Liquid jet

A liquid jet is a directed jet of matter consisting of a liquid. Liquid jets come in various forms, e.g. B. continuous jets, droplet jets or sprays.

Continuous jets of liquid

A continuous liquid jet is understood to be a cylindrical liquid column that moves along the cylindrical axis. Such a jet can be generated, for example, by forcing a liquid to exit through a cylindrical opening with the diameter . Provided the exit speed of the liquid is above the minimum exit speed, a continuous liquid jet is formed.

Surface tension Beam radius density

This minimum exit speed for the generation of a continuous jet of liquid results from the energy balance between the energy required for the constant formation of the jet surface ( surface energy ) and the kinetic energy of the jet. The liquid drips off directly below the minimum exit speed.

The diameter of the generated liquid jet usually differs from the diameter of the opening / nozzle due to the relaxation of the jet profile. For laminar beams with a Reynolds number , the beam diameter decreases, while it increases for.

Ray decay of continuous rays

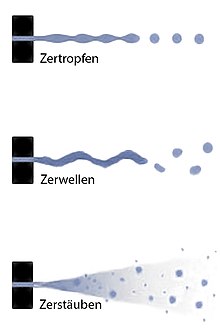

A continuous jet of liquid is unstable to natural and artificial disturbances and disintegrates after a certain disintegration time . The distance between the disintegration point and the nozzle, called the disintegration length , therefore depends on the disintegration time and the jet speed . The type of disintegration depends on the material properties of the liquid, the flow conditions in and after the nozzle as well as the surrounding fluid. The disintegration of the continuous liquid jet is known as primary disintegration. In contrast to this, the disintegration of the resulting fragments (e.g. droplets) is called secondary disintegration, and this can be repeated until the fragments have reached a stable state. The primary decay is divided into different decay areas by Ohnesorge and von Haenlein:

- Dripping : Slow dripping from the nozzle without creating a continuous jet.

- Droplet : disintegration of a cylindrical jet due to axially symmetrical surface vibrations . Haenlein also divides this area into the areas “droplets without air influence” and “droplets with air influence”.

- Undulation : disintegration due to screw- symmetrical oscillations of the jet mass.

- Atomization : atomization of the jet.

In the English-language literature, one finds the division of the decay areas into the areas of Rayleigh breakup , first wind-induced regime , second wind-induced regime and atomization regime . This classification follows the classification already made by Ohnesorge and Haenlein, but the use of the term wind-induced emphasizes the importance of the surrounding fluid (see picture of decay ranges: decay length versus jet speed ).

Drop

When it drops, the continuous jet of liquid breaks up into a jet of droplets consisting of drops with a diameter in the order of magnitude of the jet diameter. The jet disintegration is characterized by axially symmetrical disturbances, which cause the jet to break up into drops. This decay area is divided into the areas of Rayleigh breakup (“without air influence” at Haenlein) and first wind-induced regime (“with air influence” at Haenlein).

Without environmental / air influence (Rayleigh breakup)

The Rayleigh breakup area is named after Lord Rayleigh, who was the first to provide a comprehensive mathematical description of the phenomenon. In this area, small disturbances of the jet surface initially grow, driven by the surface tension, up to the jet radius and thus lead to the detachment of a drop from the continuous jet. Since Joseph Antoine Ferdinand Plateau had already identified a stability limit for this type of beam decay, this instability of the beam is called Plateau-Rayleigh instability . An interaction with the surrounding gas does not play a role here.

