Delayed mass closure

The delayed ground lock , also known as a braked ground lock, is an intermediate form between the locked and unlocked ground lock of an automatic weapon.

Working principle

Early attempts

With the friction lock, the return of the one-piece lock block was delayed by friction. The thread pitch of screw caps was chosen so that the closure block was only released after the gas pressure had dropped sufficiently. Another method was to let the breech block run up onto a ramp. As early examples of the guns of Schonberger and can Andreas Wilhelm Schwarzlose from the early nineties of the 19th century, the Villar-Perosa M1915 submachine gun and the American Thompson - Automatic Rifle are called with screw cap. On the Savage Model 1907 pistol, the barrel rotates. This is connected to the lock via a curved link that releases it after turning the barrel by 5 °. This rotation is slowed down because the bullet's rotational acceleration exerts a counterforce through the pulls.

Today's applications

The locking of weapons with delayed mass locking usually consists of two components, the bolt head and the control piece behind it. Both are connected by a mechanism that, on the one hand, engages in the lock housing and thus slows down the return movement of the lock head, and on the other hand, accelerates the control piece several times over due to the resulting force. This has the effect that the control piece, due to its inertia, inhibits the return of the bolt head until the lock is released. The bolt then runs back and the next cartridge is reloaded. The acceleration of the control piece and its mass are calculated in such a way that the bolt head can only move back freely when the gas pressure has largely decreased during the barrel.

Pressure compensation grooves

Since the return of the cartridge base and bolt head begins immediately with the build-up of pressure in the barrel, tensile stress is created in the cartridge case, which can be problematic when using bottle neck sleeves . Since the part of the sleeve that tapers towards the front is pressed forwards by the gas pressure and thus blocked, this can lead to sleeve tears. To avoid this, pressure equalization grooves are made in the tapered front part of the cartridge chamber, so that the internal pressure on the case cone is equalized. The continuation of the grooves in the chamber also ensures that gas penetrates the cylindrical gap between the case and the chamber, the case is then pulled out floating. In previous weapons, the cases were prevented from tearing with grease. The principle of pressure compensation grooves was first used in the Soviet Tokarev self-loading rifle and in the Winchester Model 1940 , an experimental rifle in .30-06 caliber for the US Marines.

Weapons with delayed mass locking

Skoda MG 1893/1902

As early as 1893, the Austro-Hungarian army gave the Skoda M93 machine gun to the troops on a trial basis. The weapon developed by the Austrian Archduke Karl Salvator and Ritter von Dormus had a two-part locking mechanism. Its two components, the lock and the delay mass, were pivoted on an axle. When the weapon was ready to fire, the delay mass supported the breech, when fired it was set in rotation and released the breech with a delay. The recoil spring was tensioned by the rotation of the delay mass, so that the reloading process was initiated. The rate of fire could be regulated by adjusting the pendulum weight between 180 and 250 rounds / min. Cartridges were fed from above. The cartridges had to be oiled to ensure proper function. Both weapons used the Mannlicher cartridges used by the Austro-Hungarian Army at the time.

Schwarzlose machine gun model 1907/1912

With the Schwarzlose MG , the return of the breech is delayed by an almost closed knee joint; this is hinged to the front of the housing and to the rear of the bolt head. A lever attached to the rear of the knee joint transfers the movement in an accelerated manner to the rear component of the lock, which is loaded by the closing spring, which also contributes to the delay. The barrel was kept short to prevent gas escaping to the rear. Case tears were avoided by oiling the cartridges.

Thompson self-loading rifle

The breech of the self-loading rifle, developed by the American company Auto-Ordnance from 1917 , was based on the principle of the interrupted artillery screw locks. The cylinder lock used in the Thompson rifle has an interrupted thread; this fits into the nut thread in the lock housing. The pitch of the six-start thread is calculated in such a way that the lock only unlocks when the gas pressure has largely fallen. To open, the lock must turn 90 °; in order to allow the return movement, the angle of the load-bearing thread sectors must be less than 90 °. The closure is made in two parts for additional delay; the contact surface of the two components lying one behind the other is designed as a double helix. When the front component rotates, the rear component is additionally accelerated, as its rotation is prevented by guides lying parallel to the axis.

