Betz's law

The Betz law comes from the German physicist Albert Betz (1885-1968). He first formulated it in 1919. Seven years later, it appeared in his book Wind Energy and its Exploitation by Windmills . The British engineer Frederick W. Lanchester (1868–1946) published similar ideas as early as 1915.

The law states that a wind turbine can convert a maximum of 16/27 (almost 60 percent) of the mechanical power that the wind would transport through its projection surface (rotor surface, harvesting surface, active disk perpendicular to the wind direction) without the braking rotor. The reason is that the energy output is accompanied by a reduction in the flow velocity and an air jam, which allows part of the incoming air to escape from the rotor surface. In addition, complete removal of the energy would mean that the air would remain standing, which would correspond to a complete air stagnation. Therefore there is an optimum in terms of energy extraction and removal of the air that is slowed down as a result.

Variety of names

Because of this theoretical limitation, which the efficiency otherwise defined for machines does not have, Betz introduced the term quality factor for the quotient of the used to incoming wind power, c P = P / P 0 . In 1926 he called it the performance figure , today the term performance coefficient is common in specialist literature , but the harvest rate and efficiency are also common.

The designation "Betz's performance coefficient" is common both for the theoretical dependence of this quotient on the deceleration of the flow, as considered by Betz and explained in the following chapter, for its maximum value, and generally for the quality factor introduced by Betz for real wind turbines.

The term harvest factor has a different meaning as an economic key figure for the ratio of the amount of energy released by a wind power or solar installation during its service life to the amount of energy that was used to build it.

Derivation

The prerequisites that Betz assumed are:

- The wind turbine has no extension in the direction of flow , so it is a surface.

- The flow creates a negative jump in the pressure curve in this actuator surface A.

- The useful power P is taken from the flow without loss .

- The density of the medium is constant, i.e. incompressible flow and no heat flow between the flow and the wind turbine.

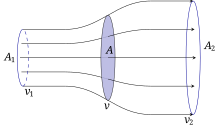

The pressure far in front of and far behind the system is the same, the negative pressure jump is compensated for by a gradual increase in pressure both before and after the effective surface. Associated with the increase in pressure is a deceleration of the flow from the initial speed v 1 via v in the effective area to v 2 far behind. In inverse proportion to the flow velocity, the cross-sectional area of the flow tube increases from A 1 to A to A 2 , see figure, because all of its cross-sections are traversed by the mass flow ( continuity equation ).

If, according to the law of conservation of energy, the extracted power P is equated with the difference between the kinetic energy flow associated with v 1 and v 2 , one obtains

- ; with as back pressure .

According to the theorem of Froude and Rankine is

The withdrawn power is then

- .

With the relative remaining speed (and therefore ) follows

- ; with A being the rotor area and the power density of the wind.

In relation to the incoming wind power , the power coefficient results from

- .

The course of the function is shown in the diagram on the right for x = 0.1 to 1, which roughly covers all real operating states that can be achieved.

x = 1 means v 2 = v 1 (and also v = v 1 ), i.e. no braking whatsoever, and consequently the power coefficient c P (1) = 0 means that no power is drawn. All three areas of the flow tube are the same in this case (specifically, A 1 : A = v : v 1 = 1 and A 2 : A = v : v 2 = 1). This operating state corresponds practically to the standstill of the rotor.

x = 0 means deceleration to v 2 = 0 and for v = v 1 /2 the power coefficient c P (0) = 0.5, where A 1 : A = v : v 1 = 0.5 is obtained. But because of the theoretically infinite value of the area ratio A 2 : A = v : v 2 (division by zero), this operating state is actually not possible.

x = 0.1 means v 2 = v 1 /10 and v = v 1 * 0.55 as well as A 1 : A = v : v 1 = 0.55. The line coefficient is c P (0.1) = 0.55 * 0.99 = 0.5445, i.e. just over 54%, as well as the area ratio A 2 : A = v : v 2 = 0.55: 0.1 = 5.5. The exit cross-section A 2 of the flow tube would in this case be 5.5 times larger than the rotor area - an operating state that is difficult to achieve and also not optimal in terms of the result.

The function reaches its maximum at x = 1/3, as can be shown by deriving it and setting it to zero (see calculation of minima and maxima ). That means and as well as A 1 : A = v : v 1 = . The remaining third of the flow evades the effective area. This 'loss' corresponds to the first term in 0.5926. The second term means that the flow through the effective surface 8/9 of its energy is withdrawn. Thus the maximum of the performance coefficient is approx. 0.5926, i.e. just under 60%. The area ratio A 2 : A = v : v 2 = 2/3: 1/3 = 2 means that the exit cross-section A 2 of the flow tube must be twice as large as the rotor area - this is the ideal operating state according to this law.

