The Nußeltsche water skin theory referred to by Wilhelm Nusselt presented in 1916 theory of heat transfer in the laminar film condensation on pipes and vertical or inclined walls. Due to the great technical importance of heat transfer through condensation processes , Nusselt's theory was corrected through numerous experiments and expanded by other authors to include the description of turbulent condensate films. Nusselt derived the formula for calculating the mean heat transfer coefficient of the condensate film for the heat transfer from the steam to the wall.

Basic principle of water skin

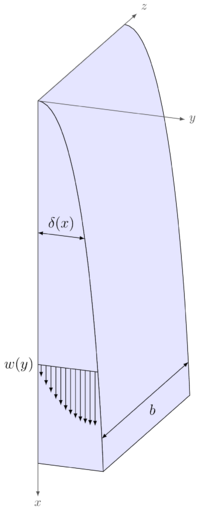

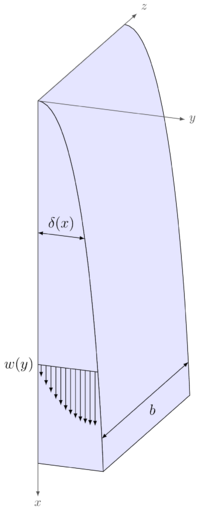

The basic assumption of Nusselt's theory is that the temperature gradient between steam and wall temperature is due to the condensate film (the water layer) that forms on the cold wall. It is also assumed that the convective heat transfer and radiation can be neglected within the thin condensate film and that only the heat conduction of the water is relevant for the heat transport to the wall. This means that the condensation of the steam only takes place on the surface of the condensate and only in an amount that corresponds to the amount of heat transported at this point. The growing condensate film flows downward under the force of gravity , the layer thickness steadily increasing. Assuming that a steady flow develops, the forces exerted by shear stresses are in equilibrium with gravity.

with , whereby in a Newtonian fluid ( a) parabolic velocity profile is emerging

Here, and the densities of water in liquid or gaseous phase, the dynamic viscosity of water, and the constants of integration and the distance from the wall. As a restriction, it should be mentioned that this equation only applies to small temperature differences, since the temperature dependence of the dynamic viscosity is neglected during integration. With the sticking condition of the water on the wall, the speed is at this point . So that is the constant . With static or slowly flowing steam, the speed difference between condensate and steam is so small that the shear stress of the steam on the surface of the condensate can be neglected.

-

schematic representation of the water skin on a wall

This is for

The mean speed over the film thickness is obtained from the integration

The condensate mass flow results across the width of

Based on the assumption that only the heat conduction in the condensate is considered, the transported heat flow results to

From the coupling of heat and mass flow via the evaporation enthalpy ( ), the differential equation of the layer thickness can be set up with the derivation of the mass flow, assuming constant thermal conductivity at the temperature difference under consideration .

If no condensate stream flows from above onto the observed surface, the constant of integration can be determined and the film thickness is determined by

![{\ displaystyle \ delta = \ left [{\ frac {4 \ lambda _ {\ rm {L}} \ eta _ {\ rm {L}} (\ vartheta _ {\ rm {s}} - \ vartheta _ { \ rm {0}})} {\ varrho _ {\ rm {L}} (\ varrho _ {\ rm {L}} - \ varrho _ {\ rm {G}}) g \ Delta h _ {\ rm { v}}}} x \ right] ^ {1/4}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/36906a22cb1a9ac73b84871254ba70038b4dc45c)

described. This means that the film thickness increases very strongly at first, then weaker and weaker over the height of the wall. The heat transfer coefficient at the height is given by

-

![{\ displaystyle \ alpha = {\ frac {\ lambda _ {\ rm {L}}} {\ delta}} = \ left [{\ frac {\ varrho _ {\ rm {L}} (\ varrho _ {\ rm {L}} - \ varrho _ {\ rm {G}}) g \ Delta h _ {\ rm {v}} \ lambda _ {\ rm {L}} ^ {3}} {4 \ eta _ {\ rm {L}} (\ vartheta _ {\ rm {s}} - \ vartheta _ {\ rm {0}})}} {\ frac {1} {x}} \ right] ^ {1/4}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/0cab11800421a568db67dfd5d56e8b76f591bb8e) .

.

The mean heat transfer coefficient is obtained from the integration over the height of the wall .

-

![{\ displaystyle \ alpha _ {\ rm {m}} = {\ frac {1} {H}} \ int _ {0} ^ {H} \ alpha \, {\ rm {d}} x = {\ frac {4} {3}} \ alpha (x = H) = {\ frac {4} {3}} \ left [{\ frac {\ varrho _ {\ rm {L}} (\ varrho _ {\ rm { L}} - \ varrho _ {\ rm {G}}) g \ Delta h _ {\ rm {v}} \ lambda _ {\ rm {L}} ^ {3}} {4 \ eta _ {\ rm { L}} (\ vartheta _ {\ rm {s}} - \ vartheta _ {\ rm {0}})}} {\ frac {1} {H}} \ right] ^ {1/4}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/f43856730573a8434d0b3b1d3126cf9977c52b4d)

The most important finding of this formula is the dependence of the heat transfer coefficient on the temperature difference between the steam and the wall. Nusselt thus shows that the heat transfer decreases with increasing temperature differences.