Lord Rayleigh simplifies the problem for his theoretical consideration by disregarding viscosity, gravity and the ambient fluid and also assuming an infinitely long cylindrical jet. He succeeds in calculating the growth rates of the disturbances depending on their wavelength. Donnelly & Glaberson, who study the growth rates experimentally, find a good agreement between their experimental results and Rayleigh's growth rates. For the fastest growing perturbation, Rayleigh determines the optimal wavelength and the associated optimal growth rate for non-viscous rays as follows:

Rayleigh also investigates the case of a viscous jet, but comes up with an impractical, complicated solution. Only Weber takes a more practical solution to the decay of a viscous jet. So he finds the following relationship for the optimal wavelength of a viscous jet:

According to Weber, the following applies to the corresponding growth rate of a viscous jet of the optimal wavelength:

It can be seen from the formula that the optimum growth rate decreases with increasing viscosity, while it can be seen from the previous formula that the optimum wavelength increases with increasing viscosity. Rayleigh's and Weber's approaches no longer apply near the point of decay, since the assumption of small disturbances is no longer applicable there. For this reason, phenomena such as satellite droplets cannot be explained using these approaches; non-linear models must be used for this. The disintegration length of the jet (theoretical disintegration length) results from the disintegration time (theoretical disintegration time) and the jet velocity . Whereby the following applies to the disintegration time according to Weber:

And thus:

As can be seen from the formula, the decay length in this area increases linearly with the jet speed. describes the initial disturbance amplitude and is usually not known. However, it can be determined from the filament length using the formula above. In most publications, however , the logarithmic ratio is not given, instead . Weber determined a value of 12 for this ratio from Haenlein's data. Grant & Middleman show that the ratio must be dependent on the number of children without care, and state the following relationship for their data:

This relationship shows that the initial interference amplitude must increase for small beam radii and, consequently, a larger number of no-worries. Since natural disturbances are subject to fluctuations in terms of their wavelength and amplitude, the natural length of decay and the size of the droplets formed also fluctuate around an average value.

If no ambient gas is present, this decay range expands to higher Reynolds numbers, since the interaction with the ambient gas is eliminated. With higher Reynolds numbers, however, the influence of the internal disturbances increases (e.g. relaxation of the jet profile, cavitation and turbulence), which can lead to a deviation from the linearly increasing decay time.

With ambient / air influence (first wind-induced regime)

Above a certain critical jet speed , the decay length no longer grows linearly , reaches a maximum at or and then drops. Haenlein explains this with the influence of the surrounding gas (air). He assumed that the air above the wave crest moves faster than above the wave trough and that this creates different pressure areas, which lead to an intensification of the wave movement and the constriction. Weber considers, with the help of the experimental work of Haenlein, the influence of the ambient gas from the theoretical side. It shows that with increasing ambient gas density, the growth rates for the disturbances increase and the optimal wavelength shifts to smaller values. However, other works seem to show that the influence of the ambient gas does not contribute to the formation of the maximum to the extent that Haenlein and Weber assume.

Smith & Moss have already observed earlier through the use of a nozzle with a very small ratio that the maximum only forms with significantly higher Reynolds numbers than with the nozzles usually used by them with the same nozzle radius. These commonly used nozzles consist of a narrowing glass tube with a cylindrical outlet, while the nozzle with a very small ratio consists of a hole in a thin metal plate. They suspect that the reason for the earlier occurrence of the maximum in their glass nozzles is that turbulence is generated due to a stronger relaxation of the velocity profile (see Section 2.1.4). McCarthy & Molloy mentions other work that comes to similar conclusions as Smith & Moss. Sterling & Schleicher analyze experimental data from jets in which a relaxation of the jet profile is reduced (nozzles with ) in order to clear up the fact that Weber's theory overestimates the influence of the ambient gas. You also consider the experimental data from Fenn and Middleman, who found a dependency on the viscosity of the ambient gas. Sterling & Schleicher finally succeeds in formulating a corresponding modified Weber theory by including the viscosity of the ambient gas, which fits well with the experimental data, provided that the relaxation of the jet profile does not become dominant.

Fenn and Middleman determine a critical Weber number for the ambient gas , below which the liquid jet has no effects that can be caused by the ambient gas present. To determine this critical Weber number, investigate the critical speed at which the relationship between jet length and speed loses its linear dependence.

