Free fall system MC-3

The MC-3 free fall system of the American armed forces was used intensively by special units of all branches of the armed forces until the 1980s . It was used for the vertical movement of small groups into enemy-controlled areas in the HALO procedure and was first used during the Vietnam War . In addition to the main and reserve parachutes , the free fall system also included the oxygen supply , the automatic opening device and the harness. The main parachute was based on the civilian Para-Commander - the first high-performance round canopy from the 1960s .

history

Until the early 1960s, the military and the first civilian sport jumpers jumped with the basically unchanged round-cap parachutes, which had been used in major airborne operations 20 years earlier . However, soon after the Second World War , the military was looking for a way to give their soldiers a controllable parachute, in which fields and panels were cut out of the parachute canopy at the back and sides and control lines led to the side slits. These parachutes, known as MC (Maneuverable Canopy) by the American military, were only introduced to a limited extent because they were unsuitable for jumping in a row from low heights. For this reason, the controllable umbrellas were reserved for smaller units with a special order.

At the same time, parachuting became an important factor in parachute development worldwide . Freefall jumps and target jumps with the most accurate landings possible have so far only been carried out with parachutes that you have modified yourself from military stocks. In 1961 the Frenchman Pierre Lemoigne presented his revolutionary development of a heavily modified round canopy. Over a dozen specially shaped openings and slits changed the aerodynamics so much that this glider could even be pulled into the air from the ground - from which later parasailing emerged . The American parachute manufacturer Pioneer Parachute Inc. from Connecticut became aware of this new development and developed it into a jump parachute especially for the civilian market. In 1963, this parachute, known as Para-Commander, was first presented to the public. With an almost doubled glide ratio of 1: 1, and very good control and landing properties, it was by far superior to the parachutes previously used, whereupon almost all sport jumpers used the Para-Commander within a few years. As early as 1966, for example, all participants in the American state championships in parachuting jumped with this high-performance parachute.

Para-commander

For more than 10 years Pioneer has produced the Para-Commander with various modifications for heavier jumpers or especially for competitions. However, these versions were not produced anywhere near the same numbers as the Mark I, which never lost its popularity due to its good control characteristics and pleasant sink rate. The canopy of the Para-Commander Mark I, measuring 7.3 m in diameter, consisted of 24 panels with 24 suspension lines. The apex of the parachute canopy was closed and was pulled down by an additional suspension line running to the harness. This construction, known as apex-down , encouraged full deployment and stabilized the shape of the parachute. In addition, the front edge was higher than the rear half of the Para-Commander, which meant that the air resistance could be reduced when driving forward and the 17 rear slots could be flown evenly against. These were overlapping and shaped in such a way that the escaping air did not flow mainly upwards, but backwards and thus a more forward force acted on the parachute. As a result, the Para-Commander achieved a forward speed of a maximum of 21 km / h with a previously unattained glide ratio of 1: 1. His steering skills were equally impressive. On each side the canopy had four narrow, differently sized control slots that the jumper could close by pulling on the control lines and thereby turning or braking the parachute.

Compared to the round caps of that time, the Para-Commander had a more elliptical basic shape due to the stabilizers on the side. The stabilizers sewn into five strips on each side under the actual parachute canopy reduced the swing of the wing, especially during steering maneuvers. Despite the comparatively small diameter, the Para-Commander had a low sink rate due to its aerodynamic advantages and the low air permeability of the material used, which was around 5 m / s depending on the load. From 1977 the Mark I was made of lighter and airtight rip-stop nylon fabric, which increased the glide ratio slightly, reduced the sink rate slightly and reduced the weight of the canopy from 7.3 kg to 5.6 kg.

The Para-Commander was developed as a free-fall parachute with manual opening. However, it was also possible to integrate an automatic opening device that automatically opened the parachute when the set height was reached. Most civilian jumpers still carried the reserve umbrella in the form of a non-controllable round cap in front of the chest. Only a few jumpers used a so-called piggyback with which the reserve umbrella was carried under the main umbrella. Although the Para-Commander has been superseded by the far superior wing parachutes for almost all sport jumpers for many years, some enthusiasts still jump it to this day.

Flight characteristics

The flight and control properties shown for the first time by the Para-Commander are mainly based on the control slots on the sides. Unlike the previously used openings on the base edge, the slots were cut out of four adjacent strips. By increasing the tension on the control lines, the air flow from the slots could first be slowed down and then reversed. This not only enabled faster turns, as opposing forces acted on the opposite sides, but the parachute could also be braked because the air flow on the sides canceled the propulsion from the rear openings of the canopy. Thus, it was possible to turn the Springer the Para-Commander in just three seconds or down in its forward movement to a stall to brake, in which the rate of descent doubled without unstable or become uncontrollable. In order to be able to steer his wing safely and to the fullest extent possible, the jumper had to master five flight conditions. These ranged from full speed to controlled stall and each had its own purpose in target jumping.

