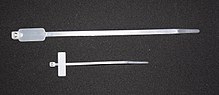

cable ties

A cable tie (or cable strap, plastic handcuff) is a universally applicable, quick-to-use and inexpensive connecting element .

Originally developed to fix different cables and entire cable harnesses to one another or to other objects, cable ties are now used in many other areas of application, in the construction industry for temporary assembly, as packaging aids or in police practice for tying people up.

Further developments of cable ties, e.g. B. with injection-molded fastening elements such as adhesive bases , stick anchors or lamellar feet have found their way into the automotive sector in particular.

history

Before the invention of the cable tie, wire harnesses were held together with wire or wax tape. This technique is known as tying or tying off. The inventor of the cable tie is George M. Rapata, in whose name the patent US 2936980 is from October 1, 1954 and who worked for Illinois Tool Works. New types of cable ties from Thomas & Betts came onto the market in 1958, and polyamide PA6.6 has also been used as a material since 1968 .

material

Until the introduction of the PA6.6, cable ties were mainly made of PVC. It was cheap to produce, but had the disadvantage of not being weatherproof and aging too quickly.

Today cable ties are mainly made of polyamide 6.6. This material is also commonly referred to as nylon known, but nylon is a trademark of the company DuPont . There are also cable ties made of other materials such as B. polyurethane to stainless steel .

The locking principle is usually a notch made of the same basic material as the cable tie, which acts on the ribbed side of the cable tie in the pulling direction. Metal notches are also used. These are suitably arranged so that self-locking occurs. The tape of the cable tie is then made smooth. Metal cable ties almost exclusively use the principle of self-locking.

Polyamide 6.6 is used because it has many properties that are very beneficial for cable ties and fasteners, such as:

- self-extinguishing

- high strength, rigidity and hardness

- high dimensional stability, even when exposed to heat

- high abrasion resistance, excellent resistance to alkalis, oils, oil products, lubricating greases, chlorate solvents

The material has a limited resistance to acids.

In contrast, cable ties made of polyurethane have the following properties:

- tear-resistant and highly elastic up to 400% elongation

- UV and weather resistant

- chemical resistance e.g. B. against oil, grease and solvents

- Operating temperature −40 to 85 ° C, also higher for a short time

- no embrittlement at low temperatures

- Hydrolysis and microbe resistance (especially specially treated material mixtures)

- very good resilience

- good dynamic resilience

- high kink and tear resistance (high tear and tear resistance)

- electrically insulating up to 10 GΩ

- hardly inflammable according to UL 94 HB

An important aspect for cable ties that are used in the European Union is the REACH regulation, so that processing is also permitted in public buildings.

Different types by material

A wide range of types of polyamides and additives allows the properties of the finished product to be optimally adapted to the respective requirements. The following variants can be used:

- Polyamide 6.6 standard (PA66) for temperature requirements up to +85 ° C

- Polyamide 6.6 heat-stable (PA66HS) for temperature requirements up to +105 ° C

- Polyamide 6.6 UV-weather resistant (PA66W) for use outdoors

- Polyamide 6.6 heat-stable and UV-weather-resistant (PA66HSW) for use outdoors up to +105 ° C

- Polyamide 6.6 impact resistant (PA66HIR) for high demands on elasticity

- Polyamide 6.6 impact resistant and heat stabilized (PA66HIRHS) for high demands on elasticity and temperatures up to +105 ° C

- Polyamide 6.6 V0 for high demands on fire protection

Also z. B. in network technology special cable ties are used for identification. These then have a widened part that is used for labeling.

Water content

Polyamide is a hygroscopic plastic. This means that the material absorbs water, but can also release it again. At a standard climate of 23 ° C and 50% relative humidity, saturation with water is reached at approx. 2.5% for polyamide. The mechanical properties - in particular the flexibility and the minimum holding force - are significantly influenced by the water content. For the optimal processing of the cable ties it is therefore important that the polyamide is in a state of equilibrium with a water content of approx. 2.5%.

The quality and processability of the products is therefore influenced by the water content. Correct storage of the products is therefore crucial.

For the private sector, brittle cable ties can almost regain their original flexibility by storing them in water for approx. 30–60 minutes.

Manufacturing

Cable ties are manufactured using the injection molding process. For this purpose, the raw material (granulate) is heated to a specified temperature and liquefied. The PA 6.6 is then pressed into an injection mold at high pressure. As a rule, around 50 cable ties are created in one operation.

Since PA6.6 is a hygroscopic plastic, it loses its water content during this process. For this reason, brand manufacturers always put some liquid in the packaging, which is then completely absorbed by the cable tie (packaging that has been opened longer should be closed again with a splash of water to ensure optimal durability).

species

Disposable cable ties

The toothing ensures that the cable tie can no longer be opened. It can normally only be reopened by destroying it. In the case of cable ties with a locking tongue made of plastic, however, it is usually possible to unlock it with a needle and thus open the loop again.

Double head cable ties

The tape can be pulled twice through the cable tie head through two openings in the head. In this way a loop is created. This means that two lines or line pairs can also be connected to one another.

