Briquetting press

The briquetting , collecting or briquetting press (colloquially also "briquetting machine") is a device with which material is briquetted , that is, it is compacted and pressed into a handy format, the briquette . In addition to the original use for the production of coal briquettes from lignite or coal dust, other materials are now also pressed, including wood for use as a biogenic fuel ( wood briquette ).

history

The lignite industry experienced its first major boom between 1880 and 1910 . This is in large part due to the invention of the briquetting or briquetting press by the German Carl Exter . With their help, the combustibility of the coal could be increased significantly. In addition, the overall energy requirement increased sharply during this period. The demand for briquetted coal and thus for briquetting presses rose rapidly, both for household fuels and for power generation. A large number of briquette factories were built during this time.

Later on, the continuously produced waste from the wood industry, for example dust and shavings in carpentry shops or sawmills, was pressed into wood briquettes that could be heated, primarily as a proper and economical disposal of wood waste. The briquetting or briquetting press in a slightly modified form found its way into woodworking companies. Today, not only lignite or wood is briquetted, but also materials such as paper , biomass , cotton , hay , straw , miscanthus and dust as a regenerative energy source ( bioenergy ). In waste management, too, briquettes are used, reducing the volume and facilitating the transport and handling of substances (e.g. toxic dust).

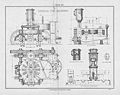

Steam-powered briquetting press of the briquette factory Louise (1882)

7-inch single-strand crank press (built in 1901), formerly in use in the Wachtberg briquette factory , today exhibited on the site of the former Sibylla briquette factory in Frechen

functionality

There are essentially three methods used for briquetting:

Extrusion

Piston extrusion

In the case of rod or extrusion presses , compression is usually carried out in piston extrusion presses. The material is fed into a cylindrical or angular channel and compressed by a piston that is driven mechanically by a flywheel or hydraulics . With the return stroke of the piston, new material is fed into the press channel and, during the forward stroke, the piston pushes it against the material already pressed in the previous stroke. The pressing pressure is created by the wall friction of the pressed strand in the pressing channel as counter pressure to the piston pressure and can be regulated by tapering the pressing channel. The pressed material emerges from the press channel in the rhythm of the piston blows. The pressing pressure, which in the case of wood briquettes is up to 1,200 bar, for example, results in very high temperatures in the pellet strand, which must be reduced by cooling, especially in larger systems.

Depending on the dimensions of the briquettes, bulk or stackable goods are produced. The shape of the press channel or the extruder head is responsible for the cross-sectional shape; pellets can also be produced by using a die head with several parallel press channel bores .

If the material fed in in portions caked in the press channel to form a coherent endless strand, it emerges continuously from the press channel and still has to be fed to a cutting and breaking device. Depending on the material used, however, it can also be that the material fed in in portions forms a separate briquette that can be easily separated from the previous or the following briquette, for example in the case of the known lignite briquettes. In this case, an engraving in the head of the press die can be used to emboss a text, a pattern or an image into the briquette.

Extruder presses

In addition to the piston extrusion presses, briquette strands can also be produced by extruder presses . The compression takes place here by a screw conveyor , which compresses the material into a strand and pushes it out through the extruder head. Due to the high energy consumption, however, the presses are only used comparatively rarely. The pressed material always emerges from the press channel as an endless strand.

Roller press process

With roller presses (usually with a perforated die), the roller pressure has a compacting effect. The process is mainly used for the production of egg coals (in southern Germany and Austria more like egg briquettes), approximately egg-shaped briquettes (mostly) made from hard coal. On closer inspection, the shape is elongated, lenticular, so that the pieces do not roll away and pack closer to the combustion chamber, as well as a blunt circumferential edge on the press seam so that the "egg" experiences high pressure and slides easily out of the hollow form in the roller.

Bale chamber process

In the press chamber process, the briquette is produced after pre-compression via a worm gear in a press chamber. This is a solid form. There the hydraulic ram compresses the material into compact, solid briquettes. The baling pressure is monitored automatically via a preset valve. After the set pressure has been reached, the press device opens automatically. The briquette produced is pushed out. The usually rectangular briquettes have the same shape and are therefore very easy to stack. The throughput of this process is usually lower than that of extrusion, but the energy requirement is significantly lower and the material does not need to be cooled.

Other procedures

In addition to the common form of the piston extrusion press, the bricolare press is also used in waste management , which produces compacts that quickly rot by hydraulic milling of a mixture of waste and sewage sludge. A similar principle is used in the production of wood pellets ( pelleting ), but these differ not only in their cylindrical shape from wood briquettes or other shapes, but also in the manufacturing process, which is technologically not briquetting .

Individual evidence

- ↑ a b Bernd Bilitewski, Georg Härdtle, Klaus Marek: Abfallwirtschaft , Springer, 1994. ISBN 3540642765 . Pages 387 ff.

literature

- Heinz M. Hiersig : Lexikon Maschinenbau , Springer, 1995. ISBN 3540621334