Other performance coefficients

It is often claimed that c P > c P (1/3) has been obtained. Within the assumptions of the model, however, this is as impossible as a violation of the conservation of energy or momentum. Complicated flows in the effective area, for example, only reduce the power coefficient if the effective area is broken down into small sub-areas: The above derivation applies to each individual corresponding flow tube, so that v = 2/3 v 1 must apply over the entire effective area in order to achieve the global optimum to reach.

Often an “over-bed value” is claimed for jacketed wind turbines. Although the Betz disk model does not cover these constructions, it does provide an explanation: The jacket, which acts as a diffuser, runs parallel to the narrower part of the Betz flow tube and allows the rotor to be shifted forwards so that it can be smaller. Since the jacket encloses the 'correct' reference surface (including that ), nothing is ultimately gained.

So far, only a theoretically possible solution is known which has already been specified by Betz itself: If the as a single, infinitely thin "active disc (engl." Actuator disk ) awarded a finite thickness modeled rotor so could transverse to the main flow existing turbulent fluctuations additional Introduce energy into the volume between the two active disks to be distinguished upstream and downstream. This idea was worked out in detail by Loth and McCoy in 1983 for a Darrieus rotor with a vertical axis of rotation. They got c P ≈ 0.62.

The officer, designer and inventor Kurt Bilau worked intensively on the development and improvement of streamlined wings after the First World War. After test models in the wind tunnel (small blade diameters less than one meter and correspondingly high speeds with speeds of over 1000 / min) still yielded the calculated and realistic efficiencies of 35-40% according to Betz's formula, large repellers with a diameter of 9 m on a test site the University of Oxford certified 91% efficiency with several measurement methods. Earlier measurements of two Bilauian repellers with a diameter of 17 m with somewhat more primitive measuring technology in East Prussia gave similar results (89 and 90%). This enormous degree of efficiency was explained by the different flow conditions that arise with the larger wing areas due to higher air inertia and the resulting eddies that pull and push the wings. The system tested in Oxford started up at a wind speed of less than 2 m / s and generated an output of 0.4 kW at 2.24 m / s. Their ideal wind speed was 3–8 m / s. In the test period from June 1924 to May 1925, this system is said to have performed a total of 10195 kWh of work. Nevertheless, it remains questionable whether it would be profitable to build such a repeller system, since the wings work with a relatively large area and high dynamic pressure, which requires a correspondingly massive material design.

The series of rotors also allows an increase in the value with respect to a rotor area, although the efficiency of the individual rotors decreases enormously due to drag vortices.

Executed rotors on horizontal axes

Rotors are constructed with the least possible use of material and thus low weight. In addition to the performance coefficient based on the rotor area (harvested area), there is also the performance coefficient based on the wing area and other factors that play an important role in the design of rotors. Because of the limited maximum wind load, a small total surface area of the rotor blades is desirable. That is why the profiling of modern rotor blades does not start in the inner hub area. There is a trend towards higher elongation and longer rotor blades with regard to tower height. Rotors achieve performance coefficients of c P = 0.4 to 0.5. So that's about 67% to 84% of what is theoretically possible. Slow runners and vertical axes, Darrieus rotors, H rotors etc. did not achieve such values.

literature

- Albert Betz : The maximum of the theoretically possible utilization of the wind by wind motors. Journal for the Entire Turbine Industry, Issue 26, 1920

- Albert Betz: Wind energy and its use by windmills. Vandenhoeck & Ruprecht, Göttingen 1926; Ökobuch Verlag, Staufen 1994, ISBN 3-922964-11-7 (unchanged reprint).

- Kurt Bilau : The use of wind for power generation. Published by Paul Partey, Berlin 1942.

- John L. Loth , Hugh McCoy : Optimization of Darrieus Turbines with an Upwind and Downwind Momentum Model. In: Journal of Energy. 7, 1983, pp. 313-318 ( PDF file ; accessed on March 28, 2016; English).

- Robert Mikkelsen : Actuator Disc Methods Applied to Wind Turbines. Dissertation at the Technical University of Denmark, 2003 ( PDF file ; accessed June 11, 2010; English).

- Derek Grant Phillips : An investigation on diffuser augmented wind turbine design. Dissertation at the University of Auckland, 2003 ( online ; accessed June 11, 2010; English).

- Dietrich Oeding , Bernd R. Oswald : Electrical power plants and networks (6th edition), Springer-Verlag, Berlin / Heidelberg 2004, ISBN 3-540-00863-2 , pp. 113–115 ( limited preview in Google book search) .

- Robert Gasch , Jochen Twele : Wind turbines. Basics, design, planning and operation. 8th edition, Springer, Wiesbaden 2013, ISBN 978-3-8351-0136-4 , pp. 194f.

- Alois P. Schaffarczyk : Introduction to Wind Turbine Aerodynamics. Springer, Berlin, 2014, ISBN 978-3-642-36408-2