The closing spring behind it is tensioned and the reloading process is initiated. The rifle is a shooting weapon . The cartridges had to be oiled to ensure their function and to avoid tearing. As with repeating rifles with cylinder lock, the bolt handle is used for loading. The inventors' assumption that the delay was due to the effect called blish lock , on the basis of which he patented his blish lock , was wrong . It is based on the inertia of the translated accelerated masses as well as the frictional resistance in the threads, the double helix and the parallel guides in the lock housing. In the evaluation of the US Army for the replacement of the Springfield M1903 repeating rifle, the Thompson was tested as early as the 1920s, but it did not prove itself and was rejected.

Thompson submachine gun

In the case of the Thompson submachine gun developed by the American company Auto-Ordnance , the two-part bolt slides back in a square bolt housing. The two locking components are connected by an H-shaped intermediate piece made of bronze. This delays the return of the bolt head with two locking elements by engaging in short 45 ° upward millings in the bolt housing. Since it slides upwards in the bolt head at an angle of 70 °, it also brakes it. At the same time, the H-piece accelerates the rear component of the lock, the control piece pressed forward by the closing spring, which also carries the loading button protruding from the top of the lock housing. As soon as the locking elements of the H-piece are released, the entire locking system can run back, the closing spring is tensioned and the reloading process is initiated. The first Thompsons M 21 (1921) had a rate of fire of 800 rounds / min. To set the rate of fire to 600 rounds / min. To reduce this, the mass of the rear component on the 1928 model was increased and the recoil spring was replaced by a harder one with a smaller diameter. Later, simplified variants of the Thompson have a one-piece ground lock and work perfectly. The Thompson submachine gun is a shooting weapon , it shoots the .45 ACP cartridge.

Pedersen self-loading rifle

As with the Schwarzlose MG, the opening of the breech is delayed by a knee joint. However, this is not kinked like the Schwarzlose, but almost completely stretched. The knee joint forms an approximately isosceles triangle in which the vertical intersection (or the pivot point) between the two legs is close to the baseline. The specially calculated shape of the contact or rolling surfaces ensures that the pivot point is less distant from the baseline when the locking head moves back than would be the case with a conventional knee joint. This means that the counterforce of the spring-loaded knee joint lasts longer, which maintains the retardation of the return movement of the locking head longer in the initial phase.

Although the Pedersen rifle fired relatively weak ammunition in the .276 Pedersen caliber, the cartridges had to be greased or waxed in order to ensure proper functioning. In the evaluation of the US Army for the replacement of the Springfield M1903 rifle in the 1930s, the Pedersen was in competition with the gas pressure loader developed by John C. Garand , the M1 Garand in the original caliber .30-06 Springfield , which was finally included in 1936 the US Army .

SIG MKMO submachine gun, Remington Model 51 pistol

In the SIG-machine gun MKMO, (actually M achines k arabiner, M ilitär, case ejection: o ben) and the Remington Model 51 gun is the closure in two pieces. With the MKMO it consists of a bolt head and control piece, with the Remington 51 it consists of a bolt head and slide. When firing, both of them run back together until the bolt head, which was tilted when fired, hits a locking shoulder in the bolt housing (or in the handle) after a few millimeters and is stopped. The accelerated tax piece, respectively. Due to their inertia, the carriages run back further, tilt the bolt head out of its locking position after a certain distance and run backwards together against the force exerted by the closing spring, whereby the reloading process is initiated. The disadvantage of this system, which was patented by the American weapon specialist John D. Pedersen, is that the slide retracts by a few millimeters without braking and is therefore unsuitable for bottle neck sleeves.