Sterling & Schleicher find a dependency of the critical Weber number on the number of no care. A fit of your data provides the following relationship:

From this it follows that the influence of the ambient gas for smaller nozzle diameters or a higher viscosity of the liquid only sets in at higher jet speeds.

Due to the shorter optimal wavelength, the natural jet decay produces smaller droplets in this area (with environmental influence) than in comparison to the dropping without environmental influence, but still in the order of magnitude of the jet diameter. In addition, the size distribution of the drops that result from the natural break-up is broader here, and satellite drops are also increasingly formed. Wave-like disturbances can sometimes be observed here, but they do not yet dominate the decay mechanism.

Satellite drop

In addition to the main droplets that arise from the interference wavelength, under certain circumstances smaller droplets are formed during excited droplets, which lie between these main droplets and are called satellite droplets. They originate from non-linear instabilities. There is a large number of works that deal with non-linear models of beam break-up, which are not discussed in detail here. When considering non-linear instabilities, one finds that there are also higher harmonics of the initial disturbance, which, however, only become significant very shortly before the point of decay. They can lead to the formation of ligaments between the bulges. These bands then contract to form the satellite drops, and more than one satellite drop can emerge from the bands. With a fixed, initial disturbance amplitude, the size of the satellite droplets depends on the Ohnesorge number, the Reynolds number and the wavelength. For Oh> 0.1 the satellite size decreases with decreasing Reynolds number. For Oh <0.1, however, the Reynolds number no longer has any significant influence on the satellite size. One also observes that the satellites and the main droplets get smaller when the wavelength decreases, whereby the change in size for the satellites is more pronounced (see Figure 2.6, center). The non-linear observation shows that the maximum of the growth rate in the case of no-care numbers below a value of about 1 is shifted to smaller wavelengths (larger wave numbers) (see Figure 2.6 left). There is also a range depending on the number of unconcerned, the wavelength and the initial interference amplitude in which no satellites are created (see Figure 2.6 right). The satellite drops are often undesirable in the application. If they do not fuse with the front or rear main droplet on their own after their formation, there are different approaches to avoid satellite droplets. On the one hand you can try to avoid the formation of the satellites directly, on the other hand you can try to get the resulting satellites to merge with the main droplets and finally there is also the possibility of charging and deflecting the unwanted droplets. To avoid the creation or merge the satellites, a perturbation with a more complex waveform can be created. For example, a modulated speed disturbance consisting of two frequencies (the first and third harmonics) at a certain ratio of the initial disturbance amplitude of these two frequencies can prevent satellite formation. Modulated perturbations can also be used to promote merging. In the case of monochromatic interferences, there can also be a merging, but modulated interferences accelerate this process. Vassallo et al. found that with the same ratio of and the same Weber number, but smaller nozzle diameter, the area in which no satellites are formed or immediately merge with the main droplet is larger. They also found that stable satellites are no longer observed above a certain interference amplitude. Figure 2.5 shows examples of a jet of droplets excited in different ways.

Stimulated disintegration

A naturally dripping liquid jet usually creates drops of different sizes with different distances between them. For the application, however, a uniform droplet jet, ie with constant droplet size, constant spacing and constant speed, is decisive. The constant speed can be achieved by a constant nozzle pressure . In order to achieve a constant droplet size and a constant droplet spacing, the natural disturbances can be superimposed by an artificial, external disturbance. Savart already observed that externally applied vibrations have an influence on a liquid jet and its disintegration. One of the first devices to use a vibrating nozzle (glass capillary tube) comes from Dimmock. Schneider & Hendricks later used a piezoelectric vibration transmitter to give a mechanical vibration axially to their nozzle (capillary tube). There are several methods by which an external disturbance can be imposed on the ray, e.g. B.

- by a vibrating surface within the liquid volume of the nozzle;

- by the diaphragm which is excited to vibrate and also serves as a nozzle;

- by inducing acoustic waves using a loudspeaker.

