Drilling platform

A drilling platform (also known as an oil rig ) as an offshore structure is an artificial surface in the sea that is used to drill holes, mostly in search of oil or natural gas .

Types

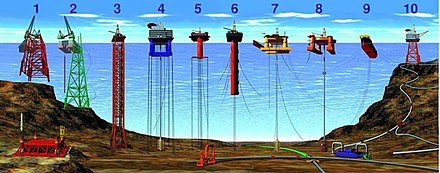

A total of five types can be distinguished:

- The fixed platform (engl .: Fixed Platform or Submersible rig ) communicates with a fixed base made of steel or concrete on the seabed . The tower platform ( Compliant Tower ) stands on one or more steel frame legs. The fixed platforms are pulled to the target area by tugs and lowered where they will remain until they are scrapped .

- The deck of a jack-up rig (engl .: jack-up rig ) stands on legs and frame is vertically movable. It is moved by tugs or transported over long distances by special cargo ships. They can be used up to a water depth of 130 m.

- The semi-submersible drilling rig (ger .: Semi-submersible rig ) has deep below the ocean's large buoyancy on which the platform rests legs relatively slender pillars. This reduces the influence of the swell with sufficient stability, to which the ballast in the floats contributes. Some of these rigs are held above the borehole by wide anchors . Others maintain their position with their own GPS- based and computer-controlled drive consisting of several thrusters that can be swiveled through 360 °. This type of drilling rig is used in great water depths of up to 3500 m. Because the semi-submersible rig is floating, it is one of the most mobile types of rig.

- The so-called TLP (for tension leg platform ) has a central buoyancy body that ends with a horizontal plate at a calm depth. The construction is held in an upright position by parallel, strongly tensioned steel cables between the edge of the plate and individual weights on the seabed, even if the structure is horizontally offset by wind or currents. A TLP is also often used as a production platform.

- In a variant of the TLP, the float is extended in the manner of a spar barrel and is only held upright by a single tension leg. Horizontal offset would cause the platform to tilt and is reduced by sloping moorings that are positioned higher up.

- The drilling ship represents another form. These ships are used in very great water depths (over 3000 m are common) and kept in position by the ship's propulsion system. Similar to the semi-submersible drilling rig , the drive often consists of swiveling thrusters or propeller pods , which are positioned depending on the type of ship.

After completing one or more boreholes, the drilling platform is towed or driven to the next location. If necessary, a production platform is then placed over the boreholes, which then takes over the production, processing and further transport of the crude oil or natural gas.

The largest production platform ever built is the Norwegian Sea Troll of the oil company Statoil with a million tons of water displacement. It measures 472 m in height from the base to the top of the gas torch mast and has stood on the sea floor at a depth of 303 m since 1995. If she were standing next to the Eiffel Tower , the Sea Troll would tower over it by 148 meters.

Possible uses

Drilling platforms do not only drill vertically into the depths. The existing possibilities of sinking one or more boreholes from a drilling platform had existed since 1975 with the cantilever and there were also kickoff boreholes back then, i.e. This means that the oil or gas carrier (mostly the Rotliegend ) could be drilled at an angle. However, should formation fractures occur in the deposit that has been drilled to date (so-called anticlines , discordances ), it is also possible to reach these with drilling technology from the same location. Today, as a result of advances in drilling technology and improved drilling fluids, a completely different application option is used in offshore production, namely the horizontal drilling of the deposit in its location over several hundred meters. This directional drilling makes it possible to develop a deposit from the side along its entire length and thus noticeably increase the flow of oil or gas. For example, from a few (expensive) drilling and production platforms, an encountered and recoverable deposit can often be completely sunk using drilling technology and thus fully developed for subsequent oil or natural gas production. But here, too, there are limits to the distance, on the one hand because of the hook load of the drilling machine or the regular load of the derrick, through the drill rods used and their expansion capability and through the mud pumps used with the drilling mud medium used and also used .

A special form of drilling rigs are on the edge of the Antarctic Research rigs used in small numbers, which as well as "untereisisch" drilling down bring under the sea, mostly to geological to do research, for example geological climate research and paleontological geology or seismograph for seismic safety and -exploring.

Oil rigs often serve as weather stations and with their measured values support the data that is usually only sparse over the oceans for weather calculations.

disposal

After the oil fields have been exhausted, for example , there is at least the theoretical possibility of sinking this drilling and production platform (see e.g. Brent Spar ) and in this way creating an artificial coral reef . Due to the heavy pollution of such an industrial plant, this disposal method can hardly be implemented without further damaging the environment, which is usually already polluted. For this reason, the 15 states participating in the OSPAR conference in 1998 decided to ban oil platforms in the North Atlantic from being dumped .

environment

Apart from local environmental pollution, drilling platforms represent a potentially great danger for the entire environment as an industrial plant, as so-called " blowouts " in particular can quickly pollute very large areas of water with leaking oil. For example, the oil spill in the Gulf of Mexico in 2010 was triggered by the explosion of the Deepwater Horizon drilling platform , which spilled around 700,000 cubic meters of oil into the sea.

Drilling platforms can also create new habitats for marine animals for the duration of their existence . On drilling rigs in the North Sea, fast-growing tropical mussel species have been settling on the permanently warm production pipes for a long time and cause problems there when there is heavy vegetation. They die when production is stopped and leave a crust that is repopulated when production is resumed.

See also

- Borehole surveying

- Oil production

- List of accidents on drilling and production platforms

- National Master Plan for Maritime Technologies

Web links

- WWF: Oil rig endangers gray whales

- Offshore: Superlative conveyor systems

- Small series of pictures of the largest oil rigs

Individual evidence

- ↑ Troll-A Platform: Largest Object Ever Moved by Man amusingplanet.com March 12, 2013.

- ↑ The ban on sinking oil platforms DIE WELT of July 25, 1998.

- ↑ oil spill in the Gulf of MexikoRSS spiegel.de topic.