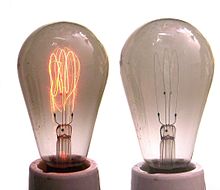

Carbon filament lamp

The carbon filament lamp was the first electric incandescent lamp whose durability, energy consumption and luminous efficacy was sufficient for practical use for everyday lighting purposes. With this type of lamp, the previously common gas light was replaced.

As a heat-resistant electrical conductor , a usually is uncoiled filament from coal used by the carbonization of a sewing thread or plant fibers was recovered.

Properties and use

Since a carbon filament can only be operated at comparatively low temperatures, the radiation maximum of carbon filament lamps is even further in the infrared range than is the case with today's incandescent lamps with tungsten filament.

However, the special color temperature is similar to that of gas light, which promoted the acceptance of the new electric light when the carbon filament lamps were introduced.

Various light bulb manufacturers still offer carbon filament lamps today because there is a demand for them because of the color temperature and the gently increasing brightness when switched on. They are used for decorative purposes and as atmospheric lighting.

Today, carbon filament lamps are also occasionally used as sources of thermal radiation, e.g. B. for incubators or terrariums .

Carbon filament lamps are more sensitive to vibrations than incandescent lamps with tungsten filaments that are common today. They don't cause inrush current like those because carbon is a thermistor .

Although the sublimation point of carbon is 3820 K higher than the melting point of tungsten at normal pressure, a strong sublimation that destroys the carbon thread starts in a vacuum at temperatures above 2000 ° C.

Historical significance of the carbon filament lamps

The carbon filament lamps were the first electrical products to be used in private households in the 1880s. This was accompanied by the construction of the electrical energy supply network.

These products therefore mark the beginning of comprehensive electrification in the cultural development of mankind.

Gas lamp manufacturers and gas suppliers lost their markets at the time, while the distribution of the newly emerging electronics market was fought hard.

The patent litigation relating to the carbon filament light bulb in Europe and the USA in the 1880s is one of the most extensive patent litigation ever held. The Edison Electric Light Co. patent lawsuit against the United States Electric Lighting Co. z. B. lasted from 1885 to 1892 and should include around 6,500 file pages. According to the Edison biographers Dyer and Martin, between 80 and 90 patent lawsuits for incandescent lamp patents and at least 125 further patent lawsuits for inventions related to the incandescent lamp in the electrotechnical infrastructure were carried out in the USA. In 1889, Edison had to set up his own division for the control and administration of the procedures. The size of the files and the long duration of these patent litigation is justified by the patent infringer's strategy of delaying proceedings. In the pending proceedings, they were able to continue producing and apparently skim off high profits to offset the legal costs. In 1893, Heinrich Göbel , who came from Germany, was the focus of patent litigation in the USA for the carbon filament lamp.

In Germany, unlike in the USA and Great Britain, there were no extensive patent litigation because the major electrical companies Deutsche Edison Gesellschaft (later AEG ) and Siemens & Halske concluded a production and price agreement for the marketing of light bulbs in 1883 and divided the market among themselves.

At that time, incandescent lamps were an expensive luxury product for hotels, offices, theaters and the wealthy in the big cities.

The manufacturers of incandescent lamps such as Edison Electric Light Co. often only allowed the incandescent lamps they manufactured to be operated on certain power supply networks, thus securing this market as well. Incandescent lamp manufacturer employees researched power generators in hotels, offices, etc. and brought legal action against the use of incandescent lamps with unlicensed power supplies.

After 1900, carbon filament lamps were replaced by incandescent lamps with tantalum filaments and later tungsten filaments.

Inventor and year of invention of the carbon filament lamp

Coal was first mentioned as a suitable fuel for electric lamps in an English patent by the inventors King and Starr in 1845. As a result, various inventors repeatedly experimented with coal. The brittle material was used in the form of pins.

Since there is neither a definition of the term carbon filament nor precise documentation about the material and properties of the carbon fuel for all developments before 1880, it is difficult to determine when carbon filament lamps were first manufactured. In patent litigation in the 1880s and 1890s, a cross section of 0.25 mm² and smaller was considered a thread. Before 1878, the developers were probably only able to manufacture and process carbon fuel elements with a cross-section in the square millimeter range. In 1874, Alexander Lodygin received a Russian patent for an incandescent lamp, which is said to be a carbon filament lamp. The specialist literature describes the glow material used by Lodygin in 1874 as carbon rods with a reduced cross-section in the middle (rods of carbon diminishing the section at the point of the luminous focus) . The developments before 1878 were experimental in character. The life of the light bulbs was generally less than ten hours.

