048-3680-9 .