Full speed : During this fastest possible forward drive , there was no pull on the steering lines and was used if this was the only way to reach the landing point. The Para-Commander tended to get very restless and fluctuated quite a lot when turning.

Half brake : The control lines were pulled at about chin height. During this controlled forward movement, the parachute was calm and turned quickly but still softly and was therefore particularly suitable for canopy formation flying.

Full brake : With the control lines at chest height, the parachute sank very steadily with a glide angle that was particularly suitable for the final approach when target jumping.

Sink : If the jumper pulled the steering lines a little further, the Para-Commander only sank at an increased rate of descent. This allowed height to be reduced quickly. In order to maintain a longer sink, the jumper had to slowly increase the tension of the steering lines.

Stall : Just a little below the sinking position was the control line position for the stall, which took a few seconds to set in. The parachute jerked back a little before continuing to sink at increased speed. A trained jumping could switch back and forth between stall and sinking and so go backwards with the glider.

| maneuver | Forward speed | Rate of descent | Glide ratio |

|---|---|---|---|

| Full speed | 4.5 m / s | 4.5 m / s | 1: 1 |

| Half brake | 2.7 m / s | 5.5 m / s | 0.5: 1 |

| Full brake | 1 m / s | 6.4 m / s | 0.15: 1 |

| Sink | 0 m / s | 7.6 m / s | 0 |

| barn | −0.6 m / s to 0 m / s | 7.6 m / s to 9.1 m / s | 0 |

The table shows the flight conditions and speeds when there is no wind in a summarized form. Even an experienced jumper needed a few flights with the Para-Commander before he could safely steer it and know the position for the sink and stall. Especially shortly after the introduction of the Para-Commander, many underestimated the new dynamic, which led to many hard landings.

Because of the asymmetrical shape and the larger number of lines and openings, the Para-Commander was a little more prone to incorrect openings than a "normal" round canopy. Most of them could be fixed quickly by the jumper with a strong pull on the control lines, but the parachute often began to circle quickly due to the built-in propulsion if the canopy was not opened properly. Because opening the reserve parachute in such a situation usually resulted in it becoming entangled in the main parachute, the main canopy had to be separated first. For this emergency procedure, which is new for parachutists, the cap locks on the two main risers were used.

Military use

After the Para-Commander Mark I had become the predominant parachute model among American sport jumpers within a few years, the US military also became interested in this parachute. Its flight characteristics made it particularly interesting for special forces that had had experience in military free-fall jumping in the American army since 1957 . So far they used the military parachutes of the MC1-1 series, which only had a glide ratio of 0.7: 1. In contrast, the Para-Commander, with its superior glide ratio and target flight properties, made it easier for jumpers to reach the landing zone in a closed group. Before the military carried out the first official tests with the Para-Commander, some freefall jumpers from the Air Force Academy (USAFA) Parachute Club had already procured it and jumped from Air Force aircraft and helicopters with it. A similar development happened in Germany, Great Britain, Canada and with the US Army , where military demonstration groups jumped with this parachute during competitions or in front of an audience.

In 1966 the US Air Force then tested the Para-Commander Mark I for possible military use. Thereby, 246 puppet drops and test jumps were carried out from various aircraft and helicopters and the suitability of the parachute for well-trained free-fall jumpers was proven. This began the integration of the Para-Commander into the military free fall system MC-3 of the American armed forces. The US Air Force were the first to introduce the Para-Commander for Combat Control Teams (CCT) . In the 1970s , the US Army and Navy also took over the para-commander for their special forces freefall jumpers .

The first combat mission with civilian Para-Commanders was carried out by the US Army during the Vietnam War in 1971. After 3 previous HALO missions with increasing success, the soldiers jumped with the Para-Commander for the first time in September. This free fall operation took place at night in enemy territory and the small group managed to land closed without injuries, carry out their reconnaissance mission and return to the base.

The training in parachuting with the MC-3 system based on the Para-Commander took place at different locations depending on the armed forces. The last freefall course with the MC-3 was held in 1986 with the US Army. After that, the training was switched to the wing parachutes of the MT-1 series, which, due to their construction, had significantly better flight characteristics. Nevertheless, the MC-3 parachute remained in use by some units of the National Guard and the reserve units until the 1990s , where no retraining for the new generation of parachutes had taken place.