Reising submachine gun

The breech of the Reising submachine gun is a typical friction lock . The one-piece locking block must first overcome the resistance of a ramp and tip over before it rolls back. The braking torque is increased by the angled contact surface with the pull rod. The loading lever is located in a slot at the bottom of the fore-end at the front end of the retrieval rod. The loading movement releases the locking of the breech, which facilitates the loading process. The advantage of the friction system, patented by the American engineer Eugene Reising in 1940, is that the bolt mass can be kept lower than that of weapons with a pure mass bolt such as the American Cal .45 M3 “Grease Gun” submachine gun.

The weapon manufactured by Harrington & Richardson is a shooting gun, i. H. the slide is in the forward position before the shot. It fires .45 ACP cartridges either in single or series fire. A muzzle brake is attached to the barrel to reduce the recoil. The weapon was given to special forces by the US Army in World War II. A version developed for the American Marine Corps, the Model 55, had a folding stock , but no muzzle brake. A model 60 self-loading carabiner was also made later.

Glock pistols G25, G28 and G42

The Glock pistols G25, G28 and G42 in caliber .380 ACP have, in contrast to the guns locked in the Browning system in the stronger caliber such as the 9 mm Parabellum, a delayed mass lock . The barrel and breech are not locked when the shot is fired, the breech slide runs approx. 4 mm backwards until the front edge of the ejection opening hits the locking edge of the barrel, pulling it backwards and slowing it down somewhat. After 3 mm of mutual return, the barrel is lowered by the hook-shaped control link below the cartridge chamber, which further reduces the return speed of the breech. The slide covers the remaining distance to the stop on its own.

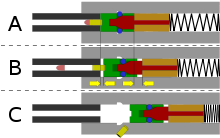

AA-52 machine gun, FAMAS rifle

The bolt of the French standard machine gun AA-52 and the FAMAS rifle consists of two parts, the bolt head and a heavier component behind it. Both are connected by a lever mechanism. With its shorter arm, the lever engages in a recess in the lock housing. Due to the force that occurs when the shot is fired, the bolt head moves slightly backwards, causing the lever to rotate. On the one hand, this leads to the fact that its longer arm accelerates the component attached behind it strongly backwards; on the other hand, the lock between the shorter lever arm and the lock housing is released. The slide runs freely backwards, the next cartridge is reloaded. In order to avoid case tears, pressure compensation grooves are milled into the tapered part of the chamber.

This design is based on a patent by John Pedersen from March 1922 for an unbuilt variant of the Remington 51 .

Guns with delayed roller lock

In the German assault rifle 45 and its successors, the CETME (rapid-fire rifle ) , the roller lock weapons from Heckler & Koch , the Swiss assault rifle 57 and the Calico weapons , the roller lock consists of the bolt head, the locking rollers and the control piece behind it. The closing spring located behind the control piece pushes it forwards, while the wedge located at the front of the control piece presses the locking rollers with its control surfaces into the abutments attached to the side in the lock housing. The weapon is locked and ready to fire.

The force acting on the bolt head when firing causes the bolt head to return. The locking rollers located between the bolt head and bolt housing transfer the recoil to the weapon housing via the abutments. At the same time, the pressure exerted on the locking rollers acts on the wedge of the control piece, this moves back, the locking rollers emerge from the abutments and the accelerated control piece pulls the bolt head backwards. The reloading process is triggered.

The shape of the abutment and the angle of the wedge on the control piece are calculated in such a way that the control piece is accelerated in relation to the bolt head. In addition, the mass of the control piece is greater than that of the bolt head. Both lead to a delay in the return of the bolt head. Since the bolt head is not blocked when the shot is fired, but moves backwards slightly, it must be avoided that the case is torn when the gas pressure is still high. For this purpose, pressure compensation grooves are milled into the tapered front part of the chamber in weapons with a delayed mass lock. The internal pressure on the sleeve cone and the cylindrical part of the sleeve is thus balanced.