Thomas Alva Edison is considered the inventor of the first competitive electric lighting . The patent 223,898 was issued on January 27, 1880. Since Edison already carried out lamp presentations in October 1879 with the following extensive reporting in the international press, 1879 is considered to be the year this type of lamp was invented.

Since it was the beginning of the development of incandescent lamps for everyday lighting purposes, the invention is often seen as the invention of the incandescent lamp par excellence. However, this is incorrect. Numerous patents have been granted for various constructions since 1841, which, however, were not yet competitive with gas light in terms of manufacturing costs, light output and energy costs. Both incandescent lamps with filaments and especially those with carbon filaments were known and had already been patented.

A year before Edison, the Briton Joseph Wilson Swan had already applied for a patent for a carbon filament lamp and illuminated a country house completely electrically. However, since his solution was a low-resistance carbon thread, the groundbreaking invention is attributed to Thomas Alva Edison. Although low-resistance carbon filaments are easier to manufacture, very thick copper cables must be laid in electrical networks to operate them with high currents at low voltages. Thomas Alva Edison was also able to solve the problems of the stability of a power supply network when switching consumers on and off more convincingly with the high-resistance incandescent lamps, as there was no flickering and no brightness changes in burning incandescent lamps.

Another Briton, St. George Lane Fox-Pitt , was working on the carbon filament lamp alongside Edison. Like Edison, he knew the exact requirements for incandescent lamps for their operation in electrical networks and, earlier than Edison, acquired patents for incandescent lamps that could be used in parallel in 1878. He made high-resistance filaments from grass. St. George Lane Fox-Pitt was also a philosopher and only studied light bulb technology for a few years. He later recognized that by discovering and solving the problem of gases trapped in carbon material, Edison had made a significant contribution towards making practical, long-life incandescent lamps.

Other inventors and holders of incandescent lamp patents, such as William S. Sawyer or Hiram S. Maxim , complained about an imprecise definition of the diameter of carbon threads and charcoal pencils and consequently an insufficient innovation threshold. Carbon filament lamps were actually produced based on carbon pencil patents. The United States Electric Lighting Co. was apparently founded before the Edison Society and came on the market almost at the same time as carbon filament lamps. Their chief developer Hiram S. Maxim registered numerous patents for incandescent lamp technology. However, the courts saw Edison's high-resistance, electrical-grade solution and overcoming the difficulties of making and handling fragile carbon filaments as a fundamental innovation in the art of lamp making.

The patent 223,898 "Electric Lamp", which is considered to be one of the economically and technically most important of the 19th century, is still a curiosity, because according to this patent, despite some elementary innovations, it is not possible to manufacture a permanently usable incandescent lamp, because all the specified materials for the manufacture of Filaments are unsuitable. Edison was able to hold presentation events for the useful lives achieved, demonstrate the stability of a network and convince the public of the dawning age of electric lighting. This enabled him to gain investors and supporters and to tackle his project to electrify New York. The date of invention of October 21, 1879, mentioned in traditional representations, with the breakthrough to 40 hours of use, cannot be confirmed by recent research on sources. The laboratory books on October 23, 1879 of a series of tests started on October 21, record a lamp burning time of just 14.5 hours.

It was only after an expedition to collect tropical plants and lengthy series of tests with a large number of plant fibers that the Edison Electric Light Co. found Japanese bamboo as a suitable material for making filaments. The patent 251,540 is dated December 27, 1881. The breakthrough to incandescent lamps with a burning time of up to 1000 hours came with research work on the removal of gases trapped and adhering in the carbon material. The process was also patented by Edison in patent 265,777 on October 10, 1882.

The screw sockets of incandescent lamps (so-called Edison sockets ), which are still used today, came onto the market in the 1880s together with Edison's carbon filament lamps. The solution is said to go back to an idea by Thomas Alva Edison from 1881, which he then developed together with Sigmund Bergmann in his Bergmann and Company's shop in New York. The lamp base was produced in a joint company. Bergmann sold his shares to Edison in 1889.

Edison has applied for around 200 patents relating to the carbon filament lamp and its production. Since he wanted to establish a monopoly and was less interested in licensees, it became increasingly difficult for competitors to produce products that circumvented all Edison patents.