- or the disturbance is only applied after the generation of the beam, e.g. B. by a vibrating needle, the tip of which lightly touches the beam.

Nowadays a piezo element is mostly used, which is attached to the nozzle body. Due to the inverse piezoelectric effect, the piezo element generates a mechanical oscillation from an applied electrical oscillation, which in turn causes the disturbance of the beam. It makes sense to choose the excitation frequency that generates a disturbance with the wavelength that grows fastest (2.5). From this it follows for a given liquid:

For

The excitation frequency must therefore increase when the beam speed increases or the beam radius decreases. This also applies if the optimal Weber wavelength is used instead of Rayleigh, but the proportionality of the frequency to the beam diameter is different.

Similar information can be found in the literature for the position of the wavelength range at which a uniform jet of droplets is created. The differences in the information are mainly in the breadth of the range. The smallest is included , the largest included . Brenn et al. show that both limits become smaller as the flow velocity increases, with the lower limit decreasing more. You also observe that the area becomes larger for smaller nozzles, this being done only by the smaller the lower limit. According to Berglund, the beam is no longer uniform (e.g. satellites are formed) if the wavelength is too large and for wavelengths that are too small, the excitation no longer seems to have any effect on the beam. It also shows that the wavelength range shrinks as the interference amplitude decreases. Vassallo & Ashgniz experimentally investigate how the droplets of excited water jets ( 120–620 µm) differ at different wavelengths. You will find four areas that are defined by the ratio of the wavelength to the beam diameter: for there is an irregular beam break-up , for a regular break-up without satellites, for a regular break-up with satellites that are stable or merge with the main droplets (this depends on the Disturbance amplitude), for regular break-up, but here each period consists of more than one drop, these can be the same size or different sizes. They also mention that the 2nd area is wider for small beam diameters, because the smaller the beam diameters, the less likely a satellite drop will become detached from the filament.

Ripple

If the flow velocity is increased even further for a given ambient gas density, the increased influence of the ambient gas leads to undulations, which means that wave-like disturbances now dominate. The beam cross-section does not change here; instead, there are small deflections from the beam axis. With viscous jets, this leads to a wave-like appearance. On the other hand, with slightly viscous jets there is no strong expression of this wave-like appearance, instead smaller liquid particles are thrown off, which form a conical jacket around the jet.

The surface tension counteracts the rippling, as it tries to return the beam to its original position with the smallest surface. The spectrum of disturbances that lead to disintegration here is larger, so that the size distribution of the drops or fragments becomes wider than when the drops or fragments are broken up under the influence of the environment. The disintegration of the continuous jet not only leads to the formation of droplets, longer fragments can also become detached. The use of short nozzles can lead to an increase in the disintegration length.

atomization

When atomizing, the continuous jet is completely dissolved. Drops are created that are much smaller than the jet diameter and the size distribution of the droplets is very broad. The point of atomization can reach as far as the nozzle outlet, so that a continuous jet of liquid does not even form, and a clear divergence can usually be observed from the point of disintegration. Causes of atomization can include:

- the onset of cavitation within the nozzle,

- the relaxation of the velocity profile,

- the turbulence of the jet,

- the interaction with the ambient gas,

- the liquid in the nozzle is supercritical .

The way in which the atomization takes place can be very different due to various causes (e.g. liquid fragments torn off the jet surface due to the interaction with the ambient gas or the jet suddenly ripped apart due to internal turbulence). Therefore, the course of the stability curve for this area is not clear in the literature. It is also difficult to determine which effect is currently decisive for the decay. The nozzle geometry plays an even more decisive role in this area than it already does in the other decay areas. The use of special nozzles can ensure that the liquid comes out of the nozzle already atomized. While the use of short cylindrical nozzles leads to an increase in the disintegration length, in particular in this area with such nozzles the use of a "hydraulic flip" can suddenly increase the disintegration length.

application

Liquid jets are used in a wide variety of areas. In everyday life you can find them e.g. B. Coming from the tap , the shower head and spray cans. In agriculture, they play a role in irrigation and the application of pesticides . In the medical field one encounters liquid jets e.g. B. during injection procedures or inhalers . The industry uses liquid jets as a cutting tool , for coating materials or, for example, in cooling towers . Atomizing liquid jets are essential for the efficiency of internal combustion engines . But they also play a decisive role in research, for example in the investigation of proteins , phase transitions , extreme states of matter, laser plasmas, but also in experiments in particle physics .