Adjustments for sloping walls and pipes

When looking at inclined walls, the gravitational acceleration must be replaced by the expression to take account of the angle of inclination . This results in the heat transfer coefficient or mean heat transfer coefficient

-

and

and

For vertical pipes, the wall width is to be set equal to the pipe circumference, assuming that the pipe diameter is large compared to the film thickness . Inclined pipes cannot be described by the present equations because the condensate film is not evenly distributed over the surface. However, Nusselt looked at the condensation behavior on horizontal pipes. Let the radius of the horizontal pipe and the angle that a ray forms with the perpendicular through the observed point on the surface. This forms the vertically acting part of the gravitational acceleration on the pipe surface and can be used in the condensate velocity analogously to . A differential equation for the film thickness depending on the angle is obtained from the coupling of heat and mass flow .

This results from forming

Nusselt solved the differential equation by integrating it graphically through planimetrization. However, a numerical solution gives more accurate results. Under the condition that no water drips on the pipe, the condensate film thickness at the point is

-

![{\ displaystyle \ delta = \ left [{\ frac {4} {3 \ sin (\ varphi) ^ {4/3}}} \ int {\ sqrt [{3}] {\ sin (\ varphi)}} \, {\ rm {d}} \ varphi \ right] ^ {1/4} \ left [{\ frac {\ lambda _ {\ rm {L}} 3 \ eta _ {\ rm {L}} r} {\ varrho _ {\ rm {L}} (\ varrho _ {\ rm {L}} - \ varrho _ {\ rm {G}}) g \ Delta h _ {\ rm {v}}}} (\ vartheta _ {\ rm {s}} - \ vartheta _ {\ rm {0}}) \ right] ^ {1/4}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/621827941b2d95421257e202352f924a5586792c)

With the definition of the heat transfer coefficient , the mean heat transfer coefficient can be determined by integration over the section under consideration . Averaged over the circumference, the heat transfer coefficient is thus

![{\ displaystyle \ left [\ alpha _ {\ rm {m}} \ right] _ {0} ^ {180} = 0 {,} 8057 \ left [{\ frac {2 \ varrho _ {\ rm {L} } (\ varrho _ {\ rm {L}} - \ varrho _ {\ rm {G}}) g \ Delta h _ {\ rm {v}} \ lambda _ {\ rm {L}} ^ {3}} {3 \ eta _ {\ rm {L}} (\ vartheta _ {\ rm {s}} - \ vartheta _ {\ rm {0}})}} {\ frac {1} {d}} \ right] ^ {1/4}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/a3e93a590d234bee80d487e77835914931282dbe)

The value is determined numerically and is more precise than the value originally determined by Nusselt . The comparison of the vertical and horizontal position of a pipe with the length and diameter shows that more condensate precipitates on a horizontal pipe of the same dimensions than in a vertical position.

![{\ displaystyle {\ frac {\ alpha _ {\ rm {m, horizontal}}} {\ alpha _ {\ rm {m}}}} = 0 {,} 772 \ left [{\ frac {H} {d }} \ right] ^ {1/4}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/8538808136b815bc97aa515ef5913e21590e8207)

With regard to the technical applications, Nusselt also considered the case of a pipe cascade. For a pipe to the dripping condensate of an overlying tube, the initial condition of the equation must be changed so that for the film thickness against run. As the film thickness increases over the number of tubes lying one above the other, the heat transfer deteriorates with the number of tubes. For the second pipe, Nusselt determined that the heat transfer is only 68% of the first pipe. A mean heat transfer coefficient for the pipe cascade can be passed through

determine.

Influence of the steam speed

The shear stress on the surface of the condensate must be taken into account for flowing vapors . This changes the integration constant of the speed profile to

The shear stress component is positive here if the steam and condensate stream flow in the same direction. For steam flowing upwards, the component is negative. In the case of a pipe flow, the shear stress distribution results from assuming an equilibrium of forces between pressure and friction forces

The pressure loss at the steam speed can be determined.

Analogous to the derivation for steam at rest, one obtains the extended equations for the mean velocity and the mass flow.

Furthermore, the energy balance gives an expression for the film thickness.

However, this only applies to steam flowing downwards, since the boundary condition only applies under this circumstance . When the steam flows upwards, the condensate flow is initially split up. Part of the condensate is discharged upwards with the steam flow, while another part of the condensate is discharged downwards by gravity. From a speed limit, the entire condensate is drained upwards and the Nusselt closed

![{\ displaystyle w _ {\ rm {G}} ^ {2}> {\ frac {4 \ varrho _ {\ rm {L}}} {\ zeta \ varrho _ {\ rm {G}}}} \ left [ {\ frac {12 \ lambda _ {\ rm {L}} \ eta _ {\ rm {L}} (\ vartheta _ {\ rm {s}} - \ vartheta _ {\ rm {0}})} { \ varrho _ {\ rm {L}} (\ varrho _ {\ rm {L}} - \ varrho _ {\ rm {G}}) g \ Delta h _ {\ rm {v}}}} \ right] ^ {1/4}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/ee0e38599ef92ad3ba23ceaad071bdc4ecd2f319)

has determined.

literature

- W. Nusselt: The surface condensation of water vapor. In: Journal of the German Association. Engineers. 60, 1916, pp. 541-546, 569-575.

