Cable laying

Wiring for the purposes of this Article, the type and design of the laying of cables and cable systems for the electrical installation in buildings.

The laying of cables and lines in buildings is regulated by standards, in particular DIN VDE 0100-520: 2013-06 and DIN VDE 0298-4: 2013-06. All permissible types of laying are summarized in Table 9 of DIN VDE 0298-4 and given the code numbers 1 to 74. To determine the required pressure and impact resistance of electrical installation pipes, the most important types of installation in buildings are listed in Table F.52-1 of DIN VDE 0100-520 as follows:

- Unprotected installation, colloquially known as "surface installation" (line, cable or protective tube remain visible).

- Underfloor installation (in screed ).

- Laying in concrete .

- Installed in cavity wall or wooden wall (in combustible materials).

- Laid in or under plaster , commonly known as " flush -laying" known.

- Installed in structural cavities.

- Installed in suspended ceilings.

- Ceiling mounting with mounting distances <0.8 m.

In the case of concealed cable laying - under plaster - in residential buildings, the cables must be routed in standardized zones in accordance with DIN 18015-3 . Restricting the laying of cables to these zones is intended to prevent the electrical cables from being accidentally damaged later.

Electrical installation pipes must comply with the DIN EN 61386 series of standards . From 1900 so-called miner pipes were used to lay cables, which were replaced from around 1950 by the evilon pipes, which were considerably easier to handle.

The minimum cross-section for permanently installed power (and lighting) circuits is specified in accordance with DIN VDE 0100-520, Table 52.2 with 1.5 mm² Cu.

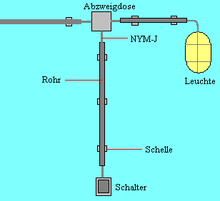

Surface installation

Visible cables are often laid in cellars, garages, storage and production halls, in the attic, etc. Today the lines are mostly routed in plastic armored conduits , cable ducts or cable platforms or trays. Cable ducts or cable platforms are chosen when a large number of cables are routed in parallel. Since cable ducts can be laid directly along the wall surface, these are the least noticeable. Lines and cables can also be attached directly to the wall or baseboard, e.g. B. with nail clamps .

For optical reasons, cables on the wall should only run vertically or horizontally and on the ceiling parallel to a wall.

Installation in the pipe

Installation pipes are usually attached to the wall and ceiling with so-called quick or snap clips. The clamps are screwed or glued to the wall. The cut tubes can then be pressed into the snap clips.

Cables or lines drawn into the pipes are exposed at bends unless special bends and branch pieces are used. The latter are also required when individual wires are pulled into the pipes.

Installation in cable duct

Plastic channels consist of a U-shaped, open channel and a snap-on cover. They are cut to the required length with a saw or angle grinder . The lower parts are attached to the wall or ceiling with dowels and screws or by gluing. An opening is cut in the duct where a cable should leave the duct.

Installation on the cable platform

Cable platforms, cable trays, cable trays or cable racks are often used in commercial or industrial buildings. They are made of galvanized sheet steel or glass-fiber reinforced, halogen-free polyester (Ebo) and are attached to hanging rails or wall brackets mounted on the ceiling. Cable trays have the advantage that further lines can easily be added later.

Which consist cable trays made of sheet steel, must as a protective measure for a electric shock if damaged insulation potential compensation in the protective measures protective earthing are included.

Condition of cables and lines

In addition to the type of insulation, the cross-section of the individual wires is the most important decision criterion when selecting cables and wires . Common conductor cross-sections for copper are 0.75 mm² (6 A ), 1.0 mm² (10 A), 1.5 mm² (16 A) and 2.5 mm² (25 A). The protection provided is indicated in brackets if the line is laid individually in plaster or under plaster on materials that conduct heat well.

The permissible load of a certain conductor cross-section depends on the type of installation (see below), the number of loaded cores in the cable, the maximum ambient temperature and the maximum permissible conductor temperature and can be found in Tables 3, 4, 5 and 6 of DIN VDE 0298-4 : 2013-06 to be taken. In many cases z. B. a 1.5 mm² is only loaded with up to 15.5 A and therefore only fused with 13 A. When choosing the cable or line and the fuse , the rule that the maximum current permissible for the respective cross-section and the application is at least as high as the nominal value of the fuse applies. In addition, minimum cross-sections are required as a criterion for mechanical strength in accordance with DIN VDE 0100-520: 2013-06, Section 524, Table 52.2. Accordingly, a minimum cross-section of 1.5 mm² applies to the fixed installation of copper lines for power circuits. In the case of long cables, a larger cross-section may have to be laid in order not to exceed the permissible voltage drop according to DIN VDE 0100-520 Section 525 and DIN 18015-1 (or also TAB).

In accordance with the planning standard DIN 18015-1: 2012-04, a three-phase connection with a current rating of at least 20 A must be provided for connecting an electric cooker (even if this is only fused with 16 A). This means that a 5 × 2.5 mm² installation cable must be laid. A connection with 5 × 1.5 mm², as used earlier, is ruled out.

