Deep pump

Deep pumps are used as conveying devices for the extraction of liquids stored underground when the reservoir pressure is not sufficient for them to reach the surface independently or in sufficient quantities. They are mostly used to produce crude oil . Other areas of application are the promotion of brine and medicinal waters .

Types

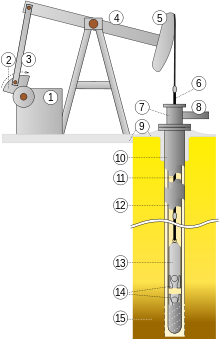

first drive motor with gear

2. counterweight

3. Connecting rod

4. Balancing

5. Horsehead

sixth piston rod

7. seal as part of the production cross

8 anchor casing string of the well

9 Zementage behind pipe string

10. Outer anchor pipe string

11. sucker rod

12 Inner well casing

13. Downhole pump

14.

Pump valves 15. Oil-bearing rock layer

A distinction is made between several types of deep pumps

Rod deep pump (horse head pump)

The image of most oil fields is dominated by rod pumps, which because of their appearance and movement are also called horsehead pumps, nickers or nickers. The actual pumping mechanism - a piston with check valves - is located in its own pipe string in the borehole near the oil-bearing layer. The piston is set in a continuous up and down movement by means of a screwable rod from a pump bracket located on the earth's surface. This is done by the so-called horse head. This consists of a segment of a circular arc arranged as a balancer , to which a pair of steel cables or chains is clamped at the top, which always exerts tension and never pressure on the rod.

The drive is mostly electric. However, if there are sufficient energy-containing gases dissolved in the petroleum, some of these gases can be separated from the conveyed material on site by means of a degasser and fed to a gas engine that drives the pump.

In the early days of oil production, central drives were common. In the most common type, an internal combustion engine drove a horizontal mechanism made up of eccentric disks into which rods were suspended. The linkage was thereby set in a back and forth movement, which was often transmitted over several hundred meters to the pump drives and converted there into an up and down movement. One motor often drove more than ten deep pumps. Such central drives are still used today in some oil fields in the USA.

Depending on the type and size of the pump, the working stroke is 1 to 5 m. Two and a half to twelve strokes per minute are common. The rod deep pump can be used economically up to a delivery depth of around 2500 m. For greater depths, other pump systems are better suited due to the great weight of the liquid column to be lifted.

Hydraulic drive

A hydraulic drive is particularly suitable for bores with a deflected course, in which a constantly moving rod would wear out quickly . The actual pump mechanism - like a piston with non-return valves in the rod-type deep pump - is actuated by means of a hydraulic cylinder located directly above the piston, which is connected via its own pipeline to a hydraulic pump located on the surface. The oil extracted serves as the operating medium for the entire pump system.

Eccentric screw pump

Instead of a piston pump , an eccentric screw pump (technical term PCP from English progressive cavity pump ) can be installed in the borehole, which is set in rotation on the surface of the earth via a screwable rod with a drive head. For deep bores or those with a deflected course, an electric motor attached directly to the eccentric screw pump is common. Power is supplied through a cable located in the borehole. The common in the oil industry term for electric submersible pumps (ESP English electrical submersible pump ).

history

The horse head pump is an invention from the 1920s. The inventor is Walter W. Trout (1900–1971), who initially worked in the sawmill business with his company, the Lufkin Foundry and Machine Company . Since the business field had to be given up at this time, he looked for a replacement for his wooden structures. After the President of the Humble Oil and Refining Company and later Governor of Texas, Ross S. Sterling , invited Trout to a discussion of production problems in oil fields with low reservoir pressure in 1923 , Trout accepted the order to develop a method using his wooden structures in order to be able to organize such funding economically. After a few unsuccessful attempts, he then applied for a patent for a working prototype in 1925.

Such pumps have been used in Germany for oil production since the 1940s. Today there are around 1400 of these systems in Germany.

A group of conventional deep rod pumps in the Hochleithen oil field, northeast of Vienna .

Small rod deep pump that is used to extract medicinal water at Bad Hall .

Driving head for an eccentric screw pump installed in the borehole .

The "Mark II" pump type from the Texan manufacturer Lufkin Industries is particularly suitable for high pumping rates from great depths thanks to its special movement geometry (slow upward and fast downward movement).

Deep pump drive on a platform in Lac de Biscarrosse et de Parentis in Aquitaine , France

literature

- Friedrich P. Springer: From Agricola's “pomps” in mining, “which pulls the water through the wind”, to the rod pumps in oil production , Erdöl / Erdgas / Kohlen Zeitschrift, issue 19, 2007.

Web links

- Horse head pump - technical things in the landscape , project raw material history, accessed on November 28, 2015

- Historical central drive with eccentric mechanism in operation , youtube video, accessed on November 28, 2015

Individual evidence

- ↑ Walter W. Trout. Retrieved May 28, 2017 .

- ↑ Torque and force curve of a horse head pump. Retrieved May 28, 2017 .

- ^ Martin S. Raymond, William L. Leffler: Oil and Gas Production in Nontechnical Language . PennWell Corporation 2006, p. 10

- ↑ Wintershall: 90 years of horse head pumps. Retrieved May 28, 2017 .