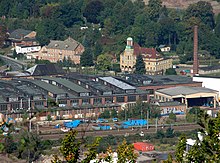

Plastic machine plant Freital

The VEB Plastmaschinen work Freital was one of seven injection molding manufacturers in the GDR, in the course of chemicalization emerged the economy of a general pump and press work and existed until the 1997th

Origins

The locksmiths Scheumann and Wolf founded a pump construction company in Döhlen in 1877 . After 1945 the company was placed under the fiduciary administration of the State of Saxony. 32 employees manufactured pumps, including the popular plunger pumps . In 1948 the company was finally expropriated and relocated to the north industrial area of Dresden . In the area of the later GDR there was no independent plastic machine construction.

The new company name "VEB Hydraulische Pressen- und Pumpenwerke" contained a reference to the future, expanded production program. The construction of hydraulic plastic presses with a pressing force of 250 to 1000 Mp was started in 1948 . In 1949 the number of employees grew to 18 employees and 12 apprentices. The relocation of operations to Freital began in 1952 and from 1953 the plant was subordinated to VVB Machine Tools and Tools (VVB WMW) under the name “VEB Pressenwerk Freital” . Other producers were assigned to VVB chemical plants or to the district-managed industry. The production of plastic machines was therefore always viewed in the VVB as a production outside the branch of industry, and never placed at the center of the scientific and technical development and the increase in production.

Political assignments

In 1954, the press factory received the party order to do political and ideological persuasion work in Fördergersdorf against farmers who were unwilling to join an agricultural production cooperative. Operational teams were formed from SED members of the company in order to drive individual farmers into a corner with arguments and to break their resistance. In 1960 all farmers in Fördergersdorf were members of an LPG. The agitators of the press plant then moved on to Kleinopitz, Pohrsdorf, Herzogswalde and Possendorf.

Start of injection molding machine construction

In response to the demand from harmonica and brush manufacturers, which were still private at the time, the plant developed the first fully hydraulic injection molding machines with piston plasticization from 1953, which were presented at the Leipzig autumn fair in 1954. They were built from 1955 and successfully tested in practice. In 1960 it turned out that a desired injection volume of 400 cm³ could no longer be achieved with a piston injection molding machine. In 1961 a screw press was switched on for the first time, made ready for series production and transferred to series production in the same year. It took 74 man hours to make a screw.

In 1956 the injection molding machines had a share of 3.7% in a turnover of 8 million marks ; this share grew to 27.5% of sales of 10.1 million M by 1958 and to 63.7% from 11.6 million M by 1960. Plastics and elastics processing machine construction became of paramount importance for the chemization of the GDR. National economy. From 1957 the plant also manufactured vacuum forming machines for shaping thermoplastic films, for example for refrigerator cladding. The workforce increased to 535 employees and 20 apprentices.

Due to a COMECON resolution on the division of labor within the Eastern Bloc , the production of vacuum forming machines was completely transferred to Hungary in 1966 . From 1958 the producer goods industry was also commissioned to manufacture consumer goods in order to compensate for the planned reduction in the number of consumer goods manufacturers. The simplest camera “ Pouva Start ”, gutter holder and hook wrench were manufactured until 1975 . Motor-driven fretsaws and taillights from 1985 to 1990 for the Trabant and Wartburg cars were produced in 1976–1984 .

Between 1962 and 1964, the intrusion or flow casting process was developed for the production of thick-walled and large molded parts. In the injection molding process, the screw itself is displaced lengthways under pressure and acts as a piston and presses the flowable mass into the tool. In the intrusion process, the mass is heated up and melted completely so that it becomes highly flowable and can be filled into the tool by the rotary movement of the screw conveyor. The molding mass can be five to ten times the shot mass of the normal injection molding machine. The machines were manufactured in slide assembly with vertically arranged component assembly. The worker remains in his place and the assembly moves. The large machines were assembled according to the product-related production series, with the worker constantly changing his workplace. The machines were developed in a modular system in accordance with a common parts strategy.

