Biobutanol

| Biobutanol | |||||||

|---|---|---|---|---|---|---|---|

|

|||||||

| other names |

|

||||||

| Brief description | Fuel for Otto engines | ||||||

| origin |

biosynthetic or biogenic |

||||||

| CAS number |

|

||||||

| properties | |||||||

| Physical state | liquid | ||||||

| viscosity |

2.63 mm 2 / s at 40 ° C ( n -butanol) |

||||||

| density |

|

||||||

| calorific value |

|

||||||

| Octane number |

|

||||||

| Cetane number |

|

||||||

| Boiling range |

Boiling point 117.7 ° C ( n -butanol) |

||||||

| Flash point |

|

||||||

| Ignition temperature | 385 ° C ( n -butanol) | ||||||

| Explosive limit | 1.4-11.2% by volume ( n -butanol) | ||||||

| Minimum air requirement |

11.21 mol / mol ( n -butanol) 11.1 mol / mol (isobutanol) |

||||||

| safety instructions | |||||||

|

|||||||

| As far as possible and customary, SI units are used. Unless otherwise noted, the data given apply to standard conditions . | |||||||

As biobutanol (C 4 H 10 O) butanols are referred to, which are made from biomass , such. B. sugar , starch , straw or wood can be obtained. If cellulose-rich raw materials such as straw or wood are used, one also speaks of cellulose-butanol .

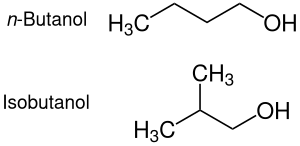

Of particular importance are n- butanol and isobutanol ( i- butanol) as biofuels . You can as admixtures for gasoline fuel for the operation of gasoline engines are used. n -Butanol can also be added to diesel and even used as a pure substance.

Various processes for the biotechnological production of n -butanol and isobutanol are known, but the production is not yet economical enough for a breakthrough.

Manufacturing

n -butanol

Bio-based n -butanol can be produced by fermenting vegetable, mostly previously processed biomass. The starting materials are carbohydrates , such as B. sucrose or starch . The best known is the acetone-butanol-ethanol fermentation , in which the bacterium Clostridium acetobutylicum is used. However, a number of other microorganisms (e.g. genetically modified yeast, Escherichia coli , ...) that can produce n- butanol more easily and cost-effectively are currently under development .

The difference to ethanol production is primarily in the fermentation, while the distillation is very similar. Existing bioethanol plants can be converted relatively easily to the production of n -butanol.

Isobutanol

Isobutanol is also a by-product, e.g. B. in the metabolism of yeast , and is formed there in small quantities when the amino acid valine is broken down. The incorporation of this metabolic pathway into various other microorganisms in order to achieve higher efficiency has been successfully tested. On a laboratory scale, isobutanol could also be produced in genetically modified bacteria using CO 2 , which was electrochemically converted into formate .

Potential as a fuel

Since biobutanol is made from renewable raw materials, the advantages and disadvantages are similar to those of all other biofuels . n -Butanol is conceivable as an additive for both gasoline engines and diesel engines . For the mixture with diesel it is assumed that in this way soot and nitrogen oxide emissions can be reduced. However, the cetane number is below that of diesel and biodiesel , which makes auto-ignition more difficult.

In 2005 it was shown that n -butanol can also function as the sole fuel by running an old Buick on pure n -butanol. Compared to petrol operation, however, a car powered by n -butanol would have higher consumption and less power.

Isobutanol can also be used to produce aircraft fuel ( alcohol-to-jet ). In 2014, the United States Army successfully tested the use of a helicopter with a fuel mixture of 50% petrochemical fuel and 50% fuel made from bio-based isobutanol.

On the question of whether n -butanol or isobutanol is more promising as a fuel of the future, opinions are divided. In any case, both isomers have some significant advantages over bioethanol :

- The butanols are less volatile than ethanol. This reduces the risk of outgassing, which is a safety advantage.

- The energy density of butanols is higher than that of ethanol. This means that fuel consumption is lower and the range is higher.

- The butanols have a higher viscosity than ethanol. This prevents abrasion problems in the engine compartment.

- With butanols, there are fewer ignition problems when starting cold than with ethanol, since the heat of vaporization is lower .

