Safety trough

A safety trough , also known as a wash bowl, is a flat, plate-shaped vessel with a diameter of about 30 to 50 centimeters, which is used for the mechanical separation of heavy minerals , and especially solid gold , from suspended sands. For tourist and hobby gold panning , the name gold pan or gold panning pan has also become established (as a loan translation from English: goldpan ) .

history

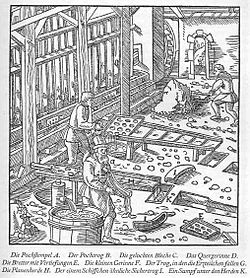

The forerunner of today's safety trough is the wooden Saxe or Saxon , which probably developed in Bohemia in the 14th century and was already known and used in Germany in the 15th century. Georgius Agricola describes them in detail in his main work De re metallica libri XII :

“This safety trough is smooth and 2 fingers deep, its shape resembles a small ship, because it is wider at the top, narrower at the bottom, and in the middle there is a transverse channel in which the pure gold and Deposit silver particles. The sand is washed away because it is lighter. "

“The safety trough is low and smooth because it is rubbed with oil or some other kind of grease so that the little gold dust does not stick to it; it is also colored black with soot so that the gold can be seen better. In addition, the safety trough is slightly notched at the bottom in the middle on both sides so that it can be safely grasped, held and moved with the hands. In this way the gold grains or bits collect at the rear of the safety trough and gradually migrate to the front when the rear is poked by hand, as is usually done. This is the way to wash gold , especially in Moravia . "

In order to be able to process larger amounts of sand, safety troughs up to 150 centimeters long were sometimes hung in racks on ropes and swiveled.

functionality

Today the safety troughs usually have a stepped or corrugated bottom, which facilitates the separation of the various minerals, and are made either of steel, wood or plastic. Plastic pans have established themselves in the hobby as well as in the professional sector.

When washing, the excavated material or sediment from flowing water is passed through a sieve into the safety trough and provided with water. The pan is set in gentle rotating movements. By exploiting the centrifugal forces and the different specific gravity of the various minerals, the lighter components move outwards, while the heavier components, such as heavy metals , larger lumps of gravel, dark sands, gold and platinum , remain in the middle, together with what is known as fool’s gold . The components that settle early are poured off. Larger chunks, such as gravel, are removed by hand. Subsequently, the sands are further separated by careful oscillating movements, the alluvial sands are separated by hand during the so-called "removal". This process is repeated several times.

During the process, the very high density of the gold (19300 kg / m 3 ) is used, which allows the gold to remain in the gold pan. The remaining, lighter components are rinsed out.

use

Nowadays, safety troughs are not only used by amateur gold prospectors. In the professional and semi-professional gold panning, the gold panning trough has meanwhile established itself , but especially in the so-called developing countries , safety troughs are still often used for the manual exploitation of soap deposits , for example for diamonds , noble beryls ( emerald , aquamarine ), noble corundum ( rubies , sapphires ) etc. to win.

The systematic washing of stream and river sediments is still one of the basic sampling techniques in the early phase ( reconnaissance ) of the raw material deposits - prospecting . The sediment concentrate obtained is sent to a geochemical laboratory and its components are analyzed.

Panning for gold with the pan in true Germany one day yield of 200 milligrams - what about an hourly wage of 50 cents corresponds - as a good result, which is why it has been in Germany only tourist importance.

literature

- Georg Agricola : De Re Metallica Libri XII . Twelve books on mining and metallurgy. Unchanged reprint of the first edition by VDI-Verlag, 1928 edition. Marixverlag, Wiesbaden 2006, ISBN 3-86539-097-8 (Latin). ( Digitized German translation by Schiffner 1928 )

Web links

Individual evidence

- ^ Georg Agricola: De Re Metallica Libri XII. Twelve Books of Mining and Metallurgy, p. 279.

- ^ Georg Agricola: De Re Metallica Libri XII. Twelve Books of Mining and Metallurgy, p. 282.

- ^ Georg Agricola: De Re Metallica Libri XII. Twelve Books on Mining and Metallurgy, p. 280.

- ^ Georg Agricola: De Re Metallica Libri XII. Twelve books on mining and metallurgy, pp. 281/282.