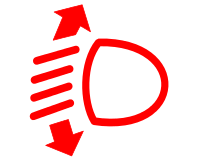

Headlight range adjustment

Under headlight range control refers to the adjustment of the light cone of a vehicle headlamp to the pitch angle , so the pitch of the motor vehicle . The aim is to always offer the driver the best possible illumination of the road without dazzling the road ahead or oncoming road users. The counterpart for the lateral adjustment is the cornering light .

causes

A change in the light cone can have various causes:

- All seats occupied, especially the back seat

- Loading the trunk

- Trailer operation

- Use of a temporary spare wheel

- Nodding movements when braking or accelerating

- Crests or depressions in the course of the road

- Emptying tank (leads to a shortening of the light cone, since the vehicle is lighter at the rear (with a tank in the rear of the vehicle) and to lengthen the light cone (with a tank in front)

Executions

Manual systems are operated by the driver. They are used to prevent long-lasting changes in the pitch angle z. B. compensate for by loading. The settings to be selected are described in the operating instructions for the vehicle. Possible designs:

- Mechanical switches are to be operated directly on the headlight, they usually require the bonnet to be opened and are usually designed in two stages as a detent.

- Electromotive, hydraulic or vacuum actuators allow adjustment while driving. The lowering can be set in stages or continuously on the dashboard.

Automatic systems work independently, they support the driver and no operation is required. They can be implemented in two different versions:

- The automatic static headlight range control regulates the pitch angle at large time intervals.

- The automatic-dynamic headlight range control also compensates for highly dynamic changes in the pitch angle, such as those that occur when braking or accelerating. The system typically responds in 300 ms. This system offers the highest level of comfort for the driver and other road users.

Details on the automatic headlight range control

Systems common today (as of 2006) consist of a sensor on the front and one on the rear axle , which measure the relative movement between the chassis and the body . The signals are used in a control unit together with the vehicle speed in order to calculate the necessary control signals for the servomotors in the headlights. Dynamic systems require more complex algorithms and faster control devices as well as powerful servomotors, usually stepper motors .

Systems based on gyro sensors or using a camera with subsequent image processing are also conceivable.

A level control of the suspension that is also located in the vehicle (e.g. hydropneumatic or air suspension ) cannot completely replace a headlight range control, as the control accuracies are different. Rather, it must be ensured that these basically competing control systems complement each other sensibly and without disruption.

Highway light

Recently, some manufacturers have also been providing the automatic headlight range control with an additional function called “ Autobahn light ”, “adaptive double- distance xenon headlights ”, “AFS 2”, “AFL Plus” or “Tri-Xenon”. The range of the (xenon) headlights is varied depending on the driving speed, taking into account the steering angle and feedback from the rain sensor. Such headlights are offered for. B. in cars from Audi, BMW, Mercedes-Benz, Opel, Saab and Skoda. They are produced u. a. from Hella. The motorway light can be realized by raising the headlights or an additional screen placed between the lamp and the lens. At the same time, the burner voltage can be increased.

The car manufacturer can use a diagnostic program to check the light distribution in motorway mode while stationary. Such manufacturer-specific diagnostic programs are not available as part of a general inspection.

The autobahn light described in this section must be distinguished from the automatic switching on of the low beam at high speeds, which z. B. at VW is also called motorway light.

Statutory Regulations

Manual headlight range adjustment from the driver's seat

Depending on the nodding behavior of the vehicle under different load conditions, at least one manual headlight range control from the driver's seat has been prescribed for all new vehicles in Germany since January 1, 1990. The behavior is determined by loading up to the maximum axle load or the permissible total weight, depending on which is reached first, for details see ECE R48, Annex 6.

In the case of particularly "hard" chassis with little spring deflection or vehicles with hydractive chassis or also with vehicles with a low maximum permissible load, the test can even show that a vehicle does not need a manual device for headlight range adjustment. All other vehicles must have at least one manual device that can be operated from the driver's seat (dashboard, center console) and that adjusts both headlights in parallel, see ECE R48, Appendix 8.

Automatic headlight range control

If the light source of a headlight exceeds a target luminous flux of 2000 lumens , the legislator mandates automatic headlight range control for the vehicle. This limit value is currently exceeded by most xenon burners, such as those used in xenon light , as well as by high-luminous flux variants of LED-based headlights. There are also variants of both types of xenon burner (e.g. 25W xenon lamps, D8 lamps) and LED-based headlights that deliberately come out just below this value and thus do not require automatic headlight range adjustment. The design alone is therefore not sufficient for an assessment.

Details can be found in the ECE regulation ECE R48.

Problems

In vehicles with manual headlight range adjustment, even a conscientious driver is faced with the problem of not always knowing the correct setting for the current load condition. In practice, headlamp leveling is rarely paid attention to, and vehicles that are tilted upwards when loaded regularly lead to glare. On the other hand, the glare that is ascribed to xenon light is often ascribed to the control oscillations of the automatic headlight range control.

literature

- Robert Bosch GmbH (Ed.): Auto electrics, auto electronics . 5th edition. Vieweg, Wiesbaden 2007, ISBN 978-3-528-23872-8 .

- Karl-Heinz Dietsche, Thomas Jäger (Red.): Kraftfahrtechnisches Taschenbuch . 25th edition, Vieweg, Wiesbaden 2003, ISBN 3-8348-0138-0 .

- Jürgen Kasedorf, Richard Koch: Service primer for vehicle electrics . 14th edition, Vogel, Würzburg 2001, ISBN 3-8023-1881-1 .

Individual evidence

- ↑ ECE regulation 48 (PDF; 1,119 kB)