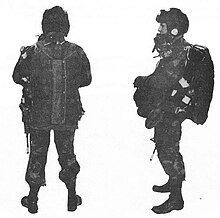

Free fall system MC-3

The complete free fall system MC-3 comprised the main assemblies:

- Main parachute with packing tube (inner packaging)

- Reserve umbrella

- Helmet with mask and oxygen system

- Harness with container (outer packaging)

The main parachute consisted of the parachute canopy with packing tube and (opening) auxiliary parachute, the container, the harness with the opening handle and the automatic opening device. The parachute canopy corresponded to the Para-Commander Mark I in terms of size, material and flight characteristics. For military use, the material was only supplied in a camouflage pattern or a dark shade.

The container was attached to the harness, which contained the main canopy with the packing tube and the spring-loaded auxiliary parachute. This was released as soon as the jumper pulled the handle, which was on the right front of the harness at chest height, and the three or four locking pins released the flaps of the packing case. Several elastic straps on the outside of the packaging sack then pulled back the flaps to help the parachute unfold. While the main canopy of the civilian versions could also be packed in a short packing tube or a POD, all military para-commanders were delivered with a packing tube to which the auxiliary parachute was attached. The auxiliary parachute stretched the packing tube in order to then unwind the suspension lines from the packing rubbers before the parachute canopy was pulled out of the packing tube and unfolded fully.

Two leg straps and a chest strap, each fastened with a quick release, held the jumper in the harness, which was adjustable at 3 points. Two D-rings at chest height were provided for attaching the reserve umbrella. There were two more fastening belts on the seat belt, to which the lowering line was attached when jumping luggage. A pocket on the lower left back strap was provided for the opening machine, from which a cable hose ran to the packing case. In addition, the jumper was able to connect his oxygen mask to the aircraft's oxygen supply or to his own oxygen bottle using a connector on the left above the chest strap.

The oxygen supply for height jumps over 4000 m was ensured for a maximum of 15 minutes from two small oxygen bottles with an off switch and pressure indicator. The oxygen bottles were carried in a pocket under the reserve umbrella. The oxygen flowed through the connector into the mask, which was connected with two bayonet locks to the helmet, also known as MC-3, and which could also accommodate a microphone for the dropper.

A small instrument panel with an integrated altimeter was attached to the top of the reserve parachute. Different types have been used over the years. What they had in common was a display illuminated with red light that could be turned on and off via a switch. Later, the more practical altimeters for the wrist were also issued. As a safeguard, the MC-3 system has an automatic opening device in case the jumper failed or was not able to open the main umbrella in time. Before jumping, the jumper sets the minimum opening height above the landing zone as an air pressure value in millibars or a time delay after jumping. In an emergency, the automatic opening device called FF-2 pulls the locking pins out of the packing sleeve of the main umbrella via the built-in spring.

The opening process usually took 2.5 seconds and gave the jumper a relatively strong opening push, which became greater the more equipment the soldier wore. Including the harness, a maximum of 160 kg was allowed to hang under the MC-3 parachute. The soldier carried his equipment under the main umbrella in a backpack, which was lowered on a rope before landing. His handgun was attached separately to the side of the body.

Technical specifications

| Parameter | |

|---|---|

| Cap diameter | 7.3 m |

| Line length | 6.4 - 6.8 m |

| Tensile strength per suspension line | 250 kg |

| Sink speed with 86 kg load | 4.7 m / s |

| Descent speed with a load of 113 kg | 5.4 m / s |

| Max forward speed | 21 km / h |

| Glide ratio | 1: 1 |

| Rotation speed (360 °) | 3 s |

| Parachute canopy weight | 7.2 kg |

Individual evidence

- ^ Gary Lewis: Para-Commander Handbook , 1978, p. 3

- ^ A b c Gary Lewis: Para-Commander Handbook , 1978, p. 4

- ^ Dan Poynter: The Parachute Manual: A Technical Treatise on Aerodynamic Decelerators , Volume 1, Para Publishing, Santa Barbara, CA, 1991 p. 124

- ^ Gene Adcock: CCT - The Eye of the Storm , Combat Control School Historical Foundation, 2009 p. 132

- ^ Charles W. Nichols: Performance Evaluation of Para-Commander Mark 1 Personnel Parachute , Air Force Flight Test Center, Edwards AFB, CA, 1966

- ↑ Sam Brasfield: Innovations in air insertion (involving parachutes) , Naval Post-Graduate School, Monterey, 2008, p. 91

- ↑ Field Manual 31-19: Military Free-Fall Parachuting , Washington DC, 1993, SA-1

literature

- Field Manual 31-19: Special Forces Military Free-Fall Parachuting , Washington DC, 1977

- Field Manual 31-19: Military Free-Fall Parachuting , Washington DC, 1993

- Robert J. McLaughlin: An Analysis of Personnel Parachutes for Use by Marine Corps Force Reconnaissance Units , Naval Postgraduate School, Monterey, CA, 1977

- Gary Lewis: Para-Commander Handbook , 1978