Judge Wallace's founding 1892 judgment in the Edison patent dispute between the United States Electric Lighting Co. and Edison Electric Light Co. states:

“It was a remarkable discovery that an attenuated thread of carbon would possess all the long-sought qualities of a practical burner when maintained in a perfect vacuum. The extreme fragility of such a structure was calculated to discourage experimentation with it, and it does not detract in the least from the originality of the conception that previous patents had suggested that thin plates or pencils or small bridges could be used. The futility of hoping to maintain a burner in vacuum with any permanency had discouraged prior inventors, and Mr. Edison is entitled to the credit of obviating the mechanical difficulties which disheartened them,…. "

“It was a remarkable discovery that a thin carbon filament in a perfect vacuum had all of the long-sought properties of a practical torch. The extreme fragility of such a structure was probably one of the reasons why experiments with it were considered futile. It does not in the least detract from the originality of the concept that previous patents suggested thin plates, thin pins, or narrow bridges. The hopelessness of keeping a torch permanently in a vacuum has discouraged previous inventors, and Mr. Edison deserves the credit for having overcome the mechanical difficulties that deterred all the others ... "

In a technical report on this judgment, the term practical light is used to describe Edison's invention. The equation with incandescent lamp or carbon filament lamp is just as imprecise as the dating of the development process to a calendar year. Judge Wallace's view is well established in the history of technology.

Technical problems with the invention of the carbon filament lamp

The development of carbon filament lamps raised a number of problems that needed to be resolved in order to make a product that would function reliably.

A Europe-wide telegraph network was set up 30 years before the invention of the carbon filament lamp; many electrical inventions like the electric motor were made before the carbon filament lamp. From today's perspective, the complexity of the everyday object incandescent lamp is often underestimated. The carbon filament lamp was a high-tech product at the time of its invention and, according to Marc Greuther, curator at the Henry Ford Museum, required around 200 individual steps to manufacture.

It was not until the improvement of vacuum technology and the development of methods for the precise production of components that the breakthrough in the necessary long periods of use for commercial lamps came from 1879.

Various inventors, including Edison, had failed to develop permanently functioning incandescent lamps with platinum threads. Satisfactory light output can only be achieved near the melting point of platinum. But it was not possible to keep the temperature constant in this area and prevent it from melting through. Metals with a higher melting point than platinum were known; However, the high melting temperature required for generating light made it impossible to process it with the methods of metallurgy known at the time. Only later developments in powder metallurgy allowed the production of filaments from tungsten and other metals with a high melting temperature. Because of this, attempts were made to produce filaments from electrically conductive carbon with a high melting point. However, processing this non-metal into filaments has required the solution of numerous problems.

- Coal has a high vapor pressure. The material sublimates , which destroys the carbon thread. The condensed steam also reduces the transparency of the glass envelope. The temperature range for a useful service life with sufficient light output is small and must be set precisely.

- In contrast to metal, coal has a negative temperature coefficient . The hotter the material, the lower the resistance. Even more current flows, which leads to even greater heating and even destruction of the thread. Carbon filament lamps must have a high resistance at room temperature so that the resistance at 1900 ° C is still sufficient.

- Thin filaments of charred organic material are difficult to manufacture. In addition, the tolerances are small. At a thinner point, the carbon thread becomes hotter and material evaporates. This makes the thinner area even hotter and evaporates even faster until the thread is destroyed.

- The previously used platinum threads react more slowly with oxygen than carbon threads do. Carbon filament light bulbs therefore require a higher quality vacuum.

- The mechanical properties of carbon filaments are worse than those of the platinum filaments used previously. The brittle material is less flexible and more sensitive to shocks and vibrations. An improvement in the elastic properties requires specific manufacturing knowledge.

- There are trapped and adhering gases in the carbon material that destroy the thread at temperatures around 1900 ° C. A complex process of gradually heating and cooling the filament while venting the glass envelope must be used to remove these gases.

- When a metal wire is introduced into the vacuum enclosed by a glass bulb, leaks occur at the passage point due to different temperature coefficients . Only platinum has a coefficient that is similar to that of glass. This solution of vacuum sealing by fusing initial platinum wires into the completely fused glass envelope of a lamp was patented by Edison. Other solutions known at the time had poorer tightness, which greatly reduced the service life of the lamps due to the dwindling vacuum quality. The constructions used by competitors to circumvent the Edison patent are called “stopper lamps”. The glass bulb of these solutions is narrowed on one side and open. A plug is inserted into this neck to seal it, which at the same time supports the internal structure of the light bulb. Numerous variants of the plugs were constructed in terms of material and design. The poor quality of the “stopper lamps” due to unavoidable vacuum leaks and thus reduced durability was partially offset by the fact that the stopper could be removed from some products and the filament replaced. Renewing, cleaning the sublimation deposits and re-venting was cheaper than a new lamp.

- The necessary, non-solderable connection of a current-carrying metal wire with a very thin and fragile carbon thread must be released mechanically and electrically.

- In order to prevent a 1900 ° C hot carbon filament from destroying the current-carrying metal wire with a lower melting point, an electrically conductive thermal bridge is necessary.