- HD Baehr, K. Stephan: Heat and mass transfer. Volume 6, Springer, Berlin 1994, ISBN 3-540-64458-X .

Individual evidence

-

↑ a b H. D. Baehr, K. Stephan: Heat and mass transfer. Volume 6, Springer, Berlin 1994, pp. 418-422.

-

↑ W. Nusselt: The surface condensation of water vapor. In: Journal of the German Association. Engineers. Volume 60, 1916, pp. 569-575.

![{\ displaystyle \ delta = \ left [{\ frac {4 \ lambda _ {\ rm {L}} \ eta _ {\ rm {L}} (\ vartheta _ {\ rm {s}} - \ vartheta _ { \ rm {0}})} {\ varrho _ {\ rm {L}} (\ varrho _ {\ rm {L}} - \ varrho _ {\ rm {G}}) g \ Delta h _ {\ rm { v}}}} x \ right] ^ {1/4}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/36906a22cb1a9ac73b84871254ba70038b4dc45c)

![{\ displaystyle \ alpha = {\ frac {\ lambda _ {\ rm {L}}} {\ delta}} = \ left [{\ frac {\ varrho _ {\ rm {L}} (\ varrho _ {\ rm {L}} - \ varrho _ {\ rm {G}}) g \ Delta h _ {\ rm {v}} \ lambda _ {\ rm {L}} ^ {3}} {4 \ eta _ {\ rm {L}} (\ vartheta _ {\ rm {s}} - \ vartheta _ {\ rm {0}})}} {\ frac {1} {x}} \ right] ^ {1/4}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/0cab11800421a568db67dfd5d56e8b76f591bb8e)

![{\ displaystyle \ alpha _ {\ rm {m}} = {\ frac {1} {H}} \ int _ {0} ^ {H} \ alpha \, {\ rm {d}} x = {\ frac {4} {3}} \ alpha (x = H) = {\ frac {4} {3}} \ left [{\ frac {\ varrho _ {\ rm {L}} (\ varrho _ {\ rm { L}} - \ varrho _ {\ rm {G}}) g \ Delta h _ {\ rm {v}} \ lambda _ {\ rm {L}} ^ {3}} {4 \ eta _ {\ rm { L}} (\ vartheta _ {\ rm {s}} - \ vartheta _ {\ rm {0}})}} {\ frac {1} {H}} \ right] ^ {1/4}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/f43856730573a8434d0b3b1d3126cf9977c52b4d)

![{\ displaystyle \ delta = \ left [{\ frac {4} {3 \ sin (\ varphi) ^ {4/3}}} \ int {\ sqrt [{3}] {\ sin (\ varphi)}} \, {\ rm {d}} \ varphi \ right] ^ {1/4} \ left [{\ frac {\ lambda _ {\ rm {L}} 3 \ eta _ {\ rm {L}} r} {\ varrho _ {\ rm {L}} (\ varrho _ {\ rm {L}} - \ varrho _ {\ rm {G}}) g \ Delta h _ {\ rm {v}}}} (\ vartheta _ {\ rm {s}} - \ vartheta _ {\ rm {0}}) \ right] ^ {1/4}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/621827941b2d95421257e202352f924a5586792c)

![{\ displaystyle \ left [\ alpha _ {\ rm {m}} \ right] _ {0} ^ {180} = 0 {,} 8057 \ left [{\ frac {2 \ varrho _ {\ rm {L} } (\ varrho _ {\ rm {L}} - \ varrho _ {\ rm {G}}) g \ Delta h _ {\ rm {v}} \ lambda _ {\ rm {L}} ^ {3}} {3 \ eta _ {\ rm {L}} (\ vartheta _ {\ rm {s}} - \ vartheta _ {\ rm {0}})}} {\ frac {1} {d}} \ right] ^ {1/4}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/a3e93a590d234bee80d487e77835914931282dbe)

![{\ displaystyle {\ frac {\ alpha _ {\ rm {m, horizontal}}} {\ alpha _ {\ rm {m}}}} = 0 {,} 772 \ left [{\ frac {H} {d }} \ right] ^ {1/4}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/8538808136b815bc97aa515ef5913e21590e8207)

![{\ displaystyle w _ {\ rm {G}} ^ {2}> {\ frac {4 \ varrho _ {\ rm {L}}} {\ zeta \ varrho _ {\ rm {G}}}} \ left [ {\ frac {12 \ lambda _ {\ rm {L}} \ eta _ {\ rm {L}} (\ vartheta _ {\ rm {s}} - \ vartheta _ {\ rm {0}})} { \ varrho _ {\ rm {L}} (\ varrho _ {\ rm {L}} - \ varrho _ {\ rm {G}}) g \ Delta h _ {\ rm {v}}}} \ right] ^ {1/4}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/ee0e38599ef92ad3ba23ceaad071bdc4ecd2f319)