Twill weave

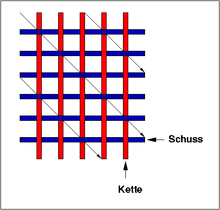

The twill weave (also known as twill or twill for short ) is one of the three basic weave types for woven fabrics , alongside the plain weave and the satin weave . Twill weaves can be recognized by the sloping ridge . The best-known fabric in twill weave is the denim , the blue and white denim . If the ridge runs from top left to bottom right, one speaks of an S-ridge body; if it runs from the bottom left to the top right, it is a Z-ridge body, corresponding to the orientation of the middle part of the two letters.

A distinction is also made between warp and weft, depending on whether the warp or weft threads predominate at the top. When weaving on the machine or loom, the weaver calls the upper side the “right product image”. The well-known denim, for example, is a warp twill: the warp is blue, the weft is white. On the loom , denim is woven with the bluer side on top. In order to protect the mechanics of the loom, today denim is mostly woven with the "warp-heavy" side (in the above case the top of the fabric / the right fabric image / blue side) facing down. Furthermore, protection against soiling of the actual upper side of the goods in the weaving mill is achieved.

There are equally and unevenly woven variants of twill fabrics. Equally binding means that the fabric looks the same on both sides, technically speaking on the left and right side of the fabric.

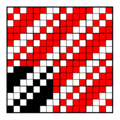

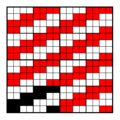

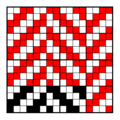

Binding cartridge for a warp twill

|

|||

Depending on the weave and thread density used, twill can be dense, smooth and durable, but also soft and loose.

There are a few variations and derivatives of the twill weave:

- Equal burr twill: Here the warp and weft threads are distributed evenly over the surface (the number of warp lifts and drops in the repeat is the same), which is why they are also referred to as equilateral. Except for the direction of the ridge, both sides of the goods are the same.

- Multi-burr twill have two burrs of different widths, they are available as warp, weft or equilateral twill.

- Broad burr bodies have very wide burrs, each consisting of at least two warp or weft lifts (warp lift = warp thread above, weft lift = weft thread above). There are equal-sided and unequal-sided broad-burr bodies.

- Steep ridge twill is created when a high warp density is used, among other things. They are characterized by the fact that their ridges, in contrast to most bodies (with about the same warp and weft density), do not run at an angle of 45 degrees.

- Flat ridge bodies are, so to speak, the opposite of steep ridge bodies. They have a high weft density and are therefore also weft bodies.

- Pointed ridge twill (also zigzag twill) is created by changing the ridge direction. A distinction is made between transverse and longitudinal pointed ridge twill as well as pointed check twill.

- Herringbone (also Gradl ) are formed by changing the ridge direction, wherein the change in contrast to Spitzgratköper the binding points to one or more shots are shifted.

- Cross twill do not show the typical ridges. They are created by halving the repeat in the warp or weft direction and at the same time changing the weave direction (between Z and S direction, analogous to the Z and S bodies)