Cable ties with an open tie head

The cable tie can be pre-locked through an open tie head. In this way, several cables can be laid one after the other in the cable tie loop without the tie being looped shut. Only after all cables have been laid is looped in.

Cable ties with stainless steel tongue

Introduced by Thomas and Betts, these cable ties have a higher pulling force than normal cable ties. A small metal tongue worked into the head closes the cable tie by cutting the tongue into the cable tie body.

Reusable cable ties

Reusable cable ties are cable ties that can be unlocked and re-used several times. However, they usually do not have the tensile load of a one-way tie.

Heat-resistant cable ties

By incorporating phosphorus, a cable tie becomes more resistant to heat and can withstand temperatures of up to 145 ° C. You can easily recognize these cable ties by their greenish color. Furthermore, so-called “designer polymers” such as polyetheretherketone (PEEK for short), polyamide 4.6 (PA46) and E / TFE (Tefzel®) are heat-resistant materials that are suitable for applications where temperatures of +150 ° C (PA 46), + 170 ° C (E / TFE (Tefzel®)), +240 ° C (PEEK) (continuous operating temperature) can be reached.

Stainless steel cable ties

In addition to PA6.6 and PVC, stainless steel is also used as a material. Stainless steel cable ties have a very high tensile force and are very resistant to UV and corrosion. Because of their high cost, they are often used in areas that are difficult to access after installation, so that replacement would no longer be possible or very difficult.

Highly elastic cable ties made of polyurethane

In contrast to normal rigid cable ties made of PA 6.6 or PVC, there are highly elastic soft cable ties made of polyurethane (PUR). This type is used for sensitive cables or in agriculture and forestry, e.g. B. for tying trees or vines, which is why they are also known as tree ties. The trees are not pinched by the elasticity, as is possible when using wire or string. The resealable Softbinder variant with double head is versatile, especially when it comes to quick laying and loosening, e.g. B. in laboratory structures or in exhibition stand construction. The disadvantage is the higher price compared to PA 6.6 and PVC due to the more complicated production.

Seals

Since normal cable ties can be opened again with a needle, there are also seals . These are designed in such a way that they cannot be opened even with tools. Often they also have a labeling field.

Other areas of application

Bondage

Cable ties are also used in security for restraint , as disposable handcuffs or ankle cuffs . They are mainly used when it is likely that a large number of people will have to be handcuffed, for example during riots in connection with demonstrations or sporting events. Police officers can carry a larger number of shackles with them, which would be difficult with the metal handcuffs otherwise used for reasons of weight. Cable ties also usually offer more adjustment options than metal handcuffs, which is why they are also used when a person needs to be handcuffed who do not fit ordinary handcuffs, for example because their wrists are particularly strong or particularly thin.

Cable ties with only one loop and cable ties with double loops are used as restraints. With the latter, each wrist is individually placed in a loop and then pulled tight. Since disposable cable ties represent a not inconsiderable expense, there are also reusable cable ties for restraint that can be opened again with a handcuff key.

Sometimes cable ties are also used in the area of erotic bondage games.

The use of cable ties, especially in the area of the wrists , can lead to nerve damage (see detainee paralysis ). In particular in the case of a permanent tensile load or if the device is applied too tightly, damage can occur which is often not noticed in the current situation and can lead to damage lasting for months, if not permanent. The nerves of the thumb are particularly often affected, the damage usually being accompanied by a feeling of numbness.

The elastic types made of polyurethane (soft binders) offer a better alternative.

labeling

Cable ties with a labeling field can also be used in the area of cable identification. They are also suitable for closing and labeling sacks.

standard

The DIN EN 62275 standard specifies the following article properties for the use of cable ties for use in electrical installations:

- Minimum installation temperature

- Minimum application temperature

- Minimum holding force (described in the standard as a loop tensile strength test)

- Stress and heat aging

- Temperature cycles

- Fire contribution

- Corrosion resistance

alternative

Cable harnesses and individual cable strands can also be tied together using strong cord and Marlschlag ties, where otherwise many individual cable ties would be required. The labor-intensive cord binding has been abandoned and is rarely found.

Velcro cable ties with Velcro can also be used. These can be easily removed again, but do not have such a high tensile force.

Another alternative to resealable cable ties is the “Cable Cuff” or the “Cable Wraptor”. The "Cable Wraptor" can also be hung up and has a handle

Marlschlag binding

Cable tie with Velcro on a power supply unit

Web links

Individual evidence

- ↑ Q-tie cable ties with the tie head open

- ↑ rapidart, Darmstadt / Germany: handcuffs, handcuffs - the history of handcuffs, handcuffs. (No longer available online.) In: handschellen.biz. Archived from the original on May 8, 2016 ; accessed on November 27, 2016 .

- ↑ VDP GmbH: Detailed view of weapons and equipment technology. In: polizeipraxis.de. May 8, 2014, accessed November 27, 2016 .

- ↑ VDE 0604-201, DIN EN 62275: 2010-07, Cable management systems - Cable ties for electrical installations

- ↑ Manufacturer's website Heinrich Kopp GmbH

- ↑ DIY-Info.de

- ↑ Manufacturer's website Cable Cuff