BMW 801

| BMW 801 | |

|---|---|

BMW 801D |

|

| Type: | Radial engine |

| Design country: | |

| Manufacturer: | |

| Production time: |

1940-1945 |

| Number of pieces: |

more than 28,000 |

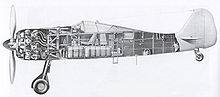

The BMW 801 is an air-cooled 14- cylinder - double star aircraft engine with direct fuel injection , which under the direction of Martin Duckstein in 1938 BMW was developed. Series production began in 1940 in the BMW aircraft engine factory in Eisenach . BMW developed 22 variants, eleven of which were built in series. In total, over 21,000 engines of this type were manufactured.

operation area

This engine became particularly famous because it powered one of the Luftwaffe's standard fighters in World War II , the Focke-Wulf 190 Series A, B, F and G series. The engines used in the Fw 190 were optimized by the loader stages for use at lower to medium altitudes, which later turned out to be a great disadvantage against Allied bombers and their escort fighters , as they operated at high altitudes of 8,000 to 10,000 meters.

technical features

Forced cooling

The BMW 801 was the first air-cooled multiple radial engine with fan cooling , in which the cooling air was forced through the engine casing by an axially mounted fan wheel mounted on the face. In contrast to pure airflow cooling, this design enabled reliable, controllable cooling even on the ground and at low speeds, and reduced the air resistance by reducing the entry area required for cooling. The oil cooler built into the front of the engine casing in a ring shape was also forced through by the blower air, which exited through an annular gap.

Single lever operation

The BMW 801 was one of the first aircraft engines with single-lever operation: A command device designed by Heinrich Leibach, as a mechanical analog computer , automatically set all parameters (such as ignition timing, throttle valve opening, charger gear, injection quantity, propeller adjustment) to match those of the pilot with the "power selector lever" specified boost pressure (or associated speed). Since no separate levers had to be operated for mixture and propeller adjustment, the pilot was relieved of engine operation and the risk of operating errors was reduced. The injection pump, also controlled by the command device, was a development by the Munich company Friedrich Deckel .

Short-term increase in performance

Various systems for short-term performance enhancement that could be used with the 801D-2 and its ancillary developments were developed. From 1943 onwards, a number of Fw 190 F / G fighter-bombers were fitted with a system for additional fuel injection ( C3 injection ). This increased the output for a short time from around 1730 hp to up to 1870 hp and could only be used in the first loader gear up to a maximum altitude of 1000 meters. From mid-1944, the Fw-190-A-8 fighters received a related system that also worked with additional fuel ( increased emergency power ). The system worked in both loading aisles and delivered up to 2100 hp in the second loading aisle. Due to the lack of fuel at the end of 1944 / beginning of 1945, the increased emergency power was converted to MW-50 (methanol-water injection), the maximum power then reduced to 2000 to 2050 hp.

Power plant

At the request of the Reich Aviation Ministry , the BMW 801 was not only manufactured as a built-in engine, but from 1942 also as a motor system, which also included the aerodynamic cladding that is usually part of the airframe, and from 1944 also as an engine system, which was also supplemented by an exhaust system and installation scaffolding .

Technical specifications

BMW 801 D-2

- Bore: 156 mm

- Stroke: 156 mm

- Displacement: 41.8 liters

- Compression ratio: 7.2: 1

- Boost pressure: 1.42 bar abs.

- Loader design: single-stage, two-speed

- Diameter: 1,290 mm

- Length: 2,006 mm

- Dry matter: 1,010 kg

- Start Power: 1,700 hp (1250 kw) starting performance at sea level at 2,700 min -1

- Propeller reduction: 0.54

- Full pressure altitude: 5,700 m

Versions

- 801A: bomber engine , manual electric propeller adjustment, engine system MA, engine system TZ

- 801B: 801A with counterclockwise rotating propeller (via reverse gear), not built

- 801C: Jäger engine, like 801A, but with automatic hydraulic propeller adjustment

- 801L: 801A with automatic hydraulic propeller adjustment from the 801C, engine system ML, engine system TZ

- second series, from 1942, single-stage two-speed charger, 1,700 hp take-off power, C3 fuel with 100 octane

- 801D-2: Jäger engine, improved supercharger, higher compression, 1941–45

- 801G-2: bomber engine, otherwise like 801D-2, engine system MG, engine system TC

- 801H-2: 801G-2 with counterclockwise rotating propeller, not built

- 801Q-2: 801D-2 with reinforced oil cooler armor, TU engine, 1944–45

- Further developments

- 801J: Further development of the 801D-2 with exhaust gas turbocharger, TJ engine, 1,810 hp takeoff power, 1944–45

- 801K: like 801J, with spur gear reversing gear (counter-clockwise propeller)

- 801S: 801D-2 with a better charger and other engine parts from the 801E project, reinforced oil cooler armor, 2000 hp takeoff power with MW-50 (2,200 hp possible from early 1945), TS engine, 1944–45

- 801H: similar to 801S

- Projects

- 801D: Fighter engine with single-stage three-speed supercharger for 87-octane fuel, development discontinued

- 801Ds: Jäger engine with turbocharger

- 801E: bomber engine, further development of the 801D-2 with a higher supercharger ratio, takeoff power 2000 hp

- 801F (-1): Jäger engine, further development of the 801E, takeoff power 2000 HP, with MW-50 system 2400 HP, in February 1945 with MW-50 system 2580 HP, engine system TH

- 801F (-2) 2400 HP take-off power, beyond that emergency power with MW-50 system; this engine differed significantly from the 801F-1, the designation 801F-2 would therefore be logical, just not found in the documents from BMW

- 801M: like 801Ds with a new turbocharger

- 801N: like 801E with a different loader

- 801R: Further development of the 801E with a two-stage four-speed charger

- 801 Heimstoffmotor: test engine to save alloy materials

All performance data as start-up and emergency power at sea level, around 70 to 100 HP for driving the fan wheel, are taken into account. The often stated 1600 HP of the first series was only reached at an altitude of about one kilometer, the 1730 HP of the second series from an altitude of 600 m. Unless otherwise stated, the crankshaft and propeller turned clockwise.

See also

Individual evidence

- ↑ United States Strategic Bombing Survey , Aircraft Division (Ed.): Aircraft Division Industry Report. Second Edition, January 1947, Table VII-1, pp. 99 ff.

- ↑ Time horizon brochure from the BMW Museum in Munich

- ↑ www.ju388.de Injection pump Friedrich Deckel from the BMW 801 radial engine

swell

- BMW 801 A / C / D manual, May 1942 edition

- Focke-Wulf Fw 190A manual, various versions

- BMW 801 A – C – D – G, MA, ML, aircraft engine and command unit: Technical Compendium, Aviation Archive, ISBN 3-939847-07-0

- Kyrill von Gersdorff, Kurt Grasmann, Helmut Schubert: Aero engines and jet engines. Bernard & Graefe Verlag, 1995, ISBN 3-7637-6107-1 .

- Airplane Classic 9/2007, article "The prevented successor" *

Web links

- BMW 801. In: BMW history. BMW AG, accessed on January 30, 2016 (dossier of the BMW Group Archives).

- Manual for the aircraft engines BMW 801 MA, ML, C, D series 1 and 2. In: BMW history. BMW AG, March 1941, accessed on January 30, 2016 (manual with pictures, 191 pages).

- BMW 801 & FW 190

- Scheme of command device

- Drawing command device