- Few plants are suitable for making carbon filaments with a long shelf life. The possibility of producing thin threads from grown fibers and a homogeneous structure of these fibers are important criteria. If the grown structure is not homogeneous, the electrical resistance within the thread varies. High temperatures occur at structural breaks, which quickly destroy the thread. Amorphous carbon threads of the same size from, for example, charred wood have varying electrical resistance. Thomas Alva Edison funded an expedition to find a suitable plant for making filaments and found Japanese bamboo, the use of which he patented in 1881. Using techniques from the textile industry, Joseph Wilson Swan developed synthetic starting materials for filament production on the basis of nitrocellulose . Edward Weston developed the technique further in 1884 and introduced a filament material called Tamidine, which was used to circumvent the Edison bamboo patents. The material or variants of it later prevailed against filaments made of plant fibers. Improved electrical and mechanical properties as well as lower processing costs were decisive for this.

literature

- Arthur Aaron Bright: The electric-lamp industry: technological change and economic development from 1800 to 1947. Arno Press, New York 1972, ISBN 0-405-04690-1 .

- Frank Lewis Dyer, Thomas Commerford Martin: Edison, His Life and Inventions. Harper Brothers, 1929 ( free online edition from gutenberg.org ).

- Court decisions in the United States have been published in the Federal Reporter since 1880 . The central court decisions associated with the Edison patent are in volumes f1.47 and f1.52. The publication has also been available online as a scanned PDF file since March 2008.

- Edison Electric Light Co. v. United States Electric Lighting Co. (PDF file; 1.51 MB) Vol. 47 p. 454

- Edison Electric Light Co. v. United States Electric Lighting Co. appeal (PDF file; 2.47 MB) Vol. 52 p. 300

- Siegfried Sommer, Reinhard Welz (editor), Sonja Steiner-Welz: Technological knowledge 1900-1915: From electrical current , Vermittlerverlag, Mannheim 2003, ISBN 3-937081-12-7 , online p. 26

Individual evidence

- ↑ Patent US244277 : electric lamp. Published July 12, 1881 , inventor: Hiram S. Maxim. In free online patent: Patent 244277 "Electric Lamp"

- ^ Frank Lewis Dyer, Thomas Commerford Martin: Edison, His Life and Inventions. Harper Brothers, 1929, p. 841 ( free online edition from gutenberg.org ).

- ↑ Company brochure 100 Years of Osram , p. 15, 2006

- ↑ see, for example, Incandescent Lamp Proceedings In: The Electrical World , Vol. XXII, No. 17, August 5, 1893, p. 94

- ↑ Lodygin Museum in Tambov , (Russian)

- ↑ Patent US223898 : electric lamp. Published January 27, 1880 , inventor: Thomas Alva Edison. On free patent online: Edison Patent 223898 "Electric Lamp"

- ↑ American History via Joseph Wilson Swan

- ↑ Edward Covington: Short biography of St. George Lane Fox-Pitt. ( Memento June 10, 2017 in the Internet Archive )

- ↑ Edison's patent upheld. In: The New York Times , July 15, 1891 and October 5, 1892

- ↑ Kathleen McAuliffe: The Undiscovered World of Thomas Edison , in The Atlantic Monthly , December 1995, p. 86. Paul Israel, a senior contributor to the source research project The Papers of Thomas Edison, is quoted . The entire Eureka story is a legend. He suspects that the press' expectations for hero stories and a specific date of invention were satisfied.

- ↑ Keith A. Near, Paul Israel (ed.) Et al.: The Papers of Thomas A. Edison , Volume 5: Research to Development at Menlo Park (January 1879 - March 1881) , pp. 447-448, The Johns Hopkins University Press , Baltimore, 2004, ISBN 978-0-8018-3104-1

- ↑ Patent US251540 : carbon for electric lamps. Inventor: Thomas Alva Edison. On free patent online: Edison Patent 251540 "carbon for electric lamps"

- ↑ Patent US265777 : method of threating carbons for electric lamps. Inventor: Thomas Alva Edison. On free patent online: Edison Patent 265777

- ↑ Edward Covington: Early Edison lamp bases. ( Memento of March 17, 2017 in the Internet Archive )

- ^ Online archive of The New York Times :Edison's Patent Upheld July 15, 1891 , accessed December 1, 2007

- ↑ Patent US503670 : Incandescent electric lamp. Published August 22, 1883 , inventor: WE Nickerson (Example of a light bulb construction based on the “stopper” design.). On free patent online: WENickerson "Incendescent Electric Lamp"

- ↑ Edward Covington: Edward Weston and the filament material Tamidine. ( Memento from December 3, 2016 in the Internet Archive )