Ratschach wooden railway

| Ratschach wooden railway | |

|---|---|

|

Carriage and superstructure of the Ratschach wooden railway

| |

|

Location of the old castle near Ratschach

| |

| Route length: | 4,171 km |

| Gauge : | 848 mm |

| Maximum slope : | 55 ‰ |

| Minimum radius : | 19-47 m |

The wooden railway Ratschach (historical name: "Wooden railway on the Löwenfeld'schen Herrschaft Ratschach in Krain ") was a narrow-gauge forest railway with wooden rails near Radeče in Slovenia , which was operated from 1869 to 1874.

history

The forest railway was built to transport the beech forest to be felled in the Jatna district on an existing forest path. The laying of the railroad tracks was started in 1869 and carried out within a short time. It operated until October 1874.

Since the railway was only to be used for a short time, it was made as simply and cheaply as possible. The entire superstructure was constructed from beech wood. Half-round timbers with a diameter of 237–263 mm and a length of 1½ meters were used as basic sleepers. Either half-cut round timber, which was then cut on two sides, or whole round timber with a small diameter, which were processed into beams 3.80 m long and 132 × 132 mm, were used as long sleepers. Long sleepers made from quarters of round timber, on the other hand, proved to be unsuitable because they warped strongly within a short time.

Route

The total length of the track was 4,171.2 meters. The railway crossed a stream in 5 places, whereby the long sleepers were simply placed on posts. The gradient of the railway ranged between 21 and 55 ‰ and averaged 34 ‰. The arches had a minimum radius of 19 to 47 m, with the outer rail being raised by 26 mm. The switches were made in a very simple way using the old switch system.

Track construction and maintenance

The long sleepers, with a track width of 848 mm, were attached to the cross sleepers 1.30 m apart with oak nails so that their upper, flat surface was slightly inclined towards the axis of the track. The long sleepers were connected to each other at the joints by connecting straps.

Rails 45.9 mm wide and 4.4 mm thick were attached to the inner edge of the long sleeper with conical-headed, forged nails. The experiment with wood screws gave an unfavorable result. An expansion gap of 13 mm was provided at the rail joints.

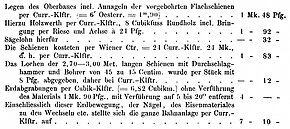

The cost of the railway production of the entire railway system, which was carried out in piecework , including the earth moving, the nails, the iron material for the switches, etc. amounted to 3.73 marks per meter (7.19 marks per Curr. – Klftr.)

The wear and tear on the track was most noticeable and quickest in the arches and switches. The rails were often torn off. Therefore a railway supervisor, who also took care of the railway maintenance, had to be employed.

The annual rail maintenance costs were 32–53 Pfennig per meter (60–100 Pfg. Per curr. Class).

dare

The railway wagons were supplied by the Körösi factory in Graz and later manufactured in-house. The piece cost 192 marks. The wagons built by the forestry office themselves weren't cheaper either. The wheelbase of the first car was 1.50 m, which in practice proved to be inadmissible.

The forged axles with a diameter of 53-66 mm wore firmly keyed cast-on cast wheels with a diameter of 316-395 mm. The frames were first made of larch wood, which, however, did not work, and was later made of oak.

The weight of an unloaded wagon with belt and coupling chains was 350 kg (7 cents). The rail cars have a load capacity of 3.5 t (70 Ctr.), But were only loaded with a maximum of 2 tons.

business

The entire railway was set up for downward transport, as it ran with the gradient mentioned above in a valley basin along a stream.

So you didn't need a motor downhill. A brakeman drove on each wagon who was rewarded with 1 Mk. 40 Pfg. In winter and 1 Mk. 68 Pfg. In summer and who at the same time assisted in loading and unloading wood. The loaded blocks of wood were piled up between the heads to a height of 1.60 m and held together with chains in the middle. The return of the empty wagons was done by horses, one of which pulled 3 wagons on the smaller slopes, but only two or even one on the larger ones.

According to a report, the resilience of the cars was not satisfactory. The breaking of the treads, as well as the jumping of the wheel center, happened relatively often, while the wheel flange proved to be quite safe. On the steepest slope, black ice had to be sanded in winter.

In the time from 5 a.m. to 6 p.m., the route was repeated 6 times in batches of 6 rail cars. The return transport of the empty wagons was awarded in the Accord with 6 Mk. By horse. The main cargo was logs, but logs and charcoal were also carried.

The lifespan of the cross sleepers, some of which were in the ground, was shorter than that of the long sleepers. The former became unusable in the third year.

One difficulty was maintaining the balance of the load with long timber given the small wheelbase of the wagons.

The builder of this wooden railway was the Löwenfeld forest master Moritz Scheyer. He was of the opinion that if a similar system was repeated, it would be advisable to widen the running surface of the wheel, whereby one could even dispense with the flat rails, with whose performance he was not satisfied anyway.

See also

Individual evidence

- ↑ a b c d e Edmund Heusinger von Waldegg : Manual for special railway technology. 1878. Fifth volume, pp. 533-534 (see also reprint from 2020. ISBN 978-3-84604-840-5 ).

- ^ WF Exner: Modern transport in the service of agriculture and forestry. Weimar 1877.

- ↑ Alexander von Engel: Austria's wood industry and wood trade: A monograph. 1907, p. 150.

Coordinates: 46 ° 4 ′ 5.8 " N , 15 ° 10 ′ 53.4" E