Silicoater process

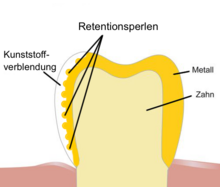

The silicoater process is an adhesive process from dental technology , with the help of which an adhesion mediation between metal on the one hand and plastic or ceramic on the other hand is produced. This allows a tooth-colored cladding (technical term: veneer ) made of plastic or porcelain to be permanently attached to a metal restoration, such as a tooth crown or bridge element made of precious or non-precious metal, or to a model cast prosthesis .

The silicoater process is a special form of flame coating , in which the surface is not only treated with a flame made of ethyne (acetylene) and oxygen or propane and oxygen, but silane oxides are added to the surface . These are deposited on the surface, creating a primer by "silicating" and anchoring the adhesion promoter by silanizing . A silane primer is applied to which a coating material is then applied.

The process was developed in 1984 at the Friedrich Schiller University Jena , the Technical University of Dresden and the Central Office for Corrosion Protection in Dresden. By silanizing the metal surface, a reliable bond between the two materials could be achieved. Until then, plastic veneers were attached using retentive elements such as retention pins or retention beads.

Individual evidence

- ↑ Manfred Rasche: Manual Bonding Technology . Carl Hanser Verlag, October 4, 2012, ISBN 978-3-446-43198-0 , pp. 195-196.

- ^ R. Musil, H. Tiller: The molecular coupling of the plastic veneer to the alloy surface , dental laboratory, 32nd year (1984) issue 10, pp. 1155–1161

- ↑ H. Tiller et al .: Silicoater method improves adhesive strength and aging resistance, Adhäsion , 33 (1989) No. 10, pp. 27-31