Core identification of flexible and permanently installed cables according to the old standard, which was permissible until April 1, 2006, and the new standard valid from January 1, 2003:

Special requirements

- The requirements of DIN VDE 0100-520 section 528.1 and DIN VDE 0100-410 section 412.2.4 must be observed for different voltage levels in a common cable system and for protection against electric shock.

- For cable and wire systems in the vicinity of telecommunication cables, the requirements of DIN VDE 0100-520 Section 528.2 must be observed.

- For cable and line systems in the vicinity of non-electrical systems, the requirements of DIN VDE 0100-520 section 528.3 must be observed.

- DIN VDE 0100-410 section 414.4.2 must be observed for the safe separation of the cable and line systems of SELV and PELV circuits from the active parts of other circuits.

- For signal and control lines in cable and line systems, the electromagnetic compatibility to other circuits must be checked and, if necessary, a locally separated laying must be carried out.

Reference laying type

The type of reference installation according to DIN VDE 0298-4: 2013-06 Table 2 determines the permissible load (in amperes ) in undisturbed operation for cables and insulated lines in high-voltage systems for fixed installation and, as a result, the necessary protection of the line against overcurrent according to DIN VDE 0100 -430: 2010-10 Section 433.1.

| designation | Laying conditions |

|---|---|

| A1 / A2 | Laying in thermally insulated walls (A1: single core cables, and single-core cables and wires in the conduit or channel, A2: more core cable or sheath line ) |

| B1 / B2 | Laying in electrical installation pipes and ducts on or in walls or in underfloor ducts (B1: individual wires and single-wire cables and lines in installation tubes and ducts, B2: more wire cables or sheathed cables) |

| C. | Direct installation on or in solid walls (on, in or under plaster) and in cable troughs |

| D. | Laying in the ground |

| E. | Laying more core cables or more core installation lines freely in the air as well as in cable trays and brackets

with a distance to the wall that is at least 0.3 times the diameter (the conversion factors in table 22 must be observed for the accumulation) |

| F. | Laying a core cable or a core installation line freely in the air with contact with each other and a distance to the wall that at least corresponds to the diameter |

| G | Laying a core cable or a core installation line free in the air with a distance from each other and from the wall that is at least equal to the diameter |

Note: The terms sheathed cable and installation cable are used synonymously here. A wire line is single-core and, unlike a cable or a sheathed line, has no additional external insulation, so that it may only be laid in a protective tube ( electrical installation tube ) or cable duct.

Norms

- DIN VDE 0100-410: 2007-06; Erection of low-voltage systems - Part 4-41: Protective measures - Protection against electric shock

- DIN VDE 0100-520: 2013-06; Erection of low-voltage systems - Part 5-52: Selection and erection of electrical equipment - Cable and line systems.

- DIN VDE 0298-4: 2013-06; Use of cables and insulated lines for power systems - Part 4: Recommended values for the current carrying capacity of cables and lines for permanent installation in and on buildings and of flexible lines.

- DIN 18015-1: 2012-04; Electrical systems in residential buildings - Part 1: Planning principles

See also

literature

- Alfred Hösl, Roland Ayx, Hans Werner Busch: The electrical installation in accordance with regulations, residential construction, commercial industry. 18th edition, Hüthig Verlag, Heidelberg, 2003, ISBN 3-7785-2909-9

- Hans-Günter Boy, Uwe Dunkhase: Electrical installation technology The master's examination . 12th edition, Vogel Buchverlag, Oldenburg and Würzburg, 2007, ISBN 978-3-8343-3079-6

- Winfrid Hauke, Rolf Thaele, Günter Reck: RWE Energie Bau-Handbuch. 12th edition, Energie-Verlag GmbH, Heidelberg, 1998, ISBN 3-87200-700-9

- Dieter Vogt, Herbert Schmolke: Electrical installation in residential buildings. 6th edition, VDE Verlag GmbH, Berlin and Offenbach, 2005, ISBN 3-8007-2820-6

- Hans Schultke: ABC of electrical installation . 14th edition. EW Medien und Kongress GmbH, Frankfurt 2009, ISBN 978-3-8022-0969-7 .

Web links

- Comparison of the core identification with colors (PDF; 122 kB), old and new version in Switzerland

Individual evidence

- ↑ Cable and line dimensioning and selection of overcurrent protective devices. (PDF; 454 kB) Technical information. In: 2CDC400027D0101. ABB, p. 28 , archived from the original on October 13, 2016 ; accessed on November 4, 2019 .

- ↑ EnBW Energiegesellschaft, Latest News from the World of Standards Part 1 ( Memento from August 13, 2012 in the Internet Archive ) (PDF; 7.3 MB) page 20, accessed on November 4, 2019

- ↑ Cover sheet of the new standard with the two validity dates January 1, 2003 and April 1, 2006

- ↑ Technical connection conditions ( TAB ( Memento from December 8, 2015 in the Internet Archive )), Eon Bavaria, accessed in November 2019

- ↑ 'Notes on laying types and the current carrying capacity of cables and wires in the technical information from ABB, accessed in November 2015