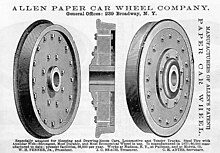

Paper wagon wheels

Paper wagon wheels ( English paper car wheels ) were composite wheels of railway carriages, in which multiple layers verpresstes laminated paper between the cast iron hub and made of wrought iron or steel wheel tires was screwed and protected on both sides by cast iron plates. They dampened the wheel-rail vibrations and ensured a smooth run, especially in North American sleeping and dining cars.

concept

The inventor of the paper wagon wheels was the train driver Richard N. Allen (1827–1890), who founded a factory with his brother-in-law in 1857 that made paper from straw. Paper wagon wheels dampened the vibrations much better than conventional cast-iron train wheels , which transmitted any bumps on the rail joints in the wagons above them, making the train journey often noisy and uncomfortable. They were primarily used in Pullman sleeper and dining cars, although occasional criticism that they led to derailments. From 1915, they were no longer approved for intermodal passenger transport.

Manufacturing

About two hundred round paper disks were sandwiched together using conventional starch- based paste . First, three panes were glued together, then stacked about three to four feet high and pressed with a 650-ton press for three hours and then dried. The process was then repeated with three sets of three-ply composite panels. The disks, each 13 mm thick, were glued together until a thickness of 90 mm was reached. The paper disk produced in this way was drilled out and turned off. The composite parts were then dried and cured in a warm room for six to eight weeks until all moisture had escaped. Then they were brought to the required size in a lathe and provided with at least 24 drill holes. The composite paper disk was protected on both sides by 6.35 millimeter (¼ inch ) thick gray cast iron plates. The hub was pressed into the composite paper disc with 25 t pressure and the wheel tire was pulled on with 230 t pressure before it was screwed to the front and rear mudguards and at least 24 bolts to form a complete wheel. Once the screws were tightened, the paper was so stiff and strong that it could support the weight of a railroad car.

United States

Allen Paper Car Wheel Works was initially located on East North Street in Morris, Illinois , while its main office was at 239 Broadway in New York . The factory mainly supplied the Pullman Palace Car Company in Chicago , which had placed its first order for 100 wheels in 1871 after testing and improving the wheels. As a result, the main plant was relocated to South Bay in Hudson (New York) in 1873 , and finally to the grounds of the Pullman works in Chicago.

In 1881, the Allen Paper Car Wheel Company had workshops in New York and Chicago, but kept their paper-making facility in Morris. Each workshop employed around 80 people who produced more than 24 bikes a day. So they produced and sold thousands of bikes a year. In 1886 the company announced that 60,000 bikes were already in use, and seven years later there were 115,000. The Allen Paper Car Wheel Works remained in operation until 1890 when it was sold to John N. Bunnell and changed its name to the American Straw Board Company. As a result, the company and its plants were leased, sold and restructured several times. They worked under different names for two decades, including the Morris Box Board Company. In October 1915 the company was restructured and incorporated into the Morris Paper Mills. In the 1920s, the paper mill was one of the largest employers in Morris, producing cardboard boxes of all shapes, sizes, and colors for sale nationwide.

Great Britain

The company John Brown & Co in Sheffield, England, has come to an agreement with the inventor regarding the manufacture of paper wheels in Europe and in October 1875 had already set up the machines required for this, so that production was expected to begin shortly at that time.

Germany

At the suggestion of head machinist Finckbein in St. Johann (Saar) and foreman Caesar of the Reichseisenbahnen in Alsace-Lorraine , the Adt brothers' oil board and varnish factory in Forbach (Lorraine) , a factory of the Adt paper mache dynasty , produced a paper stock after various tests, which was suitable for train wheels. With the approval of the Royal Railway Directorate in Frankfurt am Main , wheel sets with paper disks were manufactured and put into use in the Burbach main railway workshop and in the van der Zypen wagon factory in Deutz . Such wheel sets with disks made of paper stock were in regular service on wagons for a long time. They held perfectly and ran very smoothly while driving, without making any annoying noises.

The wheels used in Saarbrücken were constructed like the wooden Mansell wheels , with the wheel tire being placed on the paper disc and the hub in the same under strong hydraulic pressure, while the tires of the American paper wheels were provided with an inner shoulder against which the paper disc was pressed with which it was connected by bolts. Practice showed that the tires with such an internal approach, apparently because of the uneven distribution of mass, cracked from the inside out, so that the advantage that one wanted to achieve by reinforcing the tires was lost and an opposite result was achieved . In the ordinary Mansell wheels with wooden disks, the tires were also able to move further when heated by braking by causing a rotation on the wooden disk. The wheels designed in Saarbrücken therefore had four iron dowels on each side between the tire and the Mansell ring, which prevented the wheel tires from turning when braking.

Patents

- U.S. Patent No. 89,908 , May 11, 1869, RN Allen & LW Kimball: Original Patent

- U.S. Patent No. 128,939, July 16, 1872, Richard N. Allen: Improved construction of wheel

- U.S. Patent No. RE 7,142, May 30, 1876, Richard N. Allen: Reissue of U.S. Patent No. 89,908

- US Patent No. 182,789, October 3, 1876. Richard N. Allen & Albert B. Pullman: Cartwheels with different elastic materials between tire and hub instead of paper.

See also

Individual evidence

- ^ A b John H. Lienhard: Engines of Our Enginuity, No. 758: Paper railroad wheels.

- ↑ a b c d e Ken Cupery: Paper Railroad Wheels?

- ↑ a b c Paper Wheels. In: A Car-Builder's Dictionary.

- ^ Thomas Curtis Clarke: The American Railway: Its Construction, Development, Management, and Trains. Skyhorse Publishing, 2015.

- ^ Helena E. Wright: George Pullman and the Allen Paper Car Wheel. In: Technology and Culture. Vol. 33, No. Oct. 4, 1992, pp. 757-768.

- ^ J. Wallace: Pullman Palace Car Works: The Allen Paper Wheel Company.

- ↑ a b Müller-Melchiors: Notes from the world exhibition in Philadelphia 1876: 79. Railway carriage wheels with paper filling. In: Polytechnisches Journal . 224, 1877, pp. 121-128.

- ^ A b John E. Eichman, Sr: Paper Passenger Car Wheels. In: The Proto Journal , Volume 4, No 2.

- ^ A b c d Then & Now: Morris Paper Mills - Morris. In: The Herald-News , October 18, 2017.

- ↑ Allen's elastic railway wagon wheels. In: Stummer's Ingenieur: international organ for d. Total area d. techn. Knowledge u. Repertory d. most outstanding foreign. Fachjournale, No. 95, Volume 4, Fromme, 1875, p. 189-190.

- ↑ a b Railway wagon wheels made of paper. In: Polytechnisches Journal . 242, 1881, Miszelle 5, pp. 68-69.