Watch industry

The watch industry is the serial production of watches in industrial companies . In terms of production technology, a distinction is made between fabrication, i.e. H. the production of watch components (e.g. raw works, shells, pointers) from raw materials ( blanks ) and the assembly of these individual components to make the finished watch.

history

The industrial production of clocks does not begin with pocket watches , but with large clocks . The motherland of the watch industry is the United States. In 1804 the watchmaker Ely Terry (1772-1852) received an order for the delivery of 4,000 movements. To do this, he developed clockworks with interchangeable parts. With the help of machines and devices, the individual parts were manufactured so precisely that they could be assembled without reworking. This system of interchangeable components is one of the key principles of industrial production.

When brass, which had been expensive until then, became available cheaply thanks to industrial production from around 1835, metal clockworks with exchangeable parts were also created. The wheels and blanks were machined by punching and bending. The works could be produced accordingly inexpensively. These "American movements" became a model for industrial watchmaking even in Europe and Asia. But first they pushed the traditional craft production as well as the hitherto very successful domestic watch production in the Black Forest into a deep crisis. In many small workshops in the Black Forest, large numbers of wooden clocks had been produced since the second half of the 18th century. Thanks to the division of labor and simplified construction, they were unrivaled in terms of price until the first industrially manufactured timepieces appeared.

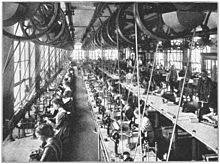

The production of pocket watches in Switzerland, which is dominant in Europe, with centers in Geneva and the Jura, faced comparable problems. Here, too, the production of portable watches was organized based on division of labor and, in some cases, already mechanized. In 1777, Frédéric Japy (1749–1812) in Beaucourt , on the French side of the Jura, began to produce blanks for pocket watch movements using new types of machines. The individual work steps were simplified so that “women, old people, even blind people” could manufacture the individual parts for the clockwork with a simple hand lever. The production numbers literally exploded. In 1780 Japy produced 30,000 pieces, in 1806 more than 150,000 pieces. At that time he already employed 500 workers. Even this first step towards the industrialization of watch production led to a drop in the price of pocket watches.

The Swiss watch region, spoiled for success, fell into a deep crisis around 1870. In 1872 366,000 watches could still be delivered to the United States, in 1875 it was only 70,000. The reason for this: The United States had successfully begun to manufacture clocks in factories with the help of special machines and using a maximum division of labor. From the 1876 World's Fair in Philadelphia, on which a sample production by the Waltham Watch Company was built, the Swiss delegation reported relentlessly: "In America you work better and cheaper." The workload per pocket watch in the United States was 20 hours compared to 75 hours in Switzerland, where 75% of the employees were still working from home. A rethink began in Switzerland. More and more watch factories switched to the American system of production, with success: as early as 1900 the Swiss watch industry had ousted the United States again from first place.

The domestic watchmaking industry in the Black Forest had gone through a comparable crisis until, towards the end of the 19th century, based on the American model, industrial production methods also prevailed.

For large parts of the 20th century, watch production in the Black Forest dominated exports all over the world for large clocks (alarm clocks, wall and grandfather clocks), while pocket and wristwatches came mainly from Switzerland. The watch factories in the United States produced primarily for the domestic market. Significant competition arose from the emerging Japanese watch industry. But there were also watch factories in almost all European countries and overseas.

With the transition from traditional mechanical watches to electronic timepieces (keyword: quartz crisis ) in the last third of the 20th century, the European and American watch industries disappeared completely, apart from a few remains. Only niche providers like Swatch were able to hold their own against the overwhelming Asian competition. Around 1990 a renaissance of the mechanical wristwatch began, which is especially popular with men as a high-priced accessory. In terms of numbers, however, luxury watches from Switzerland and elsewhere do not play a role in overall watch production.

present

Today, as in other branches of industry, the manufacturing part of watchmaking is highly automated, and human activities in the factory halls are limited to logistics and work preparation as well as control and maintenance work. In terms of the market, watch production and sales are globalized today. The latest players are some emerging Asian countries, first and foremost, of course, the rapidly emerging China. Not only original or cheap watches come from Asia, but also, to a considerable extent, cheaper counterfeits from well-known European brands, which is increasingly causing headaches and legal costs for European manufacturers.

The Swiss watch industry is once again an economic factor in the typical watch production regions. In 2015, a total of 28.1 million watches were exported for CHF 21.5 billion, the world market is estimated at 1.2 billion pieces. It is the largest watch exporter in the world in terms of value and the third largest in terms of quantities, and employs around 60,000 people.

Documentation

- Watch paradise Switzerland: Kathrin Winzenried on a journey through time in the Jura. Video in: DOK , Swiss television from October 20, 2011, Swiss German .

Web links

literature

- Estelle Fallet, Béatrice Veyrassat: Watchmaking. In: Historical Lexicon of Switzerland .

- Johannes Graf: From one hundred to zero in 40 years. The German clock industry in the post-war period. In: German Society for Chronometry. Jahresschrift, Vol. 50, 2011, pp. 241–262.

- Helmut Kahlert: 300 years of the Black Forest watch industry. 2nd completely revised and updated edition. Katz, Gernsbach 2007, ISBN 978-3-938047-15-6 .

- Jakob Messerli: Precision in masses. Clocks and clock production in the USA and Europe in the 19th century. In: Living Time. Published by Henning Schmidgen, Berlin 2005.

- Musée International d'Horlogerie (ed.): Philadelphia 1876: Le défi américain en horlogerie. Catalog d'exposition May 6th-30th September 2011 / De l'unique à la série: L'interchangeabilité. Actes de colloque 19. – 20. October 2010. La-Chaux-de-Fonds 2011.