Biological methanation

The biological methanation (also microbial methanation) is a conversion process for the production of methane with the help of highly specialized microorganisms ( archaea ) in a technical plant. This process can be used in a power-to-gas plant for the production of biomethane and is evaluated as an important storage technology for fluctuating renewable energies in the context of the energy transition . The process was put into practice in 2015 in the world's first power-to-gas plant of this type.

Disambiguation

Biological methanation includes the principle of so-called methanogenesis , a specific, anaerobic metabolic pathway in which hydrogen and carbon dioxide are converted into methane . Analogous to the biological process, there is a chemical-catalytic process, also known as the Sabatier process .

functionality

Highly specialized microorganisms, so-called archaea , biocatalytically convert the compounds hydrogen (H 2 ) and carbon dioxide (CO 2 ) to methane (CH 4 ). The relevant microbial metabolic processes take place under strictly anaerobic conditions and in an aqueous environment.

Archaea suitable for the process are so-called methanogens with a hydrogenotrophic metabolism. They can basically be assigned to the genera Methanopyrales , Methanobacteriales , Methanococcales and Methanomicrobiales . In nature, these methane generators are adapted to different anaerobic habitats and environmental conditions. Basically, methanogens require aqueous, anoxic environmental conditions with at least 50% water and a redox potential of less than −330 mV. The methanogens prefer slightly acidic to alkaline living conditions and are found in a very wide temperature range between 4 and 110 ° C.

Possible applications of biological methanation

The biological methanation can take place as an in-situ process within a fermenter (see Figure 3.1) or as an ex-situ process in a separate reactor (see Figures 3.2 to 3.4).

Biological methanation in a biogas or sewage treatment plant with a gas processing plant (in-situ process)

For biological methanation, the hydrogen is added directly to the fermentation material of a fermentation process and then takes place in the fermentation material that has been gassed through. Depending on its purity, the gas is purified to methane before it is fed into the gas network.

Biological methanation in a biogas or sewage treatment plant without a gas treatment plant (ex-situ process)

The biological methanation takes place in a separate methanation plant. The gas is completely converted into methane before it is fed into the gas network.

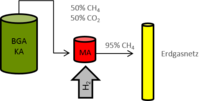

Biological methanation in a biogas or sewage treatment plant with a gas treatment plant (ex-situ process)

The carbon dioxide generated in the gas processing plant is converted into methane in a separate methanation plant with the addition of hydrogen and can then be fed into the natural gas network.

Biological methanation plant in connection with any carbon dioxide source (ex-situ process)

In a separate methanation plant, hydrogen is converted into methane together with carbon dioxide and then fed into the natural gas network (stand-alone solution).

Realization in practice

Since March 2015, the world's first power-to-gas plant in Allendorf (Eder) has been feeding synthetic biomethane, which is generated with the help of biological methanation, into the public natural gas network. The plant has a feed-in capacity of 15 Nm³ / h methane, which corresponds to around 400,000 kWh per year. With this amount of gas generated, a distance of 750,000 km could be covered annually in a CNG vehicle in a climate-neutral way.

Individual evidence

- ↑ Sterner, M. and Stadler, I .: Energy Storage - Demand, Technologies, Integration. Springer Verlag, Berlin, 2014

- ↑ http://www.microbenergy.com

- ↑ Fuchs, G. and Schlegel, HG: Allgemeine Mikrobiologie. Georg Thieme Verlag, Stuttgart, 2007

- ↑ Madigan, M., Martinko, J., Bender, K., Buckley, d. and Stahl, D .: Brock - Biology of Microorganisms. Pearson Education, Munich, 2009

- ↑ Bischofberger, W., Dichtl, N., Rosenwinkel, K.-H. and Seyfried, CF: Anaerobic Technology. Springer-Verlag, Heidelberg, 2005

- ↑ Ferry, JG: The chemical biology of methanogenesis. Planetary and Space Science (2010) No. 58, pp. 1775-1783.

- ↑ Bo Young, J., Kim, SY, Park, YK and Park, DH: Enrichment of Hydrogenotrophic Methanogens in Coupling with Methane Production Using Electrochemical Bioreactor. J. Microbiol. Biotechnol 19 (12) (2009), pp. 1665-1671.

- ↑ Boone, DR, Johnson, RL and Liu, Y .: Diffusion of the Interspecies Electron Carriers H2 and Format in Methanogenic Ecosystems and Its Implications in the Measurement of Km for H2 or Format Uptake. Applied and environmental microbiology 55 (1989) No. 7, pp. 1735-1741.

- ↑ What exactly is meant by volume flow in Nm³ / h? , last accessed August 29, 2019.

- ↑ About the "BioPower2Gas" project , last accessed on August 29, 2019.

- ↑ Helpers for the energy transition. In: sueddeutsche.de. January 18, 2016, accessed September 19, 2018 .

- ↑ Viessmann has put the power-to-gas system into operation ; Bio-Based News, March 23, 2015 , last accessed August 29, 2019.