Rotary valve

Rotary feeders are devices for dosing, feeding or discharging fine-grained and dusty products or granulates .

use

- Rotary feeders are installed under silos and bunkers in order to relieve the bulk material of the silo pressure and to relieve downstream extraction devices such as screws , trough chain conveyors , pipe chain conveyors or extracting weighfeeders , etc.

- Rotary sluices are installed under filters and cyclones in order to be able to remove bulk goods from air conveying circuits with the lowest possible pressure loss.

- They are installed in mixers, dryers and mills for volumetrically metered feeding or feeding of the bulk material into continuous mixing and processing processes. In combination with weighing devices, rotary feeders can also be used for more precise gravimetric dosing.

- In the case of flammable bulk material, the rotary valve can be used as a burn-back protection, for example to safely prevent burn-back from a biomass boiler to the pellet store.

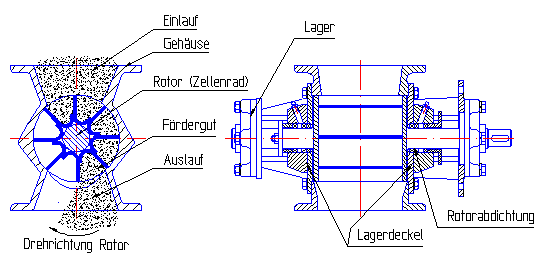

Function and structure

The function of the rotary valve is based on a rotor on which there is a certain number of rotor blades, which rotates in a precisely fitting housing. Each rotor cell picks up the conveyed goods under the inlet opening and the conveyed goods fall out at the outlet. This creates a volumetrically continuous delivery. The delivery rate is determined by the content of the rotor cells and the speed of the rotor. The direction of flow and counter flow of the conveyor system with certain pressure differences are effectively separated from each other by the tight tolerance between the housing and rotor

Rotary locks are manufactured in a wide variety of sizes (20 to 2000 mm), materials ( steel , stainless steel , aluminum , gray cast iron ) and designs (discharge lock, clearing wheel lock, tangential lock, blow-through lock, knife lock).

Types

Discharge lock

The discharge lock is the most common type of rotary valve. It is used for the volumetric inward or outward transfer of all kinds of bulk goods.

Medium pressure rotary valve

Areas of application: CFM rotary valves are mainly used for the metered discharge of granulates and powders from silos and as a feed unit in pneumatic flight conveyor systems with a pressure difference of up to 1.5 bar (g).

High pressure rotary valve

Areas of application: CFH rotary feeders are mainly used for the metered discharge of granulates and powders from silos and as a feed unit in pneumatic dense phase and air conveyor systems with a pressure difference of up to 3.5 bar (g).

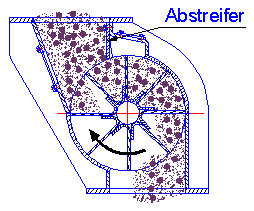

Clearing wheel sluice

Clearance wheel sluices are used for caked or slightly sticky bulk materials. A clearing wheel scrapes out the cells of the rotor and ensures that the respective bulk material is conveyed smoothly.

Tangential lock

Tangential locks are used for coarse-grained bulk materials and granulates. Due to the offset inlet, which is almost tangential to the rotor diameter, the bulk material is pushed back again by the scraper. This prevents the bulk material from jamming between the cellular wheel and the housing. The tangential sluice is often used when conveying and metering granulates to protect the product and prevent grain destruction .

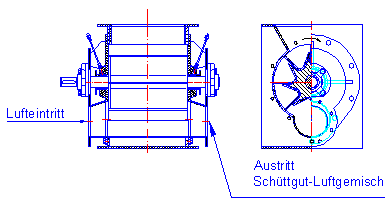

Blow-through lock

Blow-through locks are used to convey bulk goods in a pneumatic conveyor system. The cells convey the product into a conveying pipe. Here it is carried along by an air stream and blown into the delivery line.

Injector sluice

Injector locks are used like blow-through locks for conveying bulk materials into a pneumatic conveyor system. The rotary valve conveys the product dosed into the injector valve. Here it is carried along by an air stream and blown into the delivery line.

Chemical and pharmaceutical lock

Chemical and pharmaceutical locks are used for the discharge and dosing of powdered food, chemicals and pharmaceuticals.

The technical execution of the locks are usually subject to the

- GMP Good Manufacturing Practice (in German: Good Manufacturing Practice )

- FDA (Food and Drug Administration) requirements.

Quick cleaning of rotary valves

These rotary valves are used for the discharge and dosing of powdery food, chemicals and pharmaceuticals. The rotary valve can be cleaned well with the help of various pull-out devices.

Reduce cleaning times

The trend towards smaller batches continues in almost all sectors of the process industry. In compounding, for example, users are placing ever higher demands on the variety of products. The result is that colors or compositions change much more frequently and, accordingly, the systems have to be converted or components used have to be cleaned more often. For this, however, you need easily accessible components that can be easily cleaned, so that the times between batch changes can be drastically reduced.

Knife lock

Knife locks are used for the discharge of secondary fuels such as B. plastic and wood are used. The knife strips and fixed knives have the task of cutting protruding material and thus preventing the rotary valve from blocking.

Filter lock

Filter locks are used to remove filter dust from filters, separators and cyclones. Explosion-related decoupling for flame arrester in explosion protection can also be achieved using a suitable rotary valve certified as a protection system.