Subordinate to the VVB Plast and Elast processing machines

In order to counteract losses in real income, the Politburo of the SED decided in 1963 on a concept to change the macroeconomic steering mechanism of the GDR, which was given the name " New Economic System of Planning and Management of the National Economy (NöSPL)". This concept was implemented in 1965, and the construction of plastic machines as a structure-determining product was promoted through central planning and preferential allocation of investment funds to the manufacturers. In order to bundle capacities and potentials and for modernization, the independent branch of industry VVB Plast- und Elastververarbeitungmaschinen was formed with a scientific and technical center in Karl-Marx-Stadt . VVB Plast- und Elastververarbeitungmaschinen also included: VEB Erste Maschinenfabrik Karl-Marx-Stadt (Ermafa), VEB Werkzeugmaschinenfabrik Johanngeorgenstadt (WEMA), VEB Plastmaschinenwerk Wiehe (PMW), VEB Werkzeugbau Doberschau and VEB Modell- und Formenbau Dessau .

The scientific and technical center was a large research facility with 150 employees. From 1966, in addition to the 194 injection molding machines of that year, all screws and cylinders for the other six injection molding machine manufacturers in the GDR were manufactured centrally in the VEB Pressenwerk Freital.

In 1967 the VEB Pressenwerk Freital and VEB Maschinenbaukombinat Freital were merged to form VEB Plastmaschinenwerk Freital. The VEB Maschinenbaukombinat Freital manufactured mixers and conching machines (longitudinal graters) for the food industry and shoe gluing machines. Research and development was given a new building some distance from the Döhlen site in Potschappel . In 1972 the nationalized machine works Petzold was added as a further plant. The injection molding machines were mainly exported to Sweden, Finland, Norway, Denmark, the Netherlands, Great Britain, Egypt, Brazil, Colombia, the USSR and the Czech Republic. In 1969, 248 injection molding machines were manufactured, and thus 86.4% of sales of M 45.4 million were achieved. The factory had around 925 employees until 1990 and around 60 apprentices by 1985.

From 1969 to 1972 more machines were developed than manufactured; Injection molding machines of the large series were built at VEB Plastmaschinenwerk Schwerin. The machines developed from 1970 onwards were more powerful than their predecessors. The injection pressure, the screw piston speed, the screw piston stroke and the plasticizing performance became higher. At the same time, the first procedural influences on the injection cycle became possible, for example through variable injection speeds, stepped and later steplessly adjustable injection pressure and holding pressure. In 1970 the VVB Plast- und Elastververarbeitungmaschinen was dissolved and the Plastmachinenwerk was again more strictly regulated by the VEB Plast- und Elastververarbeitung Maschinenbaukombinat Karl-Marx-Stadt.

From 1976 to 1989, injection molding machines accounted for 96% of sales. Total production rose from M 101.9 million in 1975 to M 174.7 million in 1989. The lion's share of the 568 machines produced per year on average were exported to Comecon countries, of which the Soviet Union received the most. A smaller part remained in the GDR, another small part was exported to capitalist foreign countries. There were too few spare parts available for the GDR. In 1977, electronic data processing for planning, inventory records, operational and payroll accounting was introduced. A hot water pipeline made it possible to use the waste heat from the neighboring stainless steel plant for a paint shop.

In 1979 the VEB Plast- und Elastververarbeitungmaschinenbaukombinat Karl-Marx-Stadt was dissolved and the VEB Plastmaschinenwerk Freital was assigned to the VEB Kombinat Umformtechnik " Herbert Warnke " Erfurt. The operating part VEB Elektrowärme Tambach-Dietharz was assigned to the Plastmaschinenwerk as an operating part. Up to 1989, up to 55 employees produced 110,000 electrical heating systems for all injection molding machines manufactured in the GDR.

