Hydrocarbon dew point

The hydrocarbon dew point (KWTP) or hydrocarbon dew point temperature is the temperature at which a state of equilibrium of condensing and evaporating hydrocarbons is established on a surface, in other words the formation of condensate is just beginning. The formation of condensate in hydrocarbons is not only dependent on pressure and temperature, but also on the composition of the gas. For example, methane has a lower dew point than ethane or acetone at the same concentration . In the case of natural gas, the hydrocarbon dew point is a very special measured variable, as a dew point of a mixed gas is measured here.

Critical condensation temperature

For the maximum dew point temperature (considered at any pressure), i.e. the critical temperature , there is the technical term "Cricondentherm" . Above this temperature the substance or the mixture can only exist in gaseous form, regardless of the pressure. The English word is occasionally Germanised in technical usage and then sometimes also used in the spelling Krikondentherm .

Special features of the natural gas dew point

The natural gas dew point is defined in the same way as the dew point of a mixture with only one condensable component, namely as the temperature above which no condensation occurs (ISO 14532). However, the condensate here is a mixture of several interacting components. The dew point is therefore not simply the maximum dew point of the individually considered vapor components.

Measurement method

Sensors

Without high accuracy, the dew point is not measured very close to equilibrium, but with a considerable but well-defined cooling rate (gradient). With all measurement methods, the measurement result depends to a large extent on either the temperature gradient or the tested gas volume, depending on the system. Although these dependencies make the results of different measurement setups less comparable, they have the advantage that the measurement results are complex, meaningful and yet comparatively quickly and easily measured parameters of the gas quality.

Modified chilled mirror

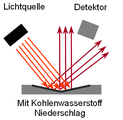

Hydrocarbon dew point sensors work similarly to dew point mirror hygrometers according to the fundamental direct measurement principle and use a temperature-controlled condensation surface to measure the dew point. However, an unmodified dew point mirror hygrometer is not suitable for measuring hydrocarbon dew points. Due to the surface tension of the condensate of the hydrocarbons, the mirror properties only change to a small extent. The properties of the hydrocarbon precipitates are similar to an oil film. Therefore, with hydrocarbon dew point sensors, one measures the scattered light from roughened surfaces, which is reduced by the formation of condensation. The effect is comparable to oiling paint that has become dull, as long as there is enough oil, there is almost no scattered light, the surface shines so that you can reflect on it. The measuring process is otherwise identical; here, too, the temperature of the reflector is measured at the time of condensation.

Dark spot sensor cell

Dark spot sensors are further developed dew point mirrors that are optimized for the detection of hydrocarbons. With sensors based on the dark spot principle, the mirror of the sensor consists of a matt metal surface with a central, conical recess. This special structure increases the sensitivity of the sensor. An intense beam of visible red light is directed onto this conical mirror and roughly focused on the central area of the recess. When dry, scattered light occurs on the matt reflector surface, which the detector registers. As usual, the mirror is now cooled down. Depending on the hydrocarbon concentration, composition and mirror temperature, precipitation occurs after a while. As soon as the reflector is wetted with a sufficient amount of hydrocarbon precipitate, the scattered light disappears and a ring-shaped reflection occurs outside the detector, the detector is now in the dark interior, in the so-called dark spot. The temperature measured at the transition from light to dark is the hydrocarbon dew point.

Gas chromatograph

The hydrocarbon dew point can also be determined indirectly by gas chromatography . For this purpose, for example, the composition of the constituents of natural gas is determined with a gas chromatograph and the KWTP belonging to this gas mixture is determined using computer models ( equations of state ).

The advantage over direct dew point measurement is the ability to calculate the entire phase behavior of the gas. In addition, the quantitative composition of the gas sample is determined in this way, from which another important quality characteristic of natural gas, the calorific value, results.

A disadvantage of this extrapolated method is that the selection of the equations of state already has a significant effect on the KWTP to be determined; the calculated dew point temperatures vary by up to 2 K. depending on the equation.

If this is disregarded, this method produces good results as long as all substances of the gas composition are recorded by the gas chromatograph. What is not a problem under optimal conditions has its limits under real conditions. For example, maintenance-related interventions or other z. For example, causes caused by the extraction site unexpected impurities and admixtures get into the natural gas sample, which are not recorded by the gas chromatograph and are therefore not included in the calculation model. The logical consequence are wrong dew points or dew points that deviate from reality. Another peculiarity of this method is that the extrapolated KWTP under laboratory conditions with synthetic gas mixtures are regularly higher than those that are determined with a dew point mirror. Under real conditions with natural gas mixtures, on the other hand, the opposite is shown, here the extrapolated dew points are lower than for measurements with dew point mirrors. The cause is probably the far more complex composition of natural gas mixtures.This behavior is likely to be due to higher hydrocarbons that are incorrectly identified, incorrectly measured or simply remain undetected, but unexpected components (such as oil or glycol) are also suspected as possible sources of error.

Individual evidence

- ↑ Petroleum Engineering: Cricondentherm, Cricondenbar and Critical Point .

- ↑ Options for the conditioning of processed biogas with liquid gas ( Memento from March 22, 2016 in the Internet Archive ) (PDF), magazine LPG 02/2013.

- ↑ Stefan v.Bose, Martin Schlüter, Peter Schmidt: Performance of Low-Temperature-Separation Natural Gas Drying Systems (PDF).

- ↑ a b Joachim Kastner, Addy Baksteen, Bernd Brendemühl: Hydrocarbon dew point measurement with EnCal 3000: Economical combination of measurement tasks in gas quality analysis . In: Elster-Instromet Journal . No. 3 , 2008, p. 12-16 ( PDF ). PDF ( Memento of the original from August 25, 2017 in the Internet Archive ) Info: The archive link was inserted automatically and has not yet been checked. Please check the original and archive link according to the instructions and then remove this notice.

- ↑ Michell Instruments: The "Dark Spot" principle .

- ↑ ISO 23874: Requirements for hydrocarbon dew point measurement with gas chromatograph.

- ↑ NPL : Report AS 3 - Comparison of methods for the measurement of hydrocarbon dew point of natural gas (PDF file; 1.3 MB), Chap. 2.12: Use of different equations of state.

- ↑ NPL : Report AS 3 - Comparison of methods for the measurement of hydrocarbon dew point of natural gas (PDF file; 1.3 MB), Chap. 5: Conclusions .

- ↑ NPL : Report AS 3 - Comparison of methods for the measurement of hydrocarbon dew point of natural gas (PDF file; 1.3 MB), Chap. 4.3.3: Comparison of 'process' instruments, ACMI - GC .