Weapons with gas pressure delayed mass breeches

Like a ground lock, this system has no mechanical locking or delay. The return of the bolt is delayed by the gas pressure generated when the shot is fired. One or more gas extraction holes at the back of the barrel direct the gas into a cylinder that is attached parallel to the barrel. The piston located in it and connected to the closure is pushed forward by the gas pressure and thus delays the return of the closure.

The system on which the VG-45 is based was developed in 1944 under the direction of the then chief designer Barnitzke and was a novelty. The VG-45, however, does not have a separate cylinder. The gas extraction holes in the barrel direct the gas into a sleeve that is pushed onto the front end of the barrel and is connected to the barrel casing and the breech. The forward gas pressure in the sleeve delays the return of the system as long as there is gas pressure. The system has the advantage that the return of the closure is more or less delayed depending on the strength of the cartridge depending on the gas pressure. A disadvantage is the relatively large gas loss compared to weapons with mechanical locking and the contamination of the cylinder.

After 1945 the following self-loading pistols with a gas-delayed mass lock were developed: HK P7 , Steyr GB and Walther CCP . In Switzerland, the system was tested by the Eidgenössische Waffenfabrik, Bern (today RUAG ) on the 9 mm W + F 47 pistol (gas delay principle with reaction piston, Pat. 251151, October 15, 1947).

Weapons with a rotating head delayed ground lock

In 2017, the US company CMMG presented the pistol caliber rifle MkG45 Guard in caliber .45 ACP, which was based on the AR-15, followed by versions in 9 mm Luger (MkG-9) and other calibers. Unlike the Colt 9 mm SMG submachine gun and the civilian pistol carbine derived from it with a simple ground lock, the weapon developed by CMMG has a radial delayed blowback with the help of a rotating bolt head. The bolt head has seven locking lugs and is connected to the bolt carrier in its control cam by a control bolt. The locking lugs are beveled at their rear end and engage in corresponding recesses in the locking sleeve. The force that occurs when the shot is fired moves the bolt head backwards, which is simultaneously set in rotation by its beveled bolt lugs. By turning the bolt head, the return of the bolt is delayed until the gas pressure in the chamber has dropped to a safe level as a result of the projectile leaving the muzzle. Due to the rotating head-braked mass lock, both the bolt carrier and the buffer piece require a significantly lower mass than corresponding parts in conventional AR-15 pistol carbines of the same caliber, which significantly reduces recoil.

literature

- Jaroslav Lugs: Handguns. Systematic overview of handguns and their history. 2 volumes. 8th edition. Military publishing house of the GDR, Berlin 1986, ISBN 3-327-00032-8 .

- WHB Smith, Joseph E. Smith: Small Arms of the World. The basic manual of military small arms. American - British - Russian - German - Italian - Japanese, and all other important Nations. 5th edition, revised and enlarged, 3rd printing. Military Service Publishing Co., Harrisburg PA 1957.

- WHBSmith, Joseph E. Smith: The Book of Rifles , Copyright 1948 by the National Rifle Association, The Stackpole Co. Harrisburg, PA, USA

- Melvin M. Johnson, Charles T. Haven: Automatic Weapons of the World , Copyright 1945 by the authors. William Morrow & Co. NY, USA.

- George M. Chin, Lieutenant Colonel USMC: The Machine Gun , 1951 prepared for the Bureau of Ordnance, Dept. of the Navy, Washington DC, USA

- Tracie L. Hill: Thompson, the American Legend , Copyright 1996 by Tracie L. Hill, Published by Collector Grade Publications Inc. Cobourg, Ontario, Canada, ISBN 0-88935-208-9

- Eugen Heer: The handguns from 1850 to the present , Copyright 1976 Akademische Druck- und Verlagsanstalt, Graz, ISBN 3-201-00967-9

Individual evidence

- ↑ Lever delayed blowback. (No longer available online.) Archived from the original on July 24, 2011 ; Retrieved on August 15, 2014 (animated representation of a lever-operated delayed mass lock).

- ↑ U.S. Patent No. 1,410,270 to Google Patents

- ^ US patent [1] at Google Patents