Escape and death in the oil tank

In September 1977 the 28 year old Wolfgang Schumann tried to leave the GDR in a narrow, 160 cm long hydraulic oil tank of an injection molding machine of the type KuASY 800/250. From 1971 to 1976 he was a development engineer in the research and development department in Freital. Because of an application to relocate to West Germany, from 1977 he was only employed as a maintenance engineer for electrical systems. For the supply of fresh air, he provided a 1.6 m long and 3.6 cm thick plastic hose, which was not sufficient. Schumann's decomposed body was discovered in November 1977 at the recipient of the machine in Kaufbeuren. The press reported in a prominent place.

Computer control

From 1980 two-color machines and two-component injection molding machines were developed, for example for the production of parts with foamed cores. From 1982 an injection molding machine with a programmable sequence control was manufactured in series.

From 1986 onwards, the factory produced injection molding machines with multi-computer control that it had developed itself and which could also be combined with a removal robot. In the same year, a fully automatic production cell was offered in which an injection molding machine was combined with a removal robot and a quick-change tool. From 1988 injection molding machines were delivered with one-bit processors and from 1990 optionally with 16-bit high-performance multiprocessors.

After the transformation, 322 injection molding machines were built between 1991 and 1997. Despite layoffs, earnings fell, so that in 1997 bankruptcy occurred. Annual sales fell from DM 50.1 million in 1993 to DM 13.6 million in 1997. The last machine was delivered in 1999. There is another company (SCHOLPP Montagetechnik GmbH) that deals with the repair and maintenance of machines.

Plant directors

- Kurt Oelschlägel 1945–1958

- Georg Wehner 1958–1966

- Karl Thiel 1967

- Helmut Auerswald 1968

- Wolfgang Hoborka 1969

- Helmut Schultz 1970–1984

- Harald Fiedler 1984–1985

- Eberhard Kittel 1986–1990

- Eberhard Kittel, managing director and Kurt Triebel, managing director 1990–1997

Honors

- Hero of Work: Werner Pawlak 1974

- Patriotic Order of Merit in Silver: Kurt Kühne 1978

- Patriotic Order of Merit in bronze: Helmut Schultz 1978; Horst Paul 1979.

literature

- Dieter Bock: The injection molding machine construction of the GDR / the historical development and its environment , Eibau 2004.

- Jan Gülzau: Border victims on the Saxon-Bavarian and Saxon-Czech border in the years 1957–1989 , (manuscript) Dresden 2012.

- André Steiner: From Plan to Plan - An Economic History of the GDR , Berlin 2007.

Individual evidence

- ↑ a b Dieter Bock, p. 33.

- ↑ a b c d Dieter Bock, p. 27.

- ↑ a b Dieter Bock, p. 34.

- ↑ Dieter Bock, p. 39.

- ↑ Dieter Bock, pp. 39–41.

- ↑ a b c d e Dieter Bock, p. 66.

- ↑ Dieter Bock, p. 35.

- ↑ a b c Dieter Bock, p. 67.

- ↑ Dieter Bock, p. 38.

- ↑ Dieter Bock, p. 42.

- ↑ a b Dieter Bock, p. 44.

- ^ André Steiner, p. 147.

- ↑ André Steiner, p. 164.

- ↑ Dieter Bock, p. 28.

- ↑ Dieter Bock, p. 63.

- ↑ a b Dieter Bock, p. 46.

- ↑ Dieter Bock, p. 49.

- ↑ Dieter Bock, p. 48.

- ↑ Dieter Bock, p. 50.

- ↑ Dieter Bock, p. 53.

- ↑ Dieter Bock, p. 56.

- ^ Jan Gülzau: Border victims on the Saxon-Bavarian and Saxon-Czech border in the years 1957–1989 , (manuscript) Dresden 2012, pp. 32–39.

- ↑ Dieter Bock, p. 52.

- ↑ Dieter Bock, pp. 57-60.

- ↑ Dieter Bock, p. 62.

- ↑ Dieter Bock, p. 69f.