Reefer container shipping

In the cooling container shipping was used in the container services with a high cooling load share initially in a north-south direction cooling rods for Porthole refrigerated containers . The east-west services, on the other hand, use integral refrigerated containers . Until 1995, refrigerated container ships were built with cooling rods. The last newbuildings were delivered for the Aliança shipping company , a subsidiary of Hamburg Süd , for the South American service. Today only integral refrigerated containers are used in reefer shipping. The ships of the Monte and Rio class of the Hamburg Süd shipping company currently have the largest refrigerated container capacity with spaces for around 2500 TEU integral containers. There is a very small group of ships such as B. the Puritan , which the name suggests that they only transport refrigerated containers.

Conversion of the route to refrigerated containers

The previously constantly growing costs of liner shipping for general cargo was caused by general cargo handling . The handling of the various sizes, packaging and weights of the individual piece goods was time-consuming and extremely labor-intensive. In order to avoid the necessary transport, interim storage and transshipment processes, the piece goods had to be standardized. With the container, a standardization in a 20-foot grid was achieved, the desired bulk cargo character could be realized and in addition to the homogenization of the cargo, the general cargo received effective protection against weather and theft. This was especially true for the extremely sensitive refrigerated cargo. The handling could be carried out much faster with the container and, thanks to the mechanization, with considerably fewer personnel.

The term refrigerated container ship is not clearly defined. All container ships with more than 50 sockets for refrigerated containers are often referred to as refrigerated container ships. Other definitions only designate container ships with cooling rods as refrigerated container ships.

The following definitions have been proposed to clarify the term:

- TEU = 20 foot unit

- R-TEU = Reefer TEU

- PR-TEU = Porthole Reefer TEU

- IR-TEU = Integrated Reefer TEU

- Refrigerated ship = all holds are insulated and can be cooled

- Refrigerated container ship = container ship with more than 50 R-TEU (Drewry)

The principle of installing a system of refrigeration systems and cooling rods in the hold to connect porthole refrigerated containers was developed in Europe when the Australian liner service was converted to containers quite abruptly in 1969. Before that, liner cargo ships with a large proportion of cold storage were used in this service . Long lay times, ongoing strikes in Australian ports and a high proportion of cargo theft were reasons for the rapid containerization.

The new ships in this pioneering phase from 1969 to 1978 were necessary to containerize new shipping areas in north-south traffic with a medium (20 to 30 percent) or high proportion of refrigerated cargo (greater than 50 percent). The newbuildings that were put into service after 1980 are mostly replacements for older or unsuitable ships or replicas to increase and densify individual lines in order to offer more frequent departures. The reasons for this were the increased volume of cargo and improved infrastructure in the countries concerned for road or rail transport of the containers inland. Only then were the advantages of the containers fully usable in the closed cold chain .

Europe-Australia (1969)

In 1969, the shipping companies OCL and ACT started this service with reefer container ships that were equipped with on-board cooling systems and cooling rods for connection to porthole containers, such as the container ship ACT I , which could transport 326 TEU reefer containers. In 1970, Hapag-Lloyd followed with the Sydney Express (120 PR-TEU) and in 1971 the Hamburg Süd shipping company with the Columbus New Zealand class (454 PR-TEU). Individual cooling rods supplied up to 48 cooling containers and were initially arranged horizontally. In the second step, a purely vertical arrangement took place on later ships. This arrangement was very convenient for on-board operations and enabled a clear division of the containers and temperatures. This resulted in safety even with smaller loads and reduced the possibility of errors.

USA-Australia (1971)

In 1971 this container service with a high proportion of refrigerated containers was opened. The most important line was the Columbus Line , a subsidiary of Hamburg Süd . The Columbus New Zealand , the first ship in this service, was one of the largest reefer container ships in the world with 758 TEU and 454 PR-TEU. The cargo volume increased steadily and in December 1976 the fourth ship, the Columbus Victoria from the Seebeck shipyard, was put into service.

Europe-Caribbean (1976)

The CAROL service of Caribbean Overseas Lines Ltd. is a community service to which Hapag-Lloyd belongs , among others . Six structurally identical ships with 120 refrigerated containers (PR-TEU) are used; Hapag-Lloyd's Caribia Express opens this service on December 6, 1976. The round trip lasted 52 days.

The CMA CGM opened its own service with four ships with 1510 TEU, of which around 900 were PR-TEU. Mainly bananas were transported in 40-foot porthole containers.

Europe-South Africa (1977)

Container traffic between Europe and South Africa (SAECS, South-Africa-Europe-Container-Service) began in 1977 with seven ships. They had a load capacity of 50,000 tdw, connections for around 900 refrigerated containers (PR-TEU) and ran 23 knots. The German Africa Lines was involved with the Transvaal .

