Serving measure

A serving measure is a serving vessel with a well-defined capacity . It is mostly used in the form of a drinking glass , beer glass , mug, mug or carafe and is required by law for the payment of drinks for immediate consumption within the European Union . This includes, depending on state law, even the payment of tap water. No volume information is required for vessels for serving coffee, tea or mixed milk beverages (e.g. cups, jugs, glasses). The volume information may also be missing for side glasses that are served together with a bottle or can that was originally closed and delivered in a defined manner. Even with free delivery or in the private sector, serving measurements are generally not required.

history

In the past, in addition to calibration laws and measuring device regulations, special dispensing vessel regulations had existed in German-speaking countries for over a century. The country-specific laws have meanwhile been harmonized within Europe by the Directive 2004/22 / EG on measuring devices (MID). The maximum ten-year transition period expired on October 30, 2016 for all EU countries and Switzerland. Thus, by this date at the latest, all serving measures produced, imported, traded and newly purchased must conform to the relevant EU directives.

Line, margin and transfer dimensions

There are different types of serving measures. A line measure has one to three filling lines, the upper edge of which indicates the lowest point of the meniscus of the liquid level at the respective nominal volume. In contrast, an edge measure is filled up to the edge of the vessel. The total internal volume is therefore the nominal capacity. A filling measure is a serving measure , from which the liquid is poured out before consumption.

Nominal dimensions

Possible nominal volumes are specified in the respective national laws. In Germany, 0.01; 0.02; 0.04; 0.05; 0.1; 0.15; 0.2; 0.25; 0.3; 0.33; 0.4; 0.5 l and 1; 1.5; 2; 3; 4; 5 l approved. In Austria, fractional nominal contents such as 1/32 are also permitted; 1/16; 1/8 and 1/4 l, also 0.025 and 0.75 l, but not 0.33 l. In addition, there are stipulations to what extent the volumes can also be specified in ml, cl, dl, cm 3 or dm 3 instead of liters . The abbreviation of the unit liter with a capital L is sometimes allowed.

In Great Britain, only Anglo-American measures of capacity are allowed for beer and cider : 1/3; 1/2; 1 pint and 2; 4; 8 and 16 pints. For wine and spirits, the information must only be given in milliliters and liters.

Filling line and tolerances

In the case of line and transfer dimensions, a filling line shows the respective standard volume. This mark is at least 10 mm long. Up to three such marks for different volumes can be placed on a vessel. This is a label for the information of the consumer, which is attached by the container manufacturer. However, this is not, as is often claimed colloquially, a calibration mark. A calibration should only be carried out by a calibration office or a state-approved test center. The validity of the calibration would have to be confirmed by an attached calibration mark. However, this is not the case with the calibration mark. The term fill line already exists in a German law from 1881.

In the case of opaque material, filling lines may also be applied inside the dispensing vessel in exceptional cases. However, the fill line must remain visible. If, for example, it is covered by beer foam, the consumer can request that the volume be confirmed by transferring it to a transparent container. In Switzerland, filling marks may also be affixed to the outside of non-transparent dispensing vessels, especially those made of ceramic. Outside Germany and Switzerland, however, only marginal dimensions are allowed for ceramic vessels.

The legislator allows the following tolerances when adding the filling line: less than 200 ml ± 5%, from 200 ml deviations between - (5 ml + 2.5%) and (5 ml + 2.5%) are permissible. For marginal dimensions without a fill line, it is correspondingly 0 to 10% or 0 to (10 ml + 5%) of the nominal volume. Lower error tolerances apply for transfer measures.

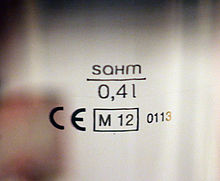

Labelling

The conformity is confirmed by the CE mark . The CE mark, which is at least 5 mm high, is followed by an equally high rectangle containing the metrology mark "M XX", where XX are the last two digits of the year the marking was affixed. At the end of a four-digit number that uniquely follows notified body identified (Notfied Body), which carried out the conformity procedures. The three elements may also be arranged one below the other instead of next to one another. In addition, the manufacturer of the glass must be recognizable through manufacturer information. This can be an abbreviation or an approved logo. In Germany, the manufacturer's mark is approved and published by the Physikalisch-Technische Bundesanstalt . For example, “Bö” stands for Böckling GmbH Neudenau, “Kö” for Kössinger AG Schierling, “ra” or “rastal” for Rastal , “Sahm” for Sahm or “VW” for Gerd van Well GmbH Krefeld.

Web links

- Consumer protection for dispensing vessels - Landesbetrieb Mess- und Eichwesen NRW (PDF file; 48 kB) ( Memento from February 12, 2006 in the Internet Archive )

Individual evidence

- ↑ a b c d e f WELMEC Measuring Instrument Directive (2004/22 / EC): Common Application - Capacity Serving Measures (CSM)

- ↑ a b Directive on the Ordinance of the FDJP on spatial dimensions of September 5, 2016

- ^ WKO: Metrological regulations for the use of dispensing vessels

- ↑ a b RIS federal standard Austria

- ↑ a b c d Growth database with all NB numbers

- ↑ PTB: Number of the notified body