- The butanols can be mixed with gasoline in higher proportions without having to adjust the engine.

- Unlike ethanol, butanols can be transported in existing pipelines .

A disadvantage compared to the addition of ethanol in gasoline engines is that the octane number of the butanols - especially with n- butanol - is lower.

Individual evidence

- ↑ a b c d e f g h i j k l m n o p q r Wagner Roberto da Silva Trindade & Rogério Gonçalves dos Santos: Review on the characteristics of butanol, its production and use as fuel in internal combustion engines . In: Renewable and Sustainable Energy Reviews . tape 69 , 2017, p. 642–651 , doi : 10.1016 / j.rser.2016.11.213 .

- ↑ a b c d e f g h i j k Pamela P. Peralta-Yahya, Fuzhong Zhang, Stephen B. del Cardayre & Jay D. Keasling: Microbial engineering for the production of advanced biofuels . In: Nature . tape 488 , 2012, p. 320–328 , doi : 10.1038 / nature11478 .

- ↑ a b c Murat Karabektas & Murat Hosoz: Performance and emission characteristics of a diesel engine using isobutanol – diesel fuel blends . In: Renewable Energy . tape 34 , 2009, p. 1554–1559 , doi : 10.1016 / j.renene.2008.11.003 .

- ↑ This substance has either not yet been classified with regard to its hazardousness or a reliable and citable source has not yet been found.

- ↑ a b c Ashraf Elfasakhany: Investigations on performance and pollutant emissions of spark-ignition engines fueled with n-butanol–, isobutanol–, ethanol–, methanol–, and acetone – gasoline blends: A comparative study . In: Renewable and Sustainable Energy Reviews . tape 71 , 2016, p. 404-413 , doi : 10.1016 / j.rser.2016.12.070 .

- ↑ B. Ndaba, I. Chyanzu & S. Marx: n-Butanol derived from biochemical and chemical routes: A review . In: Biotechnology Reports . tape 8 , 2015, p. 1–9 , doi : 10.1016 / j.btre.2015.08.001 .

- ↑ Alexandra M. Goho: Better Bugs for Making Butanol - Engineered E. coli proves efficient at churning out the biofuel ; Technology Review ; January 16, 2008.

- ↑ Yuqiang Li, Wei Tang, Yong Chen, Jiangwei Liu & Chia-fon F. Lee: Potential of Acetone-Butanol-Ethanol (ABE) as Biofuel . In: Fuel . tape 242 , 2019, pp. 673–686 , doi : 10.1016 / j.fuel.2019.01.063 .

- ^ Peter Dürre: Fermentative Butanol Production - Bulk Chemical and Biofuel . In: Annales by the New York Academy of Sciences . tape 1125 , 2008, p. 353-362 , doi : 10.1196 / annals.1419.009 .

- ↑ Dianne J. Luning Prak, M. Hope Jones & Paul Trulove: Physical and Chemical Analysis of Alcohol-to-Jet (ATJ) Fuel and Development of surrogates Fuel Mixtures . In: Energy Fuels . tape 29 , no. 6 , 2015, p. 3760-3769 , doi : 10.1021 / acs.energyfuels.5b00668 . "

- ↑ a b c d e f Michael Köpke, Ryan E. Hill, Rasmus Ø, Jensen Dürre & Peter Dürre: Production of Biobutanol, from ABE to Syngas Fermentation . In: Xuefeng Lu (Ed.): Biofuels . tape 4 . Caister Academic Press, 2014, ISBN 978-1-908230-45-4 , pp. 137-162 .

literature

- Garabed Antranikian : Applied Microbiology , 1st edition, Springer-Verlag Berlin Heidelberg 2006, ISBN 3-540-24083-7 .

- Georg Fuchs (Ed.): General microbiology , founded by Hans-Günter Schlegel , 8th edition. Georg Thieme Verlag, Stuttgart, New York 2007, ISBN 978-3-13-444608-1 .

- Michael T. Madigan, John M. Martinko, Paul V. Dunlap, David P. Clark: Brock - Biology of Microorganisms , 12th Edition. Pearson, San Francisco et al. O. 2009, ISBN 0-321-53615-0 .

- Kevin Bullis: Cheap Butanol Made From Biomass ; Technology Review ; November 3, 2008.

Web links

- www.greencarcongress.com Biobutanol