Europe-South America (1980/1984)

In 1980, the Hamburg Süd shipping company opened the South America service to the east coast with the ships Monte Olivia and Monte Sarmiento , mainly meat being transported as refrigerated cargo. The service is being adapted to the increasing volume of cargo with lengthened and new reefer container ships. In 1981 the Monte Rosa and the Monte Cervantes from the Seebeck shipyard followed and in 1990 the Cap class from the Flender works . In 1984 the Euro service was opened by various shipping companies from Europe and South America with five and later six ships equipped with a gantry crane. It is Hapag-Lloyd involved since 1990/91 with the Andes and the Hamburg Süd .

USA-South America (1987)

From 1987 on, refrigerated container ships operated by Hamburg-Süd in the east and west coast service under the name Columbusdienst. Initially with chartered container ships from the Offen shipping company. These ships had no cooling rods, but sockets for integral refrigerated containers.

Development of the refrigerated container

In the case of refrigerated containers, a distinction is made between the integral container with its own refrigeration unit integrated in the container and the insulated container ( porthole or CON-AIR container ), which is supplied with cold air on board or on land through two openings in the front.

Insulated container

The insulating containers initially used in the north-south routes are cooled by refrigeration systems on the ship . A distinction was made between direct and indirect systems for these refrigeration systems. In the direct systems, the air coolers in the cooling rods were designed as evaporators in which the refrigerant could evaporate. The refrigeration machines were decentralized near the cargo holds. With the indirect systems, a brine circuit was interposed and the refrigeration machines were arranged centrally in the machine room.

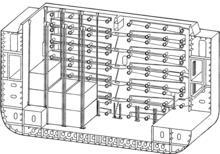

The cooling takes place through two openings on the front of the container, hence the name porthole container. The cold air flows into the container through the lower opening, the heated air exits from the upper opening. The cooling air is mainly supplied by vertical, more rarely by horizontal cooling rods. These cooling rods are insulated and divided into supply and exhaust air ducts, each cooling rod has an air cooler and circulating fan, so that one temperature can be set per cooling rod. Depending on the ship's height, five to nine containers can be connected to each cooling rod. In the meantime, the porthole containers have been replaced by the integral containers.

Integral container

Integral containers are refrigerated containers with their own refrigeration units that are operated electrically. The electricity is provided by the ship. Special reefer container sockets are installed for this. The electrical connection power for the 20-foot container is around 4 - 8 kW and for the 40-foot container around 6 - 12 kW. The electrical demand depends on the type of load, the control principle, the ambient conditions and the installed cooling capacity. The higher power is required when charging fruit, the most extreme is the power requirement when cooling down banana charges, as they are often charged with ambient temperatures. The cooling unit is arranged on the front side and blows the air cooled in the evaporator at the bottom of the container to the opposite door. The air rises between the load and is sucked in again from there. These containers are usually carried on the deck of normal container ships that are equipped with appropriate electrical connections and have sufficient capacity. On deck, refrigerated containers are only stowed two levels high. Since this refrigerated container capacity is not sufficient in the north-south sailing areas, refrigerated containers are also driven below deck, whereby additional heat dissipation is then necessary.

In the ports, there are usually also refrigerated container connections, and diesel generator sets, so-called clip-ons, are attached for land transport by truck or train .

The special features of today's refrigerated container ships are refrigerated containers below deck and a high installed electrical output. There are several options for removing heat from the condenser, such as: B. Air exchange, air / air heat exchangers, and air / water heat exchangers. The direct cooling water supply for the condensers is used by the shipping company Mærsk Line , among others .

costs

The investment costs of porthole reefer container ships are significantly higher than those of container ships with integrated reefer containers. In contrast to porthole containers, the necessary fleet of integrated containers can be leased without any problems and therefore ties up less capital.

photos

literature

- H. Linde: Transport of refrigerated cargo in containers on board container ships . In: Yearbook of the Shipbuilding Society . Vol. 65, 1971, pp. 197-223 .

- K.-H. Hochhaus, L. Idler, Y. Wild: Refrigerated containers and controlled atmosphere in ship transport (= manual of the shipyards. Volume XXI). Hansa Verlag, Hamburg 1992.

- K.-H. High-rise: technical developments for reefer container ships. In: Ship and Harbor . Volume 10, 1993, pp. 44-47.

- Y. Wild: Comparison between Porthole and Integrated reefer containers. In: Hansa . No. 4, 1994, pp. 14-22, ISSN 0017-7504 .

- F. Deichmann: Ship operations in transition - an overview of the changed requirements for the operation of the ship transport system from the perspective of a liner shipping company. STG consultation day on November 6, 1996 in Hamburg.

- K.-H. High-rise: Working group for refrigerated container shipping. In: Ship & Harbor. Volume 2, 1997, pp. 52-54.