Roller lock

The roller lock is a locking system for automatic weapons. There are fully locked roller locks and those where the opening is only delayed.

The fully locked support roller lock

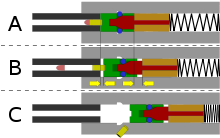

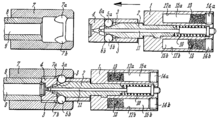

The support roller lock is used in various gas pressure and recoil chargers . It locks the locking head (red) firmly in the cam piece (complete locking) using the lateral rollers (purple). The control piece (green) prevents the rollers from sliding under load from the cam piece into the bolt head. Only when gases penetrate the gas cylinder through the gas extraction hole in the barrel and move the gas piston, the bolt carrier (dark blue) is moved backwards. The control piece is also pulled out of the bolt head. The pressure acting on the bolt head via the cartridge base can now push the rollers out of the cam into the bolt head, which is then unlocked. Now the bolt head also moves back and pulls out the empty case. After the case has been ejected and the parts of the slide are in their rearmost position, a spring pushes all parts forward again and at the same time a new cartridge is fed.

The best-known representative of a recoil loader with support roller lock is the MG 42 and its successors. With this weapon, the slide and barrel run back together until they are separated by inserting the rollers. The Czechoslovak pistol vz works on the same principle . 52 in caliber 7.62 × 25 mm Tokarew M1930 .

Movably supported roller lock

The movably supported roller shutter is a delayed mass closure that uses the inertial forces of masses to delay the opening of the closure after the shot has been fired. A mechanical translation of the return makes it possible to use smaller masses, which makes it suitable for handguns with powerful calibers. The structure and manufacture are relatively complicated and expensive. Its advantages are that relatively low masses move in a straight line along the barrel axis during the shot. This has a positive effect on the precision. In addition, the system is not stressed by force peaks.

After the cartridge has been ignited, the light bolt head should initially return slowly so that the cartridge is not pulled out of the chamber before the pressure in the barrel has dropped sufficiently. The bolt head and bolt carrier would be too light to delay the return movement directly through their inertia. The force acting on the bolt is therefore transferred to the bolt carrier by means of a transmission, which is thereby accelerated more strongly than the bolt head (see also the law of levers ). Due to its mass inertia, it opposes this acceleration with a force that is increased by the translation on the side of the bolt head. This inhibits the return of the bolt head.

After the shot has been fired, the cartridge case moves backwards due to the gas pressure in the cartridge chamber; it is based breech in the bolt head (green in the picture), and also moves it backward. In order for the bolt head to move backwards, however, the rollers (blue) must be pressed into the bolt. However, these only have sufficient space in the bolt head when the control piece (red) moves backwards. Due to the inclined angle in the curve piece and on the front part of the control piece, the control piece and the bolt carrier (brown) have to move many times backwards for every millimeter that the rollers push inward through the curve piece. This makes the control piece and bolt carrier faster than the bolt head. In this way, the closure can absorb higher kinetic energy. The slower bolt head only removes the case completely from the chamber when the gas pressure has dropped to a safe level.

Fluting in the front part of the chamber (pressure compensation grooves) compensates for the gas pressure inside the case and between its outer surface and the chamber in order to reduce the frictional resistance caused by pressing the case . This avoids tearing off the case base and case tears in other places and enables the case to be pulled out without problems, and a functional reserve is also provided. "The statement that the pressure compensation grooves do not solve functional and safety problems via the locking system, but rather via the sleeve material is certainly correct."

The movably supported roller lock was mainly developed by Theodor Löffler and Ludwig Vorgrimler . It is mainly used for weapons from Heckler & Koch ( Heckler & Koch roller lock weapons ). Examples are the P9S pistol , the MP5 submachine gun , and the G3 rifle .

In the case of pistols, the breechblock is usually firmly connected to the housing ( slide ). These two components then run backwards together. To push the bolt forward again, a spring is wound around the barrel, which is compressed by the front end of the slide when the shot is fired.

Advantages of the movably supported locking system

- The advantages of the bulk seal are retained.

- A low pull-out speed is guaranteed. This ensures good support for the lock.

- The movement of the closure parts and the housing follows the gas pressure without any time delay. The simultaneous play-free start of all movements of the closure parts and the housing prevents jerky and uncontrolled impacts.

- The force resulting from the recoil has an effect over time without force peaks. This is gentle on the material.

- Neither the barrel nor the bolt perform any rotating or tilting movements, which is beneficial for precision.

- The cartridge case pushes the slide and is not pulled out. As a result, the extractor is only stressed when the case is ejected from the weapon.

Disadvantages of the movably supported locking system

- Since the backward-acting impulse is divided in this system, with weak ammunition it can happen that the impulse for the breechblock is too small and there is no sufficient functional reserve available. The case is then not fully pulled out or ejected and no new cartridge is fed.

- The bolt carrier distance, i.e. the play between bolt head and bolt carrier, must be carefully observed. If the play is too small or too large, the rollers are no longer pressed correctly into the curve piece. Then the sleeve can possibly be pulled out while the barrel is still under pressure.

- In the case of sustained fire, the hammer is released during the advance of the slide and runs after it. If the initiation of the ignition coincides with the occuring breech rebound, the ignition is initiated at a time when the acceleration system is not in the functional position; the shutter runs too fast and opens too early. For this reason, a rebound protection (reference mass that has a pushing effect on the lock) is necessary.

- Operationally, the closure requires a strong impulse by pressing in the rollers, i.e. H. the lock must be closed with rapid (loud) sliding back, which can be heard by the opponent.

Well-known weapons with roller lock

See also

Individual evidence

- ↑ Wolfgang Pietzner: Waffenlehre, 1st edition: - Fundamentals of system theory , work on study and practice in the Federal Border Guard, Part 4, pp. 57–59, Lübeck, 1998, ISBN 3-930732-32-7 ( PDF ).

- ↑ Wolfgang Pietzner: Waffenlehre, 1st edition: - Fundamentals of the system theory . Work on studies and practice in the Federal Border Guard, Part 4, Lübeck 1998, ISBN 3-930732-32-7 , p. 56 ( PDF ).