Double sheet control

The double sheet control is a measuring and control system in printing technology . The double sheet testing comes into the single sheet feeders or dandruff investors of sheet-fed printing machine used. As soon as the double sheet control detects that two or more sheets (e.g. paper sheets) are being sucked in at the same time, the further transport of the double sheet is stopped in order to rule out consequential damage to the printing machine. The detection of double sheets can be done with contactless sensors ( ultrasonic , infrared or optical), but also mechanically or capacitively .

Double sheet inspection with ultrasound

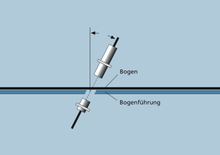

A high-frequency ultrasonic transmitter radiates from the lower side against the arch. The emitted signal stimulates the material to vibrate. These cause a very small sound wave to propagate on the other side of the arc, which is evaluated by the ultrasonic receiver opposite. If the sheets are on top of each other ("double sheet"), the signal is so weakened that it hardly reaches the receiver. The ultrasonic double-sheet control detects missing, single and double sheets.

With the ultrasonic double sheet control, different materials such as B. paper , foils , finest corrugated cardboard , thin metal sheets , wafers or thicker plastic films (e.g. credit cards) can be scanned. With papers and thin foils, the double sheet control is operated perpendicular to the material. In the case of fine corrugated cardboard, thin metal sheets, wafers or thicker plastic films, the double-sheet control must be mounted at a specific angle of inclination α to the material passing through.

- fine corrugated cardboard: α ≥ 35 °

- thin sheets or thicker plastic films: α = 27 °

- Wafer: α = 11 °

The ultrasonic double-sheet control was developed in 1999 by microsonic GmbH from Dortmund and was first used in the sheet-fed printing machines of Heidelberger Druckmaschinen AG . Since then, the area of application has expanded far beyond that of printing machines. The process is now also offered by other providers such as Leuze electronic .

Areas of application

- Sheet - fed printing machines

- Gathering machines

- Folding machines

- Paper converting machines

- Document processing machines

- ATMs

- Production of solar cells and silicon wafers

- Label processing

- PCB manufacturing

- Document scanner

Individual evidence

- ↑ Helmut Kipphan: Handbook of Print Media: Technologies and Production Processes . Springer, Berlin 2000, ISBN 3540669418 , p. 242.

- ↑ dbk + 4 double sheet control on the microsonic website. (Retrieved August 22, 2014.)

- ↑ 2009-02 Press release: dbk + 4 ultrasonic double sheet control on the microsonic website. (Retrieved March 12, 2010.)

- ↑ Double sheet control ( Memento of the original from February 13, 2010 in the Internet Archive ) Info: The archive link was automatically inserted and not yet checked. Please check the original and archive link according to the instructions and then remove this notice. on the Leuze electronic website. (Retrieved March 12, 2010.)