Individual evidence

- ^ NR Lindblad, JM Schneider: Production of uniform-sized liquid droplets . In: Journal of Scientific Instruments . tape 42 , no. 8 , 1965, p. 635 - 638 , doi : 10.1088 / 0950-7671 / 42/8/338 .

- ↑ a b c Dumouchel, Christophe: On the experimental investigation on primary atomization of liquid streams . In: Exp. Fluids . tape 45 , 2008, p. 371-422 .

- ↑ Wolfgang V. Ohnesorge: The formation of drops at nozzles and the dissolution of liquid jets . In: ZAMM - Journal for Applied Mathematics and Mechanics . tape 16 , no. 6 , 1936, pp. 355–358 , doi : 10.1002 / zamm.19360160611 .

- ↑ a b c Haenlein, A .: On the disintegration of a liquid jet . In: Research in Engineering . tape 2 , no. 4 , 1931, p. 139-149 .

- ↑ a b Lin, SP; Reitz, RD: Drop And Spray Formation From A Liquid Jet . In: Annu. Rev. Fluid Mech. Band 30 , 1998, pp. 85-105 .

- ↑ Lord Rayleigh, John William Strutt: On The Instability Of Jets . In: Proceedings of the London Mathematical Society . tape 10 , 1878, p. 4-13 .

- ^ Plateau, JAF: About the limits of the stability of a liquid cylinder . In: Ann. Phys. Chem. Band 80 , 1850, pp. 566-569 .

- ↑ Donnelly, RJ; Glaberson, W .: Experiments on the Capillary Instability of a Liquid Jet . In: Proc. Roy. Soc. London A . tape 290 , no. 1423 , 1966, pp. 547-556 .

- ↑ Lord Rayleigh, JWS: On the Instability of a Cylinder of Viscous Liquid under Capillary Force. In: Phil. Mag. Band 34 , no. 207 , 1892, pp. 145-154 .

- ↑ Weber, Constantin: To the disintegration of a liquid jet. In: Journal for Applied Mathematics and Mechanics . tape 11 , no. 2 , 1931, p. 136-154 .

- ↑ a b c Grant, Rollin Peter; Middleman, Stanley: Newtonian Jet Stability . In: AI Ch. E. Journal . tape 2 , no. 4 , 1966, pp. 669-678 .

- ↑ a b Sterling, Arthur M .; Sleicher, CA: The instability of capillary jets . In: J. Fluid Mech. Volume 68 , 1975, pp. 477-495 .

- ↑ a b c Fenn, Robert W .; Middleman, Stanley: Newtonian Jet Stability: The Role of Air Resistance . In: AlChE Journal . tape 15 , no. 3 , 1969, p. 379-383 .

- ^ Smith, SWJ; Moss, H .: Experiments with Mercury Jets . In: Proc. R. Soc. Lond. A . tape 93 , 1917, pp. 373-393 .

- ↑ McCarthy, MJ; Molloy, NA: Review of Stability of Liquid Jets and the Influence of Nozzle Design . In: The Chemical Engineering Journal . tape 7 , 1974, p. 1-20 .

- ↑ Ashgriz, Nasser: Handbook of Atomization and Sprays . Springer, 2011, ISBN 978-1-4419-7264-4 , pp. 20-28 .

- ↑ a b Ashgriz, N .; Mashayek, F .: Temporal analysis of capillary jet breakup . In: J. Fluid Mech. Volume 291 , 1995, pp. 163-190 .

