Seam (textile technology)

In textile technology, a seam is the connection point between two parts that are connected by sewing . One or more threads are repeatedly passed through the sewing material, the threads being entwined with one another or with the sewing material. Seams play a crucial role in the manufacture of clothing . There are also threadless fabric connections such as glued seams and weld seams , which are not the subject of this article.

Seam connections are usually flexible, very stable and resilient, but can be loosened or corrected comparatively easily by opening. Seams can therefore also be used at transitions between elastic and inelastic fabric. You can combine different types of material, for example leather with fabric or leather with sheet metal.

Seam shapes

Due to the two-dimensional nature of the fabric, two types of seam connections can generally be distinguished: overlapped seams and butt-to-butt seams. Overlapped sewing is also known as sewing through , and butt-to-butt sewing is also known as sewing on . Sewing can be done one or more times. By adhering to this, fabric parts of unequal length can be joined without creases.

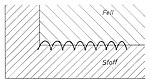

Overlapped seams

Overlapped, fully sewn seam connections are created when the fabric is laid overlapping and then "sewn through" with the thread. They are generally more durable than butt-to-butt constructions and are usually easier to manufacture. Their durability can be increased by the overlap width and number of overlaps as well as the number of seam lines and stitches, whereby thread tension and thread thickness are essential influencing factors. However, they are thicker at the connection points than the parts to be connected, which can be annoying. The classic double-overlapped, particularly durable seam is e.g. B. in trousers the lap seam on the side , which is constructed double folded into one another. The edges are protected by folding in the ends of the fabric, and turning a fabric prevents the possibility of pulling threads out of the fabric.

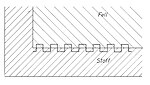

Butt-to-butt seams

Butt-to-butt seam constructions produce flat seams and are characterized by their small seam thickness. They are therefore considered to be of particularly high quality. Multi-needle machines with top thread and small stitch lengths are mostly used here. The guidance of the sewing material must be precise, as the distance between the seam lines and the end of the fabric is of crucial importance. In the case of thin, single-surface knitted fabrics that do not have a stable edge for guiding along a central edge guide, both fabric ends are often trimmed by an edge trimmer during the sewing process in order to be able to sew the cut edges precisely.

The hinge seam is a special form of flat seam . It is sewn in an overlapping manner, but the amount of thread is inserted so precisely that it no longer overlaps when "opened".

Other seam shapes

Some characteristic seam shapes are

- Viennese seam on blouses and jackets

- Salzburg plate on Lederhosen

- Grochet on jackets, coats and women's jackets

- Piping (clothing)

- Hem (textile)

Seam types

Seams are produced in many different ways, depending on the application and material properties or appearance. The following list of various hand and machine seams is not complete:

- Blind stitch

- Flatlock seam

- French seam

- Witch stitch

- Hemstitch

- Fell seam (also flat or jeans seam)

- Chains

- Knot stitch

- Buttonhole stitch

- Cross stitch

- Linen stitch

- Ladder stitch (also magic seam, invisible seam or mattress stitch )

- Piped seam

- Pricking stitch

- Satin stitch

- Point stitch

- Backstitch (also backstitch)

- Saddlery

- Hem stitch

- Hinge seam

- Buttonhole stitch (also Feston- or Languettenstich)

- Safety seam

- Tie stitch

- Mirror seam

- Relief stitch

- Lock stitch

- Stem stitch

- Darning stitch

- Overlap seam

- Overlock stitch (also overlock seam )

- Warped seam

- Pre-stitch (also basting or lock stitch)

- Zigzag seam

Furrier seams

In the Skinning inter alia, the following leather seams are prepared: appearance seam , Polish seam , Polish prongs seam , butt seam , compression seam .

Piki seam and ribbons

Fur sewing machine seam

Individual evidence

- ↑ a b c d e f g Alfons Hofer: Textile and fashion dictionary. 7th edition. Volume 2, Deutscher Fachverlag, Frankfurt am Main 1997, keyword "seam"

- ↑ Alexander Tuma: Pelz-Lexikon. Fur and rough goods. XX. Tape. Verlag Alexander Tuma, Vienna 1950. Keyword "Sewing"