Suction air brake

The suction air brake , also called air suction brake , is a service brake for locomotives and wagons used in railway operations to brake trains . In contrast to the compressed air brake , which is predominantly used today , the suction air brake does not work through overpressure, but rather through a negative pressure compared to the prevailing ambient air pressure . The brake got its name after the air suction device used to generate the negative pressure . The name vacuum brake , which is common in Switzerland , was also used in Germany in the past .

Working principle

With the suction air brake, the braking force arises from the fact that different levels of pressure act on the two sides of the brake cylinder piston.

In order to use the suction air brake as a continuous train brake, all vehicles of the train are connected with a suction air line (Switzerland: main vacuum line ). The suction air hoses of the couplings used to be recognizable by their helical reinforcements. In the meantime, hoses without a visible helix are also used. There are no stop cocks on the vehicles. Compared to compressed air brakes, the hose couplings are less complex, as the sealing surfaces automatically press against one another due to the pressure difference to the outside air. Hose couplings that are not required are covered with blind plugs suspended from the head piece (for example in Saxony) or permanently attached (Great Britain and the Iberian Peninsula). A distinction is not made between automatic and automatic brakes according to the mode of action . Both types correspond in their structure to the direct-acting or the indirectly-acting compressed air brake .

Non-automatic suction air brake

With the suction air brake that does not work automatically, a vacuum must be created in the brake cylinder and in the suction air line for braking. To release the brake, you open a valve that connects the line to atmospheric air pressure . When the pressure is fully equalized, the brake pads are released from the wheel tires .

The non-automatic suction air brake was partly responsible for the Armagh railway accident in 1889 , which cost 80 lives. The non-automatic suction air brake is not approved as a service brake on railways.

Self-acting suction air brake

The automatically acting suction air or vacuum brake, also called automatic vacuum brake (aV), works in a similar way to a two-chamber air brake such as B. the Knorr two-chamber brake Kzbr or the two-chamber brake cylinder of the Kunze-Knorr brake . The mechanical part of the suction air brake system with brake linkage , brake pads, etc. largely corresponds to the constructions used for air brakes. Since the lower pressure differences in suction air brakes require larger brake cylinder diameters, they are usually installed vertically. In vehicles that are used across borders in networks with suction and air brakes, as was the case in the past in traffic with the Iberian Peninsula and Great Britain, suction and air brake cylinders act independently of one another on the same brake linkage.

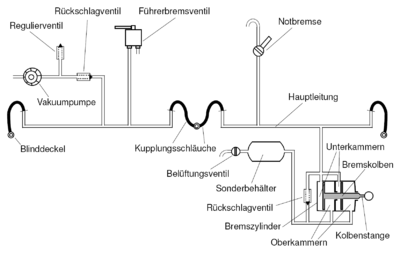

Evacuate or release

The vacuum pump on the locomotive sucks (evacuates) the air from the entire system via a check valve , which creates a negative pressure. In steam locomotives this is generated with an ejector that is combined with the driver's brake valve . The lower chambers of the brake cylinders are evacuated via the main air line and the upper chambers and the special containers are evacuated via non-return valves. When the brake cylinder is mounted horizontally, a return spring or, when the brake cylinder is mounted vertically, the weight of the piston holds it in the release position. The brake is ready for operation or released when a pressure difference of 52 cm Hg (690 hPa ) is generated between the atmospheric pressure and the system and there is pressure equalization between the lower and upper chambers of the connected brake cylinders. On the locomotive, a regulating valve limits the pressure difference between the atmospheric air pressure and the main air line to 52 cm Hg. A check valve prevents the uncontrolled penetration of outside air when the vacuum pump is at a standstill.

Brakes

With the driver's brake valve, the vacuum in the main air line and the sub-chambers of the brake cylinders is reduced by the controlled intake of outside air. The negative pressure of 52 cm Hg in the upper chambers and the special containers is maintained thanks to the automatic sealing by the built-in check valves. As a result of the pressure difference in the two chambers, the force of the return spring or the weight of the piston is overcome and the piston moves into the braking position.

In the event of rapid or emergency braking , the suction air line is connected directly to the outside air. This destroys the negative pressure in a very short time and achieves the maximum braking effect. If the train is separated, the negative pressure at the separation point is also reduced immediately.

Advantages and disadvantages compared to the air brake

- The suction air brake can be easily regulated and, in particular, released gradually. It is inexhaustible. Both of these made them particularly suitable for mountain railways. With the relatively short trains, the higher air consumption compared to single-chamber brakes did not play a decisive role. These advantages were no longer significant when the multi-release air brake was introduced.

- Because of its simple structure, the suction air brake is insensitive and easy to maintain. No malfunctions can occur due to condensation water freezing in the air duct .

- While the compressed air brake enables brake cylinder pressures of several bar - up to 3.8 bar are common - the pressure difference in the suction air brake is limited from the outset by the atmospheric air pressure (approx. 1 bar); actually only about 0.7 bar is achieved. In order to achieve a comparable braking force (pressure difference × piston area), the brake cylinders must have approximately two and a half times the diameter.

- The suction air brake reacts more slowly.

- The breakdown speed of the vacuum brake is generally 15, with rapid braking approx. 200 m / s. It is therefore lower than with the compressed air brake.

- Mechanical anti-slip protection cannot be implemented with the suction air brake.

- In steam operation , the high steam consumption of the ejector is a disadvantage. On the other hand, the ejector is much simpler and less prone to failure than the air pump required for the compressed air brake, as it has no moving parts.

Vacuum controlled air brake

The vacuum-controlled air brake has the advantage over the pure vacuum brake that it can be equipped with an anti-skid regulator. The combination with a maneuvering brake and a skid brake is possible for traction vehicles . However, the vehicle requires compressed air, which is supplied either from an air compressor or from the feed line .

The vacuum-controlled compressed air brake is equipped with a vacuum control valve in addition to the pure vacuum brake . This has the same function as the air brake control valve.

See also section Vacuum control valve in the article Control valve (railroad)

Types of construction and distribution

The Hardy suction air brake and Körting suction air brake (Köbr) are distinguished by the names of the manufacturers of the respective brake equipment . Both types can be used together.

Both designs can still be seen in use on some of the Saxon narrow-gauge museum vehicles and on the Bruchhausen-Vilsen museum railway .

See also: Narrow gauge railways in Saxony

In Austria , from 1891 until the beginning of the Second World War, suction air brakes of the Hardy and Körting designs were used on the predecessor railways of today's Austrian Federal Railways . Passenger cars for international traffic were equipped with a compressed air brake in addition to the suction air brake. The vacuum brake is still widely used on narrow-gauge railways, e.g. B. at the Mariazellerbahn or the Waldviertel narrow-gauge railways .

In Switzerland around 1900, vacuum and compressed air brakes were about equally common on narrow-gauge railways. On the occasion of modernization of the rolling stock, most railways have since switched to compressed air brakes. Aside from the museum railways , you can find suction-braked trains on the Rhaetian Railway , the Matterhorn-Gotthard Railway , the Montreux – Berner Oberland Railway and the Transports publics Fribourgeois .

In Great Britain (including Ireland ), in the British colonies as well as in Spain and Portugal, the automatic vacuum brake was standard . It was gradually replaced by the air brake, in the United Kingdom from the 1970s. The Indian Railways and in South Africa the vacuum brake is still used.

literature

- Federal Office of Transport: Page no longer available , search in web archives: driving regulations . Bern 2012. R 300.14 Appendix 1, Section 7

- Heinz Russenberger: Suction air or vacuum brake . In: Four-axle passenger coaches of the SBB from 1912 - 1929 (= Loki-Spezial ). No. 31 . Lokpress, Zurich 2009, ISBN 978-3-9523386-2-9 , p. 10-11 .

Web links

Individual evidence

- ↑ a b Vacuum brake in English-language Wikipedia, accessed on January 18, 2014.