- ↑ Chaudhary, KC; Maxworthy, T .: The nonlinear capillary instability of a liquid jet. Part 3. Experiments on satellite drop formation and control . In: J. Fluid Mech. Volume 96 , no. 2 , 1980, p. 287-297 .

- ↑ a b Vassallo, P .; Ashgriz, N .: Satellite Formation and Merging in Liquid Jet Breakup . In: Proc. R. Soc. Lond. A . tape 433 , 1991, pp. 269-286 .

- ↑ unknown: Excerpt from a treatise by Mr. Savart on the nature of the jets of liquid that shoot out of circular openings in thin walls. In: Ann. Phys. tape 105 , 1833, pp. 353-356 .

- ^ Dimmock, NA: Production of Uniform Droplets . In: Nature . tape 166 , 1950, pp. 686-687 .

- ↑ a b Schneider, JM; Hendricks, CD: Source of Uniform-Sized Liquid Droplets . In: Rev. Sci. Instrum. tape 35 , 1964, pp. 1349-1350 .

- ↑ a b c Berglund, Richard N .; Liu, Benjamin YH: Generation of Monodisperse Aerosol Standards . In: Environ. Sci. Technol. tape 7 , 1973, p. 147-153 .

- ↑ a b Donnelly, RJ; Glaberson, W .: Experiments on the Capillary Instability of a Liquid Jet . In: Proc. Roy. Soc. London A . tape 290 , no. 1423 , 1966, pp. 547-556 .

- ↑ a b Brenn, Günter; Thirst, Franz; Tropea, Cameron: Monodisperse Sprays for Various Purposes - Their Production and Characteristics . In: Part. Part. Syst. Charact. tape 13 , 1996, pp. 179-185 .

- ↑ Brenn, Günter: On the controlled production of sprays with discrete polydisperse drop size spectra . In: Chemical Engineering Science . tape 55 , 2000, pp. 5437-5444 .

- ↑ H. Vahedi Tafreshi, B. Pourdeyhimi: Cavitation and hydraulic flip . In: Fluent News . tape 13 , no. 1 , 2004, p. 38 .

- ↑ Frauke Bierau et al .: Catching Proteins in Liquid Helium Droplets . In: Physical Review Letters . tape 105 , no. 13 , 2010, p. 133402 , doi : 10.1103 / PhysRevLett.105.133402 .

- ^ Matthias Kühnel et al .: Time-Resolved Study of Crystallization in Deeply Cooled Liquid Parahydrogen . In: Physical Review Letters . tape 106 , 2011, pp. 245301 , doi : 10.1103 / physrevlett.106.245301 .

- ↑ Neumayer, P et al .: Evidence for ultra-fast heating in intense-laser irradiated reduced-mass targets . In: Physics of Plasmas . tape 19 , 2012, p. 122708 , doi : 10.1063 / 1.4772773 .

- ^ RA Costa Fraga et al .: Compact cryogenic source of periodic hydrogen and argon droplet beams for relativistic laser plasma generation . In: Review of Scientific Instruments . tape 83 , 2012, p. 025102 , doi : 10.1063 / 1.3681940 .

- ^ Gianluigi Boca: The PANDA experiment: physics goals and experimental setup . In: EPJ Web of Conferences . tape 72 , 2014, p. 00002 , doi : 10.1051 / epjconf / 20147200002 .

![{\ displaystyle \ mathrm {[N / m]}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/b6f34678d72ed9e97f97af2521ed8a617c4ca190)

![{\ displaystyle \ mathrm {[m]}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/d737b1d2dada4bf5bf353dc047d83fa5ce528824)

![{\ displaystyle \ mathrm {[kg / m ^ {3}]}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/ef6c1e9ed5d269cd5141ec280e4759dfd077e566)

![{\ displaystyle \ mathrm {[Pa \ cdot s]}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/dab98cc693fa02